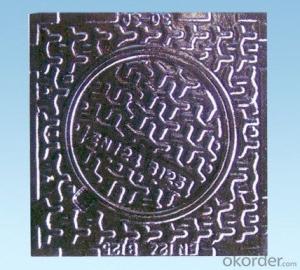

En124 D400 Specifications

En124 D400 Specifications Related Searches

Hot Searches

Inverter Size For Solar System Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Solar Panel Inverter Size Cost Of Drywall Per Sheet Large Size Aluminum Foil Aluminum Foil Market Size Solar Inverter Market Size Solar Inverter Size Chart Solar Inverter Size Aluminum Channel Stock Sizes hdpe pipe specifications polypropylene pipe specifications 1 2 Inch Type X Drywall Cost Of Drywall 1 2 Type X Drywall Metal Roof Tiles Prices Metal Furniture CompanyEn124 D400 Specifications Supplier & Manufacturer from China

Okorder.com is a professional En124 D400 Specifications supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest En124 D400 Specifications firm in China.Hot Products

FAQ

- What are the general technical requirements for casting parts?

- Satisfy appearance quality (appearance defect, quality change, size deviation)Intrinsic quality (composition, properties, internal organization)Service performance (abrasion resistance, corrosion resistance, heat resistance, pressure resistance)

- What's the density of the cast iron? The density is thin and the density is thin

- Generally cast iron thick place, density is empty, thin place density a little more.

- How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Usually manual molding optional CT11 class, ordinary machine modeling optional CT10 class, high pressure molding should reach CT9 level. The tolerances on the wall thickness of the casting are comparable to those of other dimensions of the same casting.

- What are the factors affecting the machining process of the casting material and structure?

- The impact on the machining is obvious, it should be the material and heat treatment of the castingCarbon steel parts should be treated by heat treatment (annealing) without special conditions. It can effectively prevent the uneven hardness and hard points. It is easy to turn.

- What are the casting parts used to test shrinkage holes?

- 1. anatomy. It is easy to slack off by sawing and machining.

- After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Not processed, do not understand your problem... There's something wrong with the drilling machine. Please call me

- What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Die die must charge, wood cheap, expensive aluminum mold