Virgin Polypropylene Reinforced Concrete Fiber

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

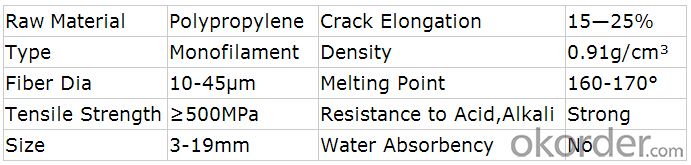

1,Specification of Virgin Polypropylene Reinforced Concrete Fiber

2,Introduction of Virgin Polypropylene Reinforced Concrete Fiber

Polypropylene fiber is also called engineering fiber, concrete fiber, anti-cracking fiber,synthetic fiber or plastic fiber.

We use high tenacity polypropylene resin as the raw material and produce with special technics. Putting the pp fiber into concrete or mortar can control the microcrack caused by such factors as the plasticity contraction, air shrinkage and temperature change. Great prevention of cracks-being, improvement of the features of anti-cracks and permeation-resistance, shock and earthquake proof, all these have been good evidence for the wide usage of pp fiber--finish coat of road and bridge, mining and tunnel construction, railroad, high-rise building, consolidation of side, fire-protection infrastructure, concrete-mending, industrial civil use engineering, wall, basement, waterproof project of pool and roof garden, kinds of prefabricate concrete products etc.

3, Package of PP Staple fiber

1kg/plastic bag, 20pastic bags/woven bag.

1x20' QTY: 9-10 Tons

1x40HQ QTY: 22-23Tons

allowing more or less clause.

4, Images of the Fiber

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1>How about your company?

A manufacturer & supplier focuses on the production of PP related product that used as the raw material of textile, automotive interior and constuction projects etc. Have been in this field for many years, with rich experience.

2> What's the MOQ?

1x20'GP or1x40'HQ will be better as the price would be economical based on full container load.

3>How long can we receive the product after purchase?

It takes about 1 to 2 weeks to finish the production based on the specific production schedual. Then it will depend on the shipping time from loading port to the destination port.

- Q:What is the designated outer fiber?

- The fiber especially in heat resistance and chemical resistance than that of spandex fiber, so you can consider developing spandex fiber due to physical reasons and is not involved in the application.The company uses DOW's new polymer based on its original original polymer and combines its own yarn making technology into production. The basic patent belongs to DOW corporation.

- Q:What is fiber binding force?

- For the tow two, the low cohesion force causes the increase of the width of the tow, which is unfavorable to the processing of the strip.The unique tooth like structure of dry spun acrylic fiber makes cohesion become an important index to influence the spinnability of fiber.

- Q:What are polyester fibers and washing methods?

- Like other synthetic fibers, polyester fibers do not carry dirt as easily as natural fibers because of processing methods. Its hydrophobic properties on the surface reject hydrophilic dirt, but oil stains can easily cause spots, or even penetrate into the interior of the fiber, making it time and heat to wash them away. The removal of dye staining on the polyester fiber, are the main factors to consider when designing the detergent. Polyester and cotton blend very well, usually polyester ratio of 40%~60%, and wool and wool blend ratio is slightly smaller. Natural fibers have a good feel and comfort, and moisture absorption, but polyester fiber is not. The blend is made from ready made blends rather than monofilament.Like other synthetic fibers, polyester fibers do not require heavy-duty detergents. Its hydrophobic properties have strong resistance to water solubility, whether it is acid or alkali. Pay attention to the lipophilicity of polyester fiber when designing detergent.

- Q:100% polyester fabric clothing, there is a special laundry method?

- Polyester is acid, non alkali, and if you insist on washing machine, you can set a laundry bag, with neutral laundry detergent.

- Q:Cotton and polyester blended fabrics are better for warmth and comfort than cotton.

- Warmth retention is better than cotton. If the market is only the conventional varieties of cotton, warmth and comfort is much better than polyester cotton blended cotton fabric; but easy to wrinkle, not good-looking appearance; and polyester cotton blended fabrics, cotton with warmth and comfort, but also make the appearance more beautiful, and not easy to wrinkle.

- Q:What are the elastic fibers and collagen fibers?

- Collagen fibers (collagenous, fiber) collagen fibers are arranged in bundles of loose connective tissue, interwoven with each other, and the fiber bundles are often branched. The fiber has tenacity and good traction resistance. Collagen fibrils were composed of finer fibrils (microfibrils) by electron microscopy. The micro fibril has a special transverse band with a period of 64nm. Each micro fibril has a sequence of light and shade. In comparison with dark band chemical root more free, so more electron microscopic retention stain of collagen fibers: pink, fasciculate, fibrils most of them can not see; collagen fiber mainly containing collagen, amino acid glycine, proline and hydroxyproline. Collagen is the only protein with more hydroxyproline. Therefore, the determination of hydroxyproline can determine the content of collagen in tissues. Collagen accounts for 30% of whole body protein. Protein molecules polymerized into collagen fibrils are called procollagen molecules. Collagen fiber is the most widely distributed and most widely used fiber in three fibers. Widely distributed in various organs. The skin, sclera, and tendon are the most abundant. The staining of collagen fibers is mainly used for the identification of muscle fibers. In children, the proportion of gum fibers in bones is large, and osteoblasts are very active in the manufacture of bone. As a result, children have large bone elasticity and are not easily broken.

- Q:What material is bamboo fiber?

- Bamboo fiber is a kind of cellulose fiber extracted from natural bamboo. It is the fifth natural fiber after cotton, hemp, wool and silk. Bamboo fiber has the characteristics of good air permeability, instant water absorption, strong abrasion resistance and good dyeing property. Meanwhile, it has the functions of natural antibacterial, bacteriostasis, mite removal, deodorization and anti ultraviolet. Experts point out that bamboo fiber is a kind of natural environmental friendly green fiber in the true sense

- Q:The towel / towel in the bamboo fiber is getting stiff. How do you get back to the original softness?

- Wet towel and add salt water scrubbing, in addition to salt water, can play a role of course is the cooking or washing towels, in brine, so that not only is a towel from the new towel is also become soft, bacteria disappeared.

- Q:The difference between high elastic carbon fiber and high rigidity carbon fiber bat

- Under the same force, high elasticity means that the elongation of the fiber is relatively large, and the high rigidity means that the elongation is relatively small.

- Q:Compared with the traditional reinforcement technology, the reinforcement effect of CFRP sheets is different from the traditional reinforcement technology What's the price of carbon fiber reinforcement?

- Carbon fiber reinforcement in the slab reinforcement per square price, the price of carbon fiber reinforcement to determine from the following aspects, the degree of difficulty of the construction of Gongyi carbon fiber reinforced carbon fiber prices between 220--380 reinforcement, carbon fiber reinforcement for many teams, the construction is not difficult, the main problem is a waste of time of carbon fiber reinforcement some other auxiliary process time, the final carbon fiber reinforcement, it is pasted carbon fiber cloth, cloth but when carbon fiber reinforcement has completed the preparatory work.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Virgin Polypropylene Reinforced Concrete Fiber

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords