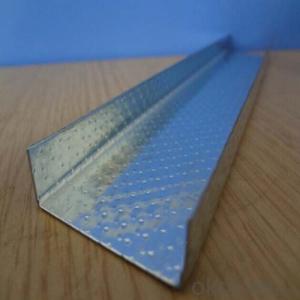

Aluminum U Shaped Channel Stock

Aluminum U Shaped Channel Stock Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Galvanized Steel Scrap Price Fiber Sheet Price In India Galvanized Steel Prices Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Geomembrane Roll Sheet Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet Price Mdf Price Per Sheet 4Mm Mdf Sheet 1220X2440Mm Price Grp Sheet Price Aluminum Sheet Stock Sizes Cost Of 4X8 Sheet Of Plywood Cost Of Drywall Per Sheet Buy Sheet PlasticAluminum U Shaped Channel Stock Supplier & Manufacturer from China

Okorder.com is a professional Aluminum U Shaped Channel Stock supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest Aluminum U Shaped Channel Stock firm in China.Hot Products

FAQ

- Yes, stainless steel angles can be used for supports and brackets as they provide excellent strength, durability, and corrosion resistance, making them suitable for various structural applications.

- In order to measure stainless steel angles, a few tools will be necessary. Initially, a tape measure or ruler will be needed to determine the length of the angle. Position the tape measure or ruler against one side of the angle and measure the distance to the opposite side. Subsequently, if the degrees of the angle are to be determined, a protractor will be required. Align the base line of the protractor with one side of the angle and observe the measurement on the inner ring of the protractor where the other side intersects. This will provide the angle in degrees. Furthermore, if the thickness of the stainless steel angle needs to be measured, a caliper or micrometer will be necessary. Position the jaws of the caliper or micrometer on opposite sides of the angle and close them until they come into contact with the steel. Observe the measurement displayed on the tool's scale to ascertain the thickness. It is crucial to ensure accuracy when measuring stainless steel angles, so it is advisable to firmly hold the tools in place and verify the measurements.

- The resistance to scaling of stainless steel angles is generally quite high. Stainless steel is known for its excellent corrosion resistance, which includes resistance to scaling or the formation of oxide layers on its surface when exposed to high temperatures or certain environments. The resistance to scaling is primarily attributed to the presence of chromium in stainless steel, which forms a passive oxide layer on the surface that acts as a protective barrier against scaling. This oxide layer, also known as a chromium-rich oxide or "passive film," is self-repairing and prevents further oxidation of the metal underneath. The degree of resistance to scaling can vary depending on the specific grade and composition of stainless steel, as well as the conditions it is exposed to. However, in general, stainless steel angles exhibit good resistance to scaling even at elevated temperatures, making them suitable for various applications where high heat or corrosive environments are a concern. It is important to note that while stainless steel offers excellent resistance to scaling, it is not completely impervious to scaling or oxidation. In certain extreme conditions, such as prolonged exposure to extremely high temperatures or highly corrosive environments, some scaling or oxidation may occur. However, compared to other materials, stainless steel angles have a significantly higher resistance to scaling, making them a preferred choice in many industries.

- Stainless steel angles have a high resistance to staining due to their unique composition. They are made primarily of iron and chromium, with other alloying elements such as nickel and molybdenum added to enhance their corrosion resistance properties. Chromium, in particular, forms a passive oxide layer on the surface of the stainless steel, which prevents the metal from reacting with oxygen and moisture in the environment. This oxide layer acts as a protective barrier against staining agents such as food, beverages, chemicals, and even fingerprints. It makes stainless steel angles highly resistant to rust, corrosion, and staining. Additionally, the smooth surface of stainless steel angles makes it difficult for stains to adhere, allowing for easy cleaning and maintenance. In applications where stain resistance is crucial, such as in kitchen countertops, laboratory equipment, and medical devices, stainless steel angles are often the material of choice due to their exceptional resistance to staining. They offer a durable and hygienic solution that maintains its aesthetic appeal even after prolonged exposure to staining agents.

- Construction commonly utilizes various types of stainless steel angle profiles. These profiles include equal angles, unequal angles, L-shaped angles, V-shaped angles, and T-shaped angles. Equal angle profiles possess legs of equal length, making them ideal for applications where symmetry or visibility of both sides is crucial. They find extensive use in framing, bracing, and support structures within construction projects. Unequal angle profiles, on the other hand, have legs of differing lengths. These profiles are suitable for situations requiring one side of the angle to be longer or shorter than the other, such as in staircases or sloping roof structures. L-shaped angles are formed by bending a single piece of stainless steel at a 90-degree angle. They are commonly employed for corner reinforcement, door and window frames, and other applications necessitating a right angle. V-shaped angle profiles possess a V-shaped cross-section and are often utilized as decorative trim or edging in construction projects. They can provide clean and finished edges on countertops, shelves, or furniture pieces. T-shaped angle profiles feature a T-shaped cross-section and are commonly used for structural purposes in construction, such as framing or supporting beams. The longer leg of the T offers additional strength and stability. These examples demonstrate the variety of stainless steel angle profiles employed in construction. The selection of a specific profile depends on the project's unique requirements, including desired strength, appearance, and functionality of the angle.

- 304 stainless steel 32mm in diameter and 3mm in thickness. How much pressure can one metre withstand? How can I calculate the pressure of a pipe?

- 304 is a versatile stainless steel which is widely used in the manufacture of equipment and parts requiring good overall performance (corrosion resistance and formability). 304 stainless steel is a brand of stainless steel produced according to the ASTM standard in the United states. 304 chromium 19%, containing nickel 9%.