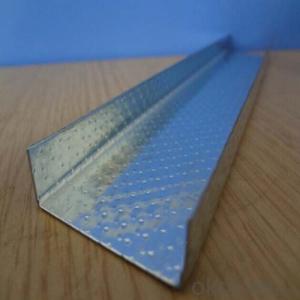

Cold Rolled C Channel Thailand

Cold Rolled C Channel Thailand Related Searches

Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Step Bit For Stainless Steel Bending Machine For Pvc Profiles Stainless Steel Bucket With Lid High Five Stainless Steel Prop Grinding Wheels For MetalHot Searches

Inverter Size For Solar System Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Large Size Aluminum Foil Aluminum Foil Market Size Solar Inverter Market Size Solar Inverter Size Chart Aluminum Channel Stock Sizes Metal Roof Tiles Prices Metal Furniture Company Type C Fuse Type C Sheetrock Geomembrane Market Size Geogrid Aperture Size Inverter Size For Solar System Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For SaleCold Rolled C Channel Thailand Supplier & Manufacturer from China

Okorder.com is a professional Cold Rolled C Channel Thailand supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Cold Rolled C Channel Thailand firm in China.Hot Products

FAQ

- Yes, steel channels are suitable for use in warehouse storage systems. They provide strong structural support and durability, making them ideal for storing heavy loads and maximizing storage capacity. Additionally, steel channels are versatile and can be easily customized to fit specific warehouse storage needs.

- Some of the different load-bearing tests conducted on steel channels include the tensile test, bending test, compression test, and shear test. These tests are conducted to evaluate the strength and durability of steel channels under different loading conditions and to ensure they meet the required specifications and standards.

- Steel channels are known to have excellent performance under impact loads. Due to their structural design and material properties, steel channels are able to effectively absorb and distribute the impact energy, thus minimizing the potential for damage or failure. The structural shape of steel channels, with their flanges and web, provides increased stiffness and rigidity, which enhances their ability to withstand impact loads. Additionally, the use of high-strength steel in the manufacturing of steel channels further enhances their impact resistance capabilities. This allows steel channels to effectively resist deformation and maintain their structural integrity even when subjected to significant impact forces. Overall, steel channels are a reliable choice for applications where impact loads are a concern, providing a high level of performance and ensuring the safety and durability of structures or systems.

- Yes, steel channels can definitely be used for aesthetic purposes in architectural designs. Their sleek and modern appearance, along with their versatility and strength, make them a popular choice for contemporary and industrial-style buildings. Steel channels can be used as decorative elements, facades, or structural features, adding a visually appealing and unique touch to the overall design.

- Can the bypass of the overhanging layer on the site be made of channel steel? How can I put the channel steel, if possible?

- Reinforcement measures shall be taken if the floor thickness is less than 120mm. 6.10.9 the cantilever beam spacing shall be set by the vertical distance of the vertical pole of the cantilever frame, and each vertical distance shall be provided with one root. 6.10.10 the outer bracing of the cantilever shall be set up from bottom to top. The scissors support shall comply with the provisions of articles 6.6.2 and 6.6.5 of this code.

- The weight per meter of different sizes of steel channels can fluctuate based on the distinct dimensions and thickness of the channels. When assessing steel channels, their height, width, and thickness are typically measured. To determine the weight per meter, you will need knowledge of the dimensions and density of the particular steel type being employed. The weight per meter can be determined by multiplying the cross-sectional area of the channel by the steel's density. For instance, let's presume we possess a steel channel with dimensions of 100mm (height) x 50mm (width) x 6mm (thickness), and the steel's density is 7.85 grams per cubic centimeter (g/cm³). Initially, let's convert the dimensions to meters: Height = 100mm = 0.1m Width = 50mm = 0.05m Thickness = 6mm = 0.006m Subsequently, compute the cross-sectional area: Area = Height x Width = 0.1m x 0.05m = 0.005 square meters (m²) Lastly, ascertain the weight per meter: Weight per meter = Area x Thickness x Density = 0.005m² x 0.006m x 7.85g/cm³ = 0.0002355 kg/m Therefore, for a steel channel with dimensions of 100mm x 50mm x 6mm, the weight per meter would be around 0.0002355 kg/m. It is crucial to note that this calculation is merely an example, and the weight per meter will fluctuate based on the specific dimensions and density of the steel being utilized.

- Yes, steel channels can be used for supporting curtain wall systems. Steel channels provide the necessary structural support and stability required for curtain wall systems, making them a commonly used choice in construction.

- Steel channels have excellent corrosion resistance properties due to the protective oxide layer that forms on their surface, which acts as a barrier against moisture, chemicals, and other corrosive substances. Additionally, their high strength and durability contribute to their ability to withstand corrosion over long periods of time.