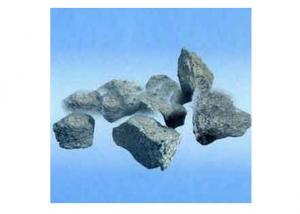

Steelmaking Magnesium Ferrosilicon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 500 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

Magnesium Ferrosilicon is used as deoxidizer in foundry . Our products with high quality and high stablity characteristics .

We are a professional producer of nodulizer , inoculant and vermiculizer . We have exported our products all over the world , winning the fine reputation by first-class quality and professional service .

Chemical Composition :

Re |

Mg |

Ca |

Si |

Mn |

Ti |

Fe | |

1 |

0.5-2.0 |

5.0-7.0 |

1.5-3.0 |

44max |

1.0max |

1.0max |

Balance |

2 |

0.5-2.0 |

6.0-8.0 |

1.5max |

44max |

1.0max |

1.0max |

Balance |

3 |

2.0-4.0 |

6.0-8.0 |

2.0-3.5 |

44max |

1.0max |

1.0max |

Balance |

4 |

2.0-4.0 |

7.0-9.0 |

2.0max |

44max |

1.0max |

1.0max |

Balance |

5 |

2.0-4.0 |

7.0-9.0 |

2.0-3.5 |

44max |

1.0max |

1.0max |

Balance |

6 |

4.0-6.0 |

7.0-9.0 |

3.0max |

44max |

2.0max |

1.0max |

Balance |

7 |

6.0-8.0 |

7.0-9.0 |

3.0max |

44max |

2.0max |

1.0max |

Balance |

8 |

6.0-8.0 |

9.0-11.0 |

3.0max |

44max |

2.0max |

1.0max |

Balance |

9 |

8.0-10.0 |

8.0-10.0 |

3.0max |

44max |

2.0max |

1.0max |

Balance |

Size : 2-12mm , 5-15mm , 5-25mm , 10-30mm .

Packing : 25kg bag in 1MT big bag

Note : All the composition of each element , other special elements do not be mentioned above , size and packing can be adjusted upon request .

- Q:Pink and what is the difference between rare earth polishing powder

- Information, biology, new materials, new energy, space and oceans are pushing for the contemporary scientists six new technology research group, rare earth, rare earth, rare earth, attention is the development for the rare earth elements have to display their skills in the six science and Technology Group in the world. However, rare earth elements are, after all, a group of elements that are not yet fully understood, which requires great efforts to study and understand them so as to hold them and make greater contributions to mankind.

- Q:What's the use of rare earth?

- Is the chemistry of rare earth elements in the periodic table lanthanides (La) cerium, lanthanum, praseodymium (Ce) (Pr), neodymium (Nd), promethium (Pm), samarium (Sm) and europium (Eu), gadolinium (Gd), terbium (Tb), dysprosium, holmium (Ho (Dy)), ER (Er), (Tm), thulium ytterbium lutetium (Yb), (Lu), and 15 with lanthanide two elements closely related to scandium (Sc) and yttrium (Y) a total of 17 kinds of elements known as rare earth elements (Rare, Earth). Rare earths (RE or R). Rare earth (rare, earth) has "industrial vitamins" laudatory name. Now it has become a very important strategic resource. Rare earth oxide refers to the elements in the periodic table of atomic number from 57 to 71 of the 15 Lanthanide Oxides, as well as with the lanthanide elements similar to the chemical properties of scandium (Sc) and yttrium (Y) oxides of 17 elements. Rare earth elements have been widely used in the fields of petroleum, chemical, metallurgy, textile, ceramics, glass, permanent magnet materials, with the continuous progress of science and technology breakthrough and application technology, rare earth oxide value will become more and more large.

- Q:Rare earth in the end what to do ah?

- Rare earth is generally separated from the oxide state, although the earth's reserves are very large, but smelting and purification difficult, it seems relatively rare, named after rare earth. In general, rare earths on earth exist in the form of rare earth oxides.

- Q:Use of rare earth? Which industries depend on him?

- The catalyst with molecular sieve made of rare earth, has the advantages of high activity, good selectivity and strong resistance to heavy metal poisoning, which replaces the aluminum silicate catalyst used in petroleum catalytic cracking process; in ammonia production process, with a small amount of rare earth nitrate as catalyst, the gas volume is 1.5 times bigger than in Ni Al catalyst; synthesis of isoprene rubber and butadiene rubber in the process of using naphthenic acid rare earth aluminum products three kinds of catalyst, the obtained performance is excellent, with less equipment fubberized, stable operation, postprocessing the advantages of short process; composite rare earth oxides can also be used as an internal combustion engine exhaust purification catalysts, cerium naphthenate is also used as a paint drier etc..

- Q:What's the use of rare earth? Why Japan wants to buy Chinese rare earth?

- Rare earth ferrosilicon alloy, rare earth silicon magnesium alloy as spheroidizing agent in the production of rare earth nodular cast iron, ductile cast iron, because this is particularly suitable for the production of the special requirements of the complex ductile iron, are widely used in automobile, tractor, diesel engine and other mechanical manufacturing; rare earth metals added to magnesium, aluminum, copper, zinc, nickel, etc. non-ferrous alloys, physical and chemical properties of the alloys can be improved, and improve the mechanical properties of alloy at room temperature and high temperature. Made of rare earth molecular sieve catalyst in petroleum chemical industry, has the advantages of high activity, good selectivity and strong resistance to heavy metal poisoning, which replaces the aluminum silicate catalyst used in petroleum catalytic cracking process; in ammonia production process, with a small amount of rare earth nitrate as catalyst, its treatment capacity than Ni Al catalyst 1.5 times; in cis-1,4-polybutadiene rubber and isoprene rubber in the process of using naphthenic acid rare earth aluminum products three kinds of catalyst, the obtained performance is excellent, with less equipment fubberized, stable operation, postprocessing the advantages of short process; composite rare earth oxides can also be used as an internal combustion engine exhaust purification catalysts, cerium naphthenate also can be used as paint drying agent.

- Q:Method for processing rare earth ore

- A carbon workshop: add ammonium chloride nitrate compounds, rare earth carbonate travel. This rare earth carbonate can also be sold, but it's small.

- Q:Why should China export rare earths at a low price?

- And the plasma cAMP regards plasma technology as the core productivity and will not easily transfer the production line to the mainland. Therefore, plasma prices will be at a disadvantage.Lost the advantage of the price, plasma will gradually fade out of sight.

- Q:What's the stability of rare earth calcium zinc stabilizer? What are the advantages?

- The dispersion and anti decomposition properties of rare earth calcium zinc stabilizer are better than that of lead salt stabilizer, and the color, brightness and firmness of the product are improved. Besides, the defects that lead salts are easy to generate sulfuration pollution are avoided.

- Q:What is the difference between a multicomponent alloy and a rare earth alloy?

- Aluminum is an alloy of aluminum and copper, magnesium and manganese. This alloy is suitable for pressing and forming. The strength and hardness of the alloy are much larger than those of general aluminum.

1. Manufacturer Overview |

|

|---|---|

| Location | Shandong,China |

| Year Established | |

| Annual Output Value | |

| Main Markets | Pakistan,Spain,Korea, Brazil |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | percent of export |

| Export Percentage | |

| No.of Employees in Trade Department | 50-100 |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steelmaking Magnesium Ferrosilicon

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 500 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords