Stitching Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000吨 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

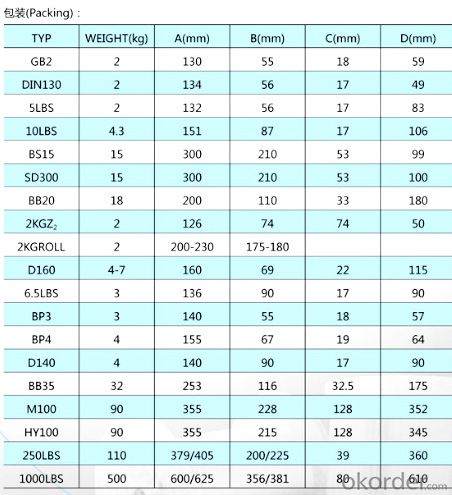

| Commercial use: | Used for making staples,paper clip、material wire for binding paper and books |

| Tensile strength: | 925 to 1130 N/mm2 and 1000-1200N/mm2 and specical up to requirements |

| Wire diameter: | 0.4-0.45-0.50-0.55-0.60-0.70-0.80-0.90-1.00mm |

| Tolerance: | ±0.01mm |

| Zinc coating: | 8-16g/m2 |

Application:

| |

| |

|

- Q:What's the printing process for PC material? Is the print content on PC or other surfaces?

- Roll material, screen printing or rotary printing (relatively few, only for thickness below 0.125MM), printing the same as above.

- Q:What are the allowable quantity differences in printed packaging materials?

- The ink thickness, three-dimensional sense of common offset and letterpress 5 microns to about 12 microns in gravure printing, flexo printing ink layer (aniline) is 10 microns thick, and the wire net printing ink thickness than the ink layer thickness is generally up to about 30 microns. Thick screen printing special printed circuit board, ink film thickness of up to 1000 microns. Foam ink printing Braille, foaming layer thickness of up to 300 microns. Screen printing ink layer thickness, printing texture rich, three-dimensional feeling strong, this is other printing methods can not match. Screen printing can not only print in monochrome, but also capture and screen color printing.

- Q:Carton printing process and materials

- Flexo printing and gravure printing of corrugated carton processThese two processes are the first to roll paper printing paper, and then in the automatic corrugated cardboard production line to complete the production of corrugated cardboard. Carton printing quality and molding quality are relatively high, but the investment is relatively large, it is also not suitable for small batch production.In the domestic carton industry, three conventional corrugated carton printing methods are more common, and become the mainstream of corrugated box printing. And the new printing box system, due to equipment, materials, processes, operations and other technical hot spots have not yet been fully mastered, the investment is relatively large, the promotion of the difficulty is still relatively large. But in order to improve the quality of carton enterprises, reduce the total cost of cartons, to maximize profits and increase the competitive advantage in the market, it is imperative to adopt the new printing process.

- Q:What are the materials used in screen printing?

- The range of screen printing applications is very extensive. In addition to water and air (including other liquids and gases), any object can be used as a substrate. Some people have evaluated silk screen printing as saying: "if you want to find the ideal printing method on the earth to achieve the purpose of printing, it is probably screen printing method.".

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stitching Wire

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 1000吨 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches