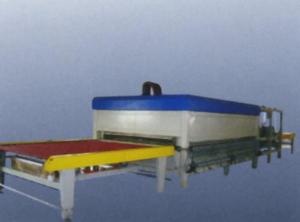

YR-6133 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Full-automatic glass double-arm and single position loading machine

1. Description of Automatic Glass Loading Machine

By digesting advanced technology abroad, combined with our R & D and innovation, the working performance of it can reach same level of best products of same type, with compact structure and high strength of machinery, and adopting bevel gear to transmit and stable travel in lifting & descending and X,Y axis, without vibration and having reliable performance. These machine adopts PLC and human interface control,with high working efficiency and low labor cost. Its features and functions are as below:

1. Controlled by PLC, imported from Japan.

2. Equip Germany vacuum system

3. Move with Linear Guide.

4. work automatically with hadraulic system, easy to operate the machine by computer.

5. The machine can know the opsition of the glass sheet automatically, and transfer the sheet to the cutting position by the roller.

2. Technical Parameter:

Max glass size: 6100*3300

Work table height: 900mm±30mm

Gross weight: 3.8T

Glass thickness:3-19mm

3. Cutting Parameter:

Linear parallelism: ≤±0.25mm/m

The diagonal accuracy: ≤±0.30mm/m

Cutting bridge speed: 0〜160m/min

Cutting bridge acceleration: ≥ 3.0m/s²

Cutting tool speed: ≥160m/min

Cutting tool acceleration: ≥ 6.0m/s²

Belt transmission speed: ≥ 40m/min

Cutting head accuracy: ≤±0.2mm

Power (installation): 380V/50HZ

Installed power: 8KW

Compressed air: 0.6Mpa

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:How much is the glass water processing equipment?

- The water glass production equipment including the equipment are as follows: water treatment equipment, autoclave mixing tank, liquid filling machine, also need to configure a bucket, a bucket, a bucket of pure ingredients, the specific details of the equipment can consult manufacturers, Wuhan Jie Rui Shi production there.

- Q:How do we polish the plexiglass after processing?

- Landlord: glass wool top with leather polishing. The specific method is. If the workpiece is bar, workpiece rotation, leather surface with a little powder grinding paste, the amount must be less. If the workpiece is not a bar, with a polishing cloth. To be stained with a little polishing wax.

- Q:What kind of equipment and adhesives are needed for plexiglass processing?

- Cutting saw polishing machine polishing machine pistol drill trichloromethane disposable syringe Pervez silicone tape ruler compasses basically are the best in a curve saw

- Q:Glass mechanical grinding, grinding wheel mesh 180, belonging to the grinding edge? What is the appearance quality?

- Because it is curtain wall engineering, four sides of the glass have rubber sealed choice, such grinding edge is possible, but the grinding wheel is too thick, the rate of finished products is affected180 the glass of the grinding wheel of the target wheel must be opaque and visible. A washing forming section, visible grinding machine, wheel configuration: No. 1, wheel 180*, No. 2, wheel 300*, wheel 3, 400--500, 2 sets of polishing wheels (resin wheel)

- Q:How do you make plexiglass?

- With a file or emery cloth for coarse grinding, chamfering and rounding with fine gauze and then polished, finally with ordinary toothpaste with a soft cloth polishing line. When grinding, pay attention to protect, good to hurt the front.

- Q:What are door and window manufacturing equipment? Want to build a windows production processing equipment factory, about how much money?

- Aluminum Alloy doors and windows equipment sawing aluminum section glass bead saw corner cutting saw automatic (semi-automatic) heavy angle automatic cutting machine (CNC / digital) numerical control double head cutting saw heavy (efficient) single head cutting saw (NC) aluminum profile cutting machine of 45 aluminum doors and windows of arbitrary angle precision CNC double head cutting saw group. NC four head angle machine (vertical and horizontal) multi angle machine end milling head profile milling machine (Dan Tou) row curtain wall Tenoing machine milling machine milling machine (five knife) stamping press bending machine hardware punch hollow glass equipment vertical insulating glass production line of glass washing machine automatic production line automatic pressure plate rolling production line of vertical insulating glass production line glass washing machine horizontal hot press laminating horizontal cold roller press hollow glass auxiliary equipment of glass washing machine horizontal hot press and horizontal Sheet cold roll press curtain wall processing equipment, planer groove, drilling equipment, aluminum curtain wall composite board, planer slot machine

- Q:How to polish plexiglass and acrylic machine after machining?

- The combustion of hydrogen and oxygen for combustion, flame, zero pollution, high production efficiency, the flame is not pure blue smoke and dust, especially suitable for polishing organic glass, acrylic and other materials, is one of the necessary equipment for making crystal characters, so it is also known as organic glass flame polishing machine

- Q:Hollow glass processing equipment vertical or horizontal good?

- Our company is all vertical, individual feel vertical, processing efficiency will be higher!

- Q:How is the inorganic fiberglass ventilating pipe produced? Is it produced by hand or by mechanical production? What equipment do you need?

- The main raw material is glass cloth and resin, first attached to the mold on a layer of glass cloth, then coated resin, layer by layer, after reaching the design thickness and shape and curing is finished.

- Q:How much money do you need to invest in making glass hot bending? What equipment should I buy?

- If big size, then large equipment to do their own simple 1830mm*2400mm*800mm to about fifteen thousand

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YR-6133 Full Automatic glass cutting machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches