WDS Low Conductivity Microporous Insulation Board Temperature Reduction from 950 to 240℃

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4480 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Microporous Insulation Board:

CMDS Microporous Insulation Board is specially designed for steel industry & metallurgy with very good thermal and mechanical properties. The formulation is an opacified blend of filament reinforced pyrogenic silica. The coverings is water repellent to assure the stability of the microporous board when moisture may occur due to castables, mortar etc.

2.Main features of Microporous Insulation Board:

◆ Extremely low thermal conductivity ◆High compressive strength

◆ High thermal stability ◆Environment protection

◆ Easy to handle ◆No harmful inhalable fibers

◆ Resist most chemical attacks ◆Free of organic binders

◆ Non combustible

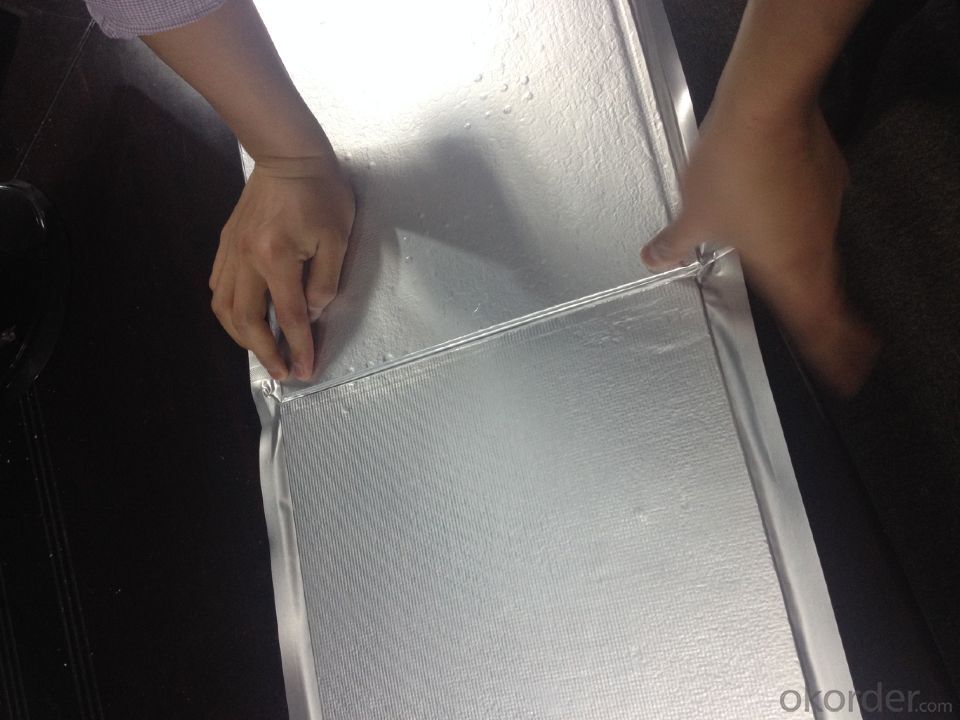

3. Microporous Insulation Board Images:

4. Microporous Insulation Board Technical Parameters

CMDS Microporous Insulation Board can be shaped easily with a simple cutter and taped off with aluminum tape. The board can be fixed in place with the same adhensives that are used for refractory lining.

Application: Ladle, Torpedo Ladle, EAF, Degassers, Cement Rotary Kiln, Ceramic Firing Klin, Aluminum Melting and Holding Furnace and so on. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our board?

A world class manufacturer & supplier of Microporous Insulation Board is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:What is PE waterproof cloth and PVC tarpaulin

- The characteristics and performance index of waterproof cloth products 1. Tensile strength index: warp strength ≥ 2100N / 5CM, zonal strength ≥ 1600N / 5CM; 2. No leakage of water, water pressure ≥ 2000MM water column; 3. Low temperature, cold temperature -20 ℃; 4 Can be mildew, mildew experiment for the first level. Product Usage 1. Can be used car, train, ship cargo tarpaulin; 2. It can be used for the open storage of the harbor airport at the station terminal harbor; 3. Can be set up temporary granary and a variety of crops covered with open-air; 4. Can be used for construction site power construction site and other sites to build temporary shed, temporary warehouse materials; 5. Can be processed camping with tents and various machinery and equipment outside the jacket.

- Q:How can the toilet waterproof works fail?

- Can only do a new waterproof, and now have engaged in the base of the waterproof coating, the effect is very good. It is best to ask professionals to do their own difficult.

- Q:Cabinet is to buy finished products, or directly to the decoration company to do?

- Finished products to buy relatively easy to do some of the cabinet to do more solid material more assured because the plate is also a long-term environmental protection or woodworking directly do better feel that the company can quote their own under the woodworker comparison

- Q:Oriental rain rain waterproof how to

- Strict selection and the pursuit of excellence in product performance of the East Rainbow waterproof coating long-term waterproof material in the market leading the main reason. In order to test product performance, the East Rainbow company to the product to the plateau, desert, alpine, high temperature and other areas for testing.

- Q:I would like to ask how to do in the warm water above,

- Rough housing or liquid with a good, airtight than the coil is good, all-pervasive, if there is a trachoma in the case of white do not see the white. If the building from the building if the first waterproof, finished product protection is a problem.

- Q:How does the finished ventilator manufacturer waterproof?

- In the latest country set JJCJ33 clearly stipulates that the structure to be waterproof, refers to the internal ventilation of all nodes and ventilators and roof all the nodes,

- Q:Self-built concrete house finished three years after the use of large-scale housing wall leakage how to do?

- Third, from the indoor water leakage area for waterproof maintenance.

- Q:Roof membrane waterproof construction process, what should be noted that?

- Three do 1 to do concrete or mortar ratio is accurate 2 to do the surface of the second calendering 3 to be fully maintained

- Q:Js waterproof coating without powder can brushing

- 5. Coating maintenance: JS cement-based waterproof emulsion coating construction after 24 hours after the end with a damp cloth to cover the coating or spray water to maintain the coating, usually 2-3 days; air humidity, poor ventilation of the local dry The time period may be longer, and vice versa; 6. Check the construction of JS waterproof coating (closed water test): bathroom, pool and other parts in the JS cement-based waterproof emulsion waterproof layer after dry (at least 24 hours in summer, at least 48 hours in winter) stored water for 48 hours to see the water Construction is not qualified. Light wall must do the water test. JS waterproof coating See the amount of: under normal circumstances, the amount of about 0.6-1kg / ㎡, the actual amount from the use, the use of parts, rough surface roughness, environmental factors such as the decision.

- Q:Do you use the waterproof material on the building to be harmful to the human body?

- Your pores, the respiratory tract, the lungs, will be hurt, when young do not feel out, the consequences more powerful than smoking.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

WDS Low Conductivity Microporous Insulation Board Temperature Reduction from 950 to 240℃

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4480 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords