Vibration feeder hopper useused in military and chemical industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

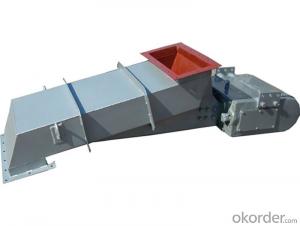

Vibration feeder hopper useused in military and chemical industry

Introduction Overview:

WGZD vibration hopper is a new feeding device for hopper arch breaking, which is installed in the bottom of stock bin. It is used for arch breaking and uniform feeding, and to solve the problem of material storage difficulties. Suitable for any types of storage bin, such as round, square, steel or concrete.

Application:

Widely used in military and chemical industry, machinery and metallurgy, ceramics, grain and food, plastic industry, wood, building materials, environmental protection and agriculture.

Advantages:

1.The material can discharge continuously and smoothly, no flow material occlusion and particle size segregation.

2.The bin height can be reduced greatly, is advantageous to the factory craft arrangement.

3.With simple structure, reliable operation, stable operation.

4.Less power consumption, long service life, maintenance is simple.

5.The discharge amount is stable in + 5%;

6.Equipped with electrical control equipment, no parking impact.

7.Environmentally friendly: can achieve completely sealed transport, no dust overflow.

Technical parameter table:

Model | Hopper Diameter (mm) | Diameter of matched silo (mm) | Reference flow | Motor Power (kw) | Vibration power (KW) | Maximum material (mm) | Single weight (kg) | |

cement | Raw material | |||||||

GZD04 | 400 | 200-400 | 6-13 | 4-7 | 0.15 | 0-9.5 | 15 | 132 |

GZD06 | 600 | 300-600 | 8-20 | 7-13 | 0.25 | 0-2.5 | 20 | 185 |

GZD08 | 800 | 400-800 | 35-50 | 15-30 | 0.4 | 0-5 | 22 | 322 |

GZD10 | 1000 | 500-1000 | 50-80 | 20-50 | 0.75 | 0-8 | 28 | 430 |

GZD12 | 1200 | 600-1200 | 50-100 | 30-70 | 1.5 | 0-16 | 32 | 510 |

GZD15 | 1500 | 700-1400 | 60-120 | 40-80 | 1.5 | 0-16 | 35 | 650 |

GZD20 | 2000 | 800-2000 | 80-160 | 60-100 | 2*1.5 | 2*1.5 | 42 | 1310 |

- Q:The opening process of press filter from feeding to discharging is described briefly

- Start and close the filter press.Open the feed valve.Starting feed pump.Control feed pressure or time, or two at the same time, to the set value, stop feeding.Close feed valve.With diaphragm extrusion equipment, start the diaphragm extrusion pump, correctly open the valve of each extrusion system, control the extrusion pressure, and then stop the extrusion after the setting value.Slow release of extrusion pressure, generally to about 7bar, stop pressure release.

- Q:How to choose crushing equipment suitable for its own ore material?

- Attention should be paid to the size of the feed port of the crushing equipment and the size of the feed size, whether it matches the material, such as whether the material can enter the machine and produce it smoothly

- Q:What's the simplest ore radio to do?

- The most simple ore radio, a three meters above the overhead antenna, a ground wire, a 2AP9 diode, a high impedance diode in parallel with the headset, headset received two world online, only listen to the strongest local Taiwan, if there is more than a strong one mix together.

- Q:Which God knows, hammer crusher, according to the material into which there are several categories?

- Tangential feed -- from tangential direction is fed into the crushing chamber, the common good, not only crushed grain, also crushed small cake and chopped stalk and forage.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vibration feeder hopper useused in military and chemical industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords