3/4 X 3/8 Aluminum Bar Stock

3/4 X 3/8 Aluminum Bar Stock Related Searches

Led Light Bulbs For Ceiling Fixtures Led Lamps For Ceiling 42 In Ceiling Fan With Light Aluminum Coil Stock For Gutters Aluminum Foil For The Grill Hole Saw For Aluminum Plate Aluminum Tread Plate For Trailer Bow Plate For Aluminum Boat Aluminum Foil For Grow Room Aluminum Foil For Joint PainHot Searches

Stock Price For Aluminum Aluminum Coil Stock For Sale Aluminum Gutter Coil For Sale Used Aluminum Scaffolding For Sale 1/4 Aluminum Plate For Sale Aluminum Bar Stock For Sale Aluminum Round Stock For Sale Aluminum Diamond Plate For Sale Aluminum Scaffolding For Sale Craigslist 6061 Aluminum Plate For Sale Aluminum Dock Plate For Sale 7075 Aluminum Plate For Sale Aluminum Tread Plate For Sale Aluminum Checker Plate For Sale Aluminum Plate For Sale Near Me Plate Aluminum For Sale Aluminum Plate For Sale Aluminum Square Stock For Sale Aluminum Flat Stock For Sale Billet Aluminum Stock For Sale3/4 X 3/8 Aluminum Bar Stock Supplier & Manufacturer from China

Okorder.com is a professional 3/4 X 3/8 Aluminum Bar Stock supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 3/4 X 3/8 Aluminum Bar Stock firm in China.Hot Products

FAQ

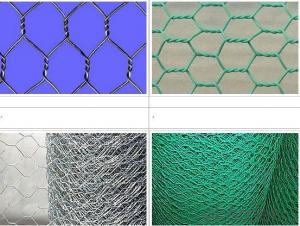

- Indeed, the utilization of steel wire mesh is viable within marine environments. Renowned for its exceptional robustness and longevity, steel proves to be a fitting option for maritime purposes, particularly when the mesh must endure arduous circumstances encompassing saltwater, turbulent waves, and corrosion. Furthermore, steel wire mesh effectively safeguards against marine creatures and debris, rendering it widely employed in marine construction, fishing nets, and aquaculture systems. Nevertheless, to bolster its efficiency and endurance amid marine settings, it is advisable to employ stainless steel wire mesh, given its unparalleled resistance to corrosion in comparison to alternative steel varieties.

- Catwalks can indeed utilize steel wire mesh. This versatile material presents numerous benefits when used in catwalk applications. Boasting a robust and enduring walking surface, steel wire mesh is fully capable of withstanding heavy loads. Its open design allows for effortless drainage, significantly reducing the risk of slipping caused by water accumulation. Moreover, this material's resistance to rust and corrosion renders it suitable for both indoor and outdoor catwalks. Customization to specific dimensions is easily achievable, and installation is swift, saving both time and effort. On the whole, steel wire mesh proves to be a dependable and cost-effective choice for catwalks, ensuring both functionality and safety.

- There are indeed drawbacks associated with the utilization of steel wire mesh. To begin with, one disadvantage lies in the relatively higher cost of steel wire mesh compared to alternative mesh materials. The inclusion of steel and the manufacturing process contribute to a higher price point for this type of mesh. Consequently, it may not be financially feasible for certain applications or projects with limited budgets. Another drawback pertains to the weight and handling difficulty of steel wire mesh, especially when dealing with large quantities. This can make installation and transportation more challenging, necessitating additional equipment or manpower. If not properly accounted for, the weight of the mesh can also strain supporting structures. Furthermore, steel wire mesh is susceptible to corrosion and rust over time, particularly when exposed to moisture or harsh environmental conditions. This can diminish the mesh's durability and lifespan, requiring more frequent replacements or repairs. Additionally, corrosion can negatively impact the mesh's appearance, resulting in an unsightly or worn-out look. Moreover, steel wire mesh may not be suitable for applications requiring a high level of flexibility or malleability. While known for its strength and rigidity, it may not easily conform to certain shapes or contours, unlike other materials. Consequently, its use may be limited in certain architectural or artistic designs. Lastly, steel wire mesh can conduct electricity, which can be a disadvantage in specific applications. In environments where electrical conductivity poses a concern, additional precautions must be taken to ensure safety and prevent electrical hazards. In conclusion, while steel wire mesh offers numerous advantages such as strength, durability, and security, it is crucial to consider these disadvantages and assess their relevance to the particular application or project at hand.

- Yes, steel wire mesh can be used effectively for creating bird or pest control barriers. Its sturdy construction and small openings make it an ideal material for preventing birds and pests from entering certain areas. The mesh acts as a physical barrier, keeping birds and pests out while still allowing airflow and visibility. Additionally, steel wire mesh is durable and long-lasting, making it a reliable option for creating bird or pest control barriers.

- Steel wire mesh is known for its exceptional strength and durability. The specific strength of steel wire mesh can vary depending on factors such as the diameter and thickness of the wire, the type of steel used, and the mesh size. However, generally speaking, steel wire mesh is incredibly strong and can withstand heavy loads and high tension. Steel wire mesh is commonly used in construction, engineering, and industrial applications where strength is crucial. It is often utilized for reinforcement purposes in concrete structures, providing added strength and stability. Additionally, steel wire mesh is commonly used as a fencing material due to its ability to resist damage from impact and external forces. The high tensile strength of steel wire mesh allows it to withstand significant pressure or stress without deforming or breaking. This makes it an ideal choice for applications that require a durable and long-lasting solution. It can withstand heavy loads, resist stretching, and maintain its structural integrity even under extreme conditions. In conclusion, steel wire mesh is renowned for its strength, making it a reliable choice for various applications where durability and stability are paramount. Its strength and resilience make it an excellent material for reinforcement, fencing, and other demanding applications.

- Steel wire mesh is known for its durability and strength, which makes it suitable for use in extreme weather conditions. In hot weather, steel wire mesh performs exceptionally well as it has a high melting point and can withstand high temperatures without losing its structural integrity. This makes it resistant to warping or sagging, ensuring that it will maintain its shape and function effectively. In cold weather, steel wire mesh remains unaffected by low temperatures, making it suitable for use in areas prone to freezing conditions or heavy snowfall. Unlike other materials that may become brittle and fragile in extreme cold, steel wire mesh retains its flexibility and strength, ensuring that it can withstand heavy loads and impacts without breaking or cracking. Steel wire mesh is also highly resistant to corrosion, which makes it an ideal choice for areas with high humidity, coastal regions, or where exposure to rain, snow, or saltwater is common. It does not rust easily, ensuring its longevity and maintaining its structural integrity even in harsh weather conditions. Moreover, steel wire mesh is highly resistant to wind and can withstand strong gusts without getting damaged. Its interlocking structure provides stability and prevents it from being easily blown away or deformed. Overall, steel wire mesh is a reliable and durable material that performs exceptionally well in extreme weather conditions. Its ability to withstand high temperatures, low temperatures, corrosion, and strong winds makes it a popular choice for various applications, such as fencing, construction, and infrastructure projects.

- Yes, steel wire mesh is generally resistant to pests or rodents. The strong and durable nature of steel makes it difficult for pests or rodents to chew through or penetrate the mesh. This makes steel wire mesh a popular choice for various applications where pest or rodent control is desired, such as in fencing, animal enclosures, or ventilation systems. Additionally, steel wire mesh can be further enhanced with galvanized coatings or special treatments that provide additional protection against corrosion and pest resistance. However, it is important to note that while steel wire mesh is generally effective in preventing pest or rodent intrusion, it is not completely foolproof and may need to be regularly inspected and maintained to ensure its integrity is not compromised.

- Steel wire mesh has high electrical conductivity properties due to the presence of metallic elements in its composition. The conductivity of steel wire mesh allows for the efficient flow of electrical current, making it suitable for various applications that require electrical conduction, such as electrical grounding, shielding, and transmission of electrical signals.