Geomembrana De Pvc

Geomembrana De Pvc Related Searches

Led Light Bulbs For Ceiling Fixtures Bending Machine For Pvc Profiles 42 In Ceiling Fan With Light Pvc Foil For Mdf Decorative Lights For Ceiling Ceiling Lights For Sitting Room Ceiling Brackets For Lights Ceiling With Led Lights Spotlight For Ceiling 5 Blade Ceiling Fan With LightHot Searches

Steel Mesh Panels For Sale Price For Stainless Steel Scrap Scrap Price For Stainless Steel Price For Stainless Steel Stainless Steel Plate For Sale Stainless Steel Tank For Sale Stainless Steel Sheets For Sale Cheap High Tea Sets For Sale Stainless Steel Tanks For Sale Stainless Steel For Sale High Density Fiberboard For Sale Solar Hot Water Collectors For Sale Scaffolding For Sale In Uae Scaffolding For Sale In Ireland Scaffolding For Sale In Houston Type Of Inverter For Solar Price Of Shipping Containers For Sale Types Of Inverter For Solar Stock Price For Aluminum Steel Mesh Panels For SaleGeomembrana De Pvc Supplier & Manufacturer from China

Okorder.com is a professional Geomembrana De Pvc supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Geomembrana De Pvc firm in China.Hot Products

FAQ

- What domestic PPR ball valve can withstand acid and alkali?

- Yue Yue PPR ball valve products are made of pure raw materials, mainly used in water supply and other plastic piping systems for industrial use. You can rest assured that the use of Hong Yue products

- To help explain the meaning of the ball valve Q11H-16H, combined with the actual, such valves have wood?

- JB T308-2004 valve model preparation method and "GB1048-2005 pipe element nominal pressure definition and selection", there are various types of valve interpretation:Q11H-16HQ: valve type: (Q) ball valve1: connection form: (1) internal thread1: structure form: (1) through flow channelH: sealing surface or lining material: (H) Cr13 stainless steel16: pressure code: (16) 1.6MPaH: body material: (H) Cr13 stainless steel

- Ball valve Q41f and Q11f difference, whether universal?

- Generic. The Q41F 4 stands for flanged connections, and the Q11F 1 represents the internally ribbed pipe

- Gate valve, butterfly valve, ball valve advantages and disadvantages? What other commonly used valves?

- Stop valve: a valve that closes the valve and moves along the center line of the valve seat. According to this form of valve movement, the valve seat opening change is proportional to the valve stroke. Because of the valve stem to open or close the trip is relatively short, but very reliable cut off function, and because changes in the valve seat and the valve stroke is proportional, is very suitable for flow regulation. Therefore, this type of valve is very cooperative for cutting or regulating and throttling.Advantages: in the process of opening and closing, because the friction between the valve and the sealing surface of the valve body is smaller than that of the gate valve, the utility model has the advantages of wear resistance. Second, the opening height is generally only 1/4 of the seat channel; therefore, it is much smaller than the gate valve; usually there is only one sealing surface on the valve body and the disc; therefore, the manufacturing process is better and the service is easy to maintain. Because its packing is generally a mixture of asbestos and graphite, it has a higher temperature resistance. Steam valves are normally used with stop valves.Disadvantages: as a result of the medium through the valve flow direction has changed, so the minimum flow resistance valve is higher than most other types of valves; second, due to longer travel, opening slower than the ball.

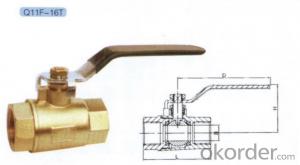

- What does copper ball valve type Q11F-16T mean?

- Q refers to the ball valve, 1 refers to the connection mode, the latter 1 refers to the straight through type, F refers to the sealing material, 16 refers to the nominal pressure of 10 times, T refers to the main material for copper material.

- What's the difference between a one piece ball valve and a two piece ball valve?

- Is the valve body is not the same. Look for a map and see

- How to distinguish between cold water valve and hot water ball valve?

- Each of the valves has a sign on which the temperature and pressure are applied.There's something wrong with your question: what's the difference between a cold water valve and a hot water ball valve?Domestic valves, such as cut-off valves, cold water using the valve core, sealing materials, rubber, that is, cold water.Ball valve sealing surface is generally PTFE, can be used for hot water.

- What are the advantages and disadvantages of the two functions of the pneumatic ball valve actuator?

- Pneumatic ball valve actuator is divided into double action and single action two modes of work.Working principle of double action mode:When the compressed air enters the middle cavity between the two pistons of the cylinder from the air inlet (2), the two pistons are separated and moved toward the two ends of the cylinder, and the air at the two ends of the air chamber is discharged through the air port (4). At the same time, the two piston rack synchronously drives the output shaft (gear) to rotate in an anticlockwise direction. On the contrary, when the air source pressure passes through the air inlet (4) into the air chamber at the end of the cylinder, the two piston moves toward the middle of the cylinder, and the air in the middle air cavity is discharged through the air port (2). At the same time, the two piston rack synchronously drives the output shaft (gear) to rotate in clockwise direction. (if the piston is mounted in opposite directions and the output shaft rotates in reverse direction, that is, double acting reverse type).