Steel Paltfrom Type For Warehouse Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

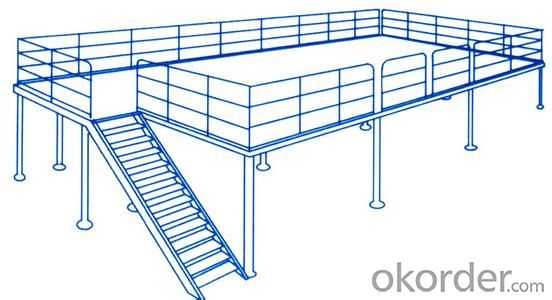

It ‘s steel platform, one type of pallet racking system, also called attic shelf or multi layer racking system.

It is suitable for limited space of warehouse and could have multi layers two or three.

Feature:

· Ladder or hydraulic lift for upstair.

· Metal floor.

· For different goods.

· Frame suppor the floor.

Images:

Specification:

Loading Capacity | 500KG/sqaure meter |

Beam Space | 3-5 meter |

Height | customized |

FAQ:

What is steel platform ?

Steel platform is used in factory for space usage, usually have 2-3 floors and have big loading capacity. Ladder is equipped for going upstairs.

How is quality guaranteed?

The production use professional technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation for project.

- Q:What's the sea cucumber logistics equipment?

- Sea cucumber contains a lot of nutrients, can strengthen the body, nourishing Yin, beauty, you can simply use "life preservative" to describe. The sea cucumber is rich in nutrition, in which some characteristics of components, namely with low cholesterol, fat content is relatively small, is a typical high protein, low fat, low cholesterol food, and is especially suitable for patients with hypertension, hyperlipidemia and coronary heart disease.

- Q:How to classify logistics facilities and equipment is more reasonable and scientific

- Logistics infrastructure refers to some of the links in the whole supply chain services and supply chain, to meet the needs of the organization and management of logistics collectively, with comprehensive or single function place or organization, including roads, railways, ports, airports, distribution center and network communication base etc..

- Q:What are the main facilities and equipment in the warehouse?

- 1, horizontal transport equipment, including a variety of vehicles, conveyor belts, belt machines, etc.;2, packaging equipment: including packaging, packaging machinery, yards, equipment and so on;3 、 vertical conveying equipment: hoist, forklift, stacker and so on;4, handling equipment: such as a large crane (gantry container cranes), ship unloading of various professional equipment (car);5 、 Safety Monitoring equipment;6 、 automatic management equipment.

- Q:How to do the warehouse logistics supervisor?

- Understand the functions of this warehouse. Although the main function of the warehouse is to store and keep the goods, the warehouses of different enterprises have different functions.

- Q:What aspects of logistics and warehousing management?

- Should meet the following requirements in the general layout of warehouse: (1) abide by the laws and regulations of various buildings and facilities planning; (2) to meet the requirements of warehouse operation smoothly, avoid repeated handling circuitous transportation; (3) ensure the storage of goods safety; (4) ensure the working safety; (5) the maximum use the warehouse area; (6) to make full use of warehouse facilities and equipment; (7) comply with the security and fire protection requirements; (8) consider warehouse expansion requirements.

- Q:What is lean storage?

- With the development of enterprises, enterprises need to increase investment in all aspects, especially in warehousing, but also in warehousing, storage facilities, handling equipment, sorting equipment, barcode technology and other aspects of investment.Application of bar code technology can effectively solve the enterprise operation efficiency is low, the inventory control is difficult, difficult to manage their problems, and can easily cope with the market change constantly.Implementation of warehouse management informationization, we must establish the only encoding for each and every variety of products, and the use of bar code printer to make barcode label on the packaging of clothing or hang in the product tag.This will not happen again, the goods can not be found, missed the opportunity to sell the situation.

- Q:Storage facilities and equipment is not perfect, what?

- In the future, warehousing centres will be reduced in number, but the number of goods at each center will increase. As a result, the distribution centers are larger on the one hand, and on the other hand, more orders are being processed daily. This means that the speed of the shipment is increased and the receipt, placement, picking and shipment are increased. This trend will put forward higher requirements for material handling systems, and will have a significant impact on forklifts and conveyor belts.

- Q:How to carry out logistics warehousing operations?

- The functions of storage in the storage function is not limited to simple, therefore, provide additional value-added services, such as additional value-added functions of circulation processing, combination packaging, labels can achieve warehouse, increase revenue and improve customer satisfaction

- Q:The differences and advantages between warehouse logistics and ocean shipping logistics

- To reduce reliance on artificial demand, especially the special storage environment to reduce the cost of human resources due to use of automation technology, automated warehouse can adapt to the needs of the dark, toxic, low temperature and other special occasions.

- Q:What are the types of logistics equipment?

- According to the equipment in the logistics activities in a considerable position, can be divided into fixed equipment and movable equipment. Fixed equipment such as railway, highway, bridge and tunnel; stations, ports, warehouses and other buildings I equipment such as train, cars, ships, mobile handling equipment.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Paltfrom Type For Warehouse Storage

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords