18 Gauge Galvanized Sheet Metal

18 Gauge Galvanized Sheet Metal Related Searches

Best Paint For Stainless Steel Paint For Galvanized Steel Steel Frames For Furniture Self Tapping Screws For Steel Surface Grinding Wheels For Hardened Steel Hole Saw For Stainless Steel Paint For Stainless Steel Stainless Steel For Bbq Step Bit For Stainless Steel Sponge For Stainless SteelHot Searches

Used Metal Folding Chairs For Sale Large Metal Containers For Sale Metal Shop Cabinets For Sale Metal Shipping Crates For Sale Galvanized Steel Scrap Price Fiber Sheet Price In India Galvanized Steel Prices Plastic Fiber Sheet Price Upvc Roofing Sheet Manufacturer In India China Geomembrane Roll Sheet Lasani Wood Sheet Price Rhino Roofing Sheet Price List Tinplate Sheet Price Mdf Price Per Sheet 4Mm Mdf Sheet 1220X2440Mm Price Grp Sheet Price Aluminum Sheet Stock Sizes Cost Of 4X8 Sheet Of Plywood Cost Of Drywall Per Sheet Buy Sheet Plastic18 Gauge Galvanized Sheet Metal Supplier & Manufacturer from China

Okorder.com is a professional 18 Gauge Galvanized Sheet Metal supplier & manufacturer, offers integrated one-stop services including real-time quoting and online cargo tracking. We are funded by CNBM Group, a Fortune 500 enterprise and the largest 18 Gauge Galvanized Sheet Metal firm in China.Hot Products

FAQ

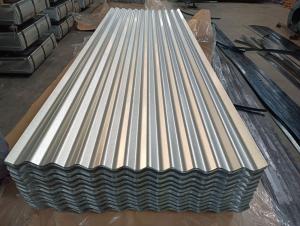

- Laminated steel sheets, which are produced by bonding multiple layers of steel with adhesive or resin, are known for their increased strength and durability. This lamination process enhances their resistance to bending, impact, and corrosion. Additionally, it reduces noise and vibration in applications like automotive bodies or construction materials. In contrast, non-laminated steel sheets consist of a single layer of steel without undergoing the lamination process. While these sheets are still robust and long-lasting, they may not possess the same level of resistance to bending, impact, and corrosion as laminated steel sheets. They are commonly used in roofing, siding, and general fabrication. The key distinction between laminated and non-laminated steel sheets lies in their composition and properties. Laminated steel sheets offer superior strength, durability, and resistance to various forces, making them ideal for demanding applications where structural integrity is crucial. On the other hand, non-laminated steel sheets are more cost-effective and suitable for applications where high strength and durability are not the primary requirements.

- The most common thicknesses of steel sheets range from 16 gauge (approximately 0.0598 inches) to 10 gauge (approximately 0.1345 inches) in industrial applications.

- Yes, steel sheets are generally resistant to water or moisture damage due to their inherent corrosion-resistant properties.

- Yes, steel sheets can be used for kitchen countertops. Steel is a durable and long-lasting material that can withstand high temperatures, making it suitable for kitchen use. It is resistant to stains, scratches, and water damage, making it easy to clean and maintain. Additionally, steel countertops can provide a sleek and modern aesthetic to any kitchen. However, it is worth noting that steel can be prone to scratches and dents, so it is important to exercise caution when using sharp utensils or heavy objects on the countertop.

- No, steel sheets are not typically used for insulation cladding. Insulation cladding is usually made of materials with thermal insulation properties such as foam boards, mineral wool, or fiberglass. These materials are chosen for their ability to reduce heat transfer and improve energy efficiency. Steel sheets, on the other hand, are commonly used for structural purposes or as a protective layer due to their strength and durability. While steel sheets can provide some level of protection, they do not possess the necessary insulation properties to effectively prevent heat or cold transfer. Therefore, it is recommended to use appropriate insulation materials specifically designed for cladding purposes.

- What's the material of ASTM A653 G30 galvanized sheet?

- ASTM A653 G30 galvanized sheet material:ASTMA653 is American Standard, equivalent to the domestic Q195 or SGCC. Hot-dip galvanized steel sheet with a coating thickness of 0.3 ounces per square inch. Material has universal specifications.

- With the correct tools and techniques, steel sheets can be easily cut. Despite its strength and durability, steel can still be cut through methods like shearing, sawing, or by utilizing plasma or laser cutting machines. The ease of cutting steel sheets is influenced by factors such as thickness and the particular type of steel employed. Generally, thinner sheets are more manageable to cut compared to thicker ones. Moreover, employing suitable cutting tools and adhering to safety precautions will guarantee a seamless and effective cutting process.