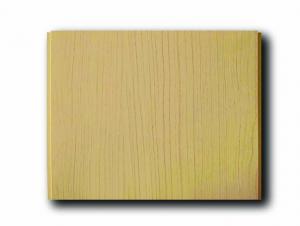

High Temperature Clear Plastic Sheet

High Temperature Clear Plastic Sheet Related Searches

Best Stainless Steel For Knives Primer For Galvanized Steel H S Code For Stainless Steel Wd 40 For Stainless Steel Spray Paint For Stainless Steel Glue For Stainless Steel Drill Bits For Stainless Steel Spray For Stainless Steel Welder For Stainless Steel Magnets For Stainless SteelHot Searches

Pvc Chairs For Sale Plastic Roof Tiles For Sale Heavy Duty Plastic Chairs For Sale Plastic Sheets For Sale Fiber Sheet Price In India Gypsum Board Price Per Sheet In India pvc pipe manufacturers in usa Stainless Steel Sheet Near Me Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Pvc Geomembrane China Geomembrane Roll Sheet Pvc Roofing Sheets Price India Pvc Roofing Sheets Price 5 8 Type X Gypsum Board Price Gypsum Board Price Per Sheet pvc resin price index Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet PriceHigh Temperature Clear Plastic Sheet Supplier & Manufacturer from China

Okorder.com is a professional High Temperature Clear Plastic Sheet supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest High Temperature Clear Plastic Sheet firm in China.Hot Products

FAQ

- One effective way to prevent chloride-induced corrosion in stainless steel sheets is by ensuring proper maintenance and cleaning. Regularly removing any accumulated chlorides and contaminants from the surface of the stainless steel sheets through thorough cleaning with mild detergents or specialized cleaning solutions can help minimize the risk of corrosion. Additionally, applying protective coatings or passivation treatments to the stainless steel sheets can create a barrier between the metal and chloride ions, further reducing the potential for corrosion.

- Yes, stainless steel sheets are suitable for pharmaceutical equipment. Stainless steel is widely used in the pharmaceutical industry due to its excellent corrosion resistance, high strength, and hygienic properties. It is easy to clean and sterilize, making it ideal for applications where cleanliness and product purity are critical. Stainless steel is also resistant to chemicals and can withstand extreme temperatures, making it suitable for various pharmaceutical processes. Additionally, stainless steel sheets can be customized in terms of thickness, size, and finish to meet specific equipment requirements. Overall, stainless steel sheets offer durability, reliability, and the necessary sanitary properties required for pharmaceutical equipment.

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is highly resistant to corrosion and can withstand the demands of storing water. It is a common material choice for water tanks due to its durability, hygiene, and longevity.

- There are several different types of stainless steel sheet finishes that are commonly used in architectural applications. These finishes are applied to the surface of the stainless steel sheet to enhance its appearance and provide additional protection against corrosion and wear. 1. No. 1 Finish: This is the most common type of stainless steel sheet finish. It is also known as "hot rolled annealed and pickled" finish. In this finish, the stainless steel sheet is hot rolled, resulting in a dull, rough surface. It is then annealed and pickled to remove any scale or impurities, leaving a clean, uniform surface. 2. No. 2B Finish: This finish is achieved by cold rolling the stainless steel sheet after it has been annealed and pickled. It results in a smooth, reflective surface with a slight grainy texture. No. 2B finish is commonly used for applications that require a high level of corrosion resistance and a polished appearance. 3. No. 4 Finish: Also known as "brushed finish," No. 4 finish is achieved by mechanically polishing the stainless steel sheet with abrasive belts or brushes. It creates a satin-like appearance with fine parallel lines. No. 4 finish is often used for decorative purposes in architectural applications such as wall panels, elevator interiors, and column covers. 4. No. 8 Mirror Finish: This finish is achieved by mechanically polishing the stainless steel sheet to a highly reflective mirror-like surface. It provides a bright, reflective appearance and is commonly used for decorative applications such as wall cladding, signage, and decorative trim. 5. Bead Blasted Finish: In this finish, the stainless steel sheet is blasted with fine glass beads to create a textured, matte surface. Bead blasted finish offers a unique aesthetic and is often used in applications where a non-reflective, tactile surface is desired, such as elevator doors, handrails, and countertops. 6. Patterned Finish: Patterned finishes are achieved by embossing or etching the stainless steel sheet with various patterns or textures. This creates a decorative surface that adds visual interest to architectural applications. Patterned finishes are commonly used for wall panels, ceiling tiles, and decorative screens. These are just a few of the most common stainless steel sheet finishes used in architectural applications. Each finish offers its own unique aesthetic and functional characteristics, allowing architects and designers to choose the most suitable finish for their specific project requirements.

- Yes, stainless steel sheets are highly suitable for wastewater treatment plants. Stainless steel is known for its corrosion resistance, durability, and ability to withstand harsh and corrosive environments, making it an ideal material for such applications. It can effectively handle the challenges posed by wastewater treatment plants, including exposure to chemicals, moisture, and high temperatures, while maintaining its structural integrity and preventing contamination.

- Indeed, the automotive industry does have the capability to employ stainless steel sheets. Owing to their remarkable strength, durability, and resistance to corrosion, stainless steel is frequently utilized in the assembly of automotive components. Exhaust systems, fuel tanks, bumpers, and trim are common examples of parts that are often crafted from this material. The utilization of stainless steel sheets grants manufacturers a great deal of flexibility in terms of design options, enabling them to fashion intricate forms and structures. Furthermore, due to its aesthetic appeal and ease of upkeep, stainless steel remains a favored choice in the automotive industry.

- Yes, stainless steel sheets are suitable for outdoor staircases. Stainless steel is a durable material that is resistant to corrosion and extreme weather conditions, making it an excellent choice for outdoor applications. Additionally, stainless steel sheets can be easily cleaned and maintained, ensuring their longevity and aesthetic appeal.

- Yes, stainless steel sheets can be used in food processing and medical applications. Stainless steel is highly resistant to corrosion and is easy to clean, making it suitable for use in environments that require strict hygiene standards such as food processing plants and medical facilities. It is also non-reactive with food and medical substances, ensuring the safety and quality of the products being processed or treated.