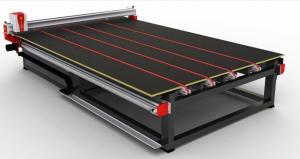

YR-4228 Full Automatic glass loading machine-Hot selling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

YR-4228 Full-automatic glass double-arm and single position loading machine

1. Description of Automatic Glass Loading Machine

The automatic loading & unloading system use variable frequency motor as drive source, to ensure smooth running and jitter-free. Transfer table uses chrome-plated shaft fitted with polyurethane wheel and synchronous belt. All main frame of equipment use Alufer welded and fitted with bolt. Electric control system of equipment use Schneider brand modules of electric; Program control uses imported SIMEINS programmable controller, fitted with touch panel.

Equipment System: main frame/ running system/ transfer system/vacuum adsorption system/mechanical turning system/high and low pressure control system/program control system.

Glass loading and unloading systems with suction cups.

2. Mechanical components:

1) turning wheel chain: high precision reinforced type

2) transfer idler wheel : PU

3) vacuum suction cup: double absorption structure

4) transfer/turning motor: Taiwan CPG motor

5) vacuum pump: PUXU( Sino-Germany)

3. Electric elements.

1) PLC controller: Delta

2) Transducer: Delta

3) Proximity switch: Swiss ELCO

4) Control cable: High-flexible shielded control cables

5) Contactor: Schneider

6) Pneumatic part: Taiwan Airtac

7) Pressure sensor: SMC

4. Technical parameter:

1) Max glass size: 4200*2800 Min glass size: 1500*1500( left side)

2) Glass thickness:3-19mm

3) Loading glass cycle: 40-90s (adjustable)

4) Transfer speed: 0-40m/min (adjustable)

5) Max rack depth: 750mm

6) Loading weight: 900KG

7) Arm quantity in one side: 4 pieces

8) Vacuum suction cups quantity on each arm: 3 pieces

9) Loading arms: double arm

10) Work position: single position

11) Power( installation): 380V/50HZ

12) Installed power: 8KW

13) Compressed air: 0.3Mpa-0.5Mpa

14) Vacuum pressure: -70 ~-90Kpa

5. Main Introduction: Automatic glass loading machine

With very sturdy frame structure, reliable vacuum system design with venturi vacuum device to prevent glass falling in case of electricity blackouts. Loading arms was driven by electrical motor.

High quality certified components to guarantee long term reliability and easy, spare parts availability.

Modular design makes future upgrades to more stations available.

6.Technical description

1) Turning mode: mechanical turning, fast speed, steady operation, loading glass thickness 3 to 19 mm. Assembled with double line turning transmission chain, to ensure the transmission process safety and reliable.

2) Turning angle: adjustable, from 95 to 98 degree.

3) Rack depth: special connecting rod retractable mechanism, suction cup move forward 150mm, and rack depth is 700mm which could meet different kinds of glass rack.

4) Induction system: two sets of photoelectric sensors to ensure safety operation.

5) Roller bar: special connecting rod retractable mechanism, to ensure the synchronous lift and separate the glass piece safely.

6) Suction system: introduced double layer suction, strong absorption.

7) Suction cup control: Every cup have separated air valve to control, choose the quantity of working cup easily and freely.

8) Lift and loading system: lift glass before loading in case the glass damaged because of sticking.

9) Alarm system: The machine has the alarm fittings, it have self inspection system and red and green alarm button.

10) Operation mode: The machine has two kinds controlling mode(automation and manual)

11) Operation screen: Color LCD touch screen interface.

12) Parameter setting: The order and glass quantity of loading can be set automatically with digital information.

7. FAQ

Q1. Can we design packaging?

Yes, but there is with quantity limitation. For 10,000 pcs, we will make the packing free for the client, and if less than 10,000 pcs, we can talk, the package is free or little money will be charged.

Q2. Can we add our logo on products?

Yes, there are several ways to do this. We can put the label of your logo on the products or make the silk print of your logo on the products. It is free.

Q3. Can we customize product?

OEM and ODM are welcomed from Anern. We have rich experiences in this area.

- Q:How much does it cost to open a glass grinding machine shop?

- If the ordinary straight side, the machine is about forty-five thousand. Beveling machine ninety-five thousand or so. Shape machine about twenty-three thousand, drilling machine about twenty-three thousand.

- Q:Just opened a glass processing plant, want to buy glass machinery, there is better

- Luoyang, of courseMany glass processing equipment is produced in Luoyang, especially the glass toughened equipment. The Randy glass machine in Luoyang is very famous in the glass deep-processing industry

- Q:Glass processing products; I do a glass processing plant, mainly to do insulating glass, I would like to ask what equipment you need to use, what price, please point out

- The manufacturers of hollow glass equipment are concentrated in Ji'nan. Among them, the best is the Ji'nan Hao hollow glass equipment factory. Its equipment is of good quality, and the price is not reasonable. The service is also good.

- Q:Method for making organic glass

- DamasceneThe organic glass blocks with different colors are cut into required geometric shapes, and are spliced and spliced on the bottom board. This method requires tight stitching, edges and corners, and a strong, yet seamless effect.

- Q:Do you use UV flatbed printers for glass processing?

- Do the glass door, glass tea table, glass printing etc., need to use UV flat-panel printers on the surface of the printed pattern.

- Q:What brand machines do you need to produce double glass? How much is the equipment? How much is the material? Can a large area do? Do you use artificial water for producing ordinary drinking glasses?

- There are few brands of machines for producing double glass. These machines are handmade by the masters, but the quality of the machines depends on the skills of the masters. There is mold, master of good workmanship, the mold out of use, and on the contrary, it is not easy to use.

- Q:Toughened glass production equipment and price

- Then you have to pay back money, inventory, rent, utilities, wages, etc.. If these are entirely new investments, about 250-300.

- Q:What are the processing methods of organic glass?

- Hot bending: shape shapes of organic glass through high temperatures.(1) hot bending method:Clamp the heating with a flat fixture.Hot air gun: heating is not uniform, easy residual uneven cooling caused by thermal stress, days after the easy deformation.Constant temperature furnace: the temperature is relatively average, and the temperature is more uniform when cooled.(2) the temperature and time of setting and tempering of plexiglass after heating:Generally use PMMA, 65-70 degrees, 3-5 hours (hot air heating method)Heat resistant with PMMA, 75-80 degrees, 3-5 hours (hot air heating method)Note: this treatment is to eliminate the residual molding forming residual stress, improve the size stability after the change; mechanical properties; improve the dimensional accuracy, or reduce the deformation.

- Q:How is the inorganic fiberglass ventilating pipe produced? Is it produced by hand or by mechanical production? What equipment do you need?

- The main raw material is glass cloth and resin, first attached to the mold on a layer of glass cloth, then coated resin, layer by layer, after reaching the design thickness and shape and curing is finished.

- Q:Can plexiglass be machined with CNC milling machines?

- Using CNC milling machines to make plexiglass is too wasteful.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

YR-4228 Full Automatic glass loading machine-Hot selling Machine

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 45 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches