Stainless Steel Wire Drawing Machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

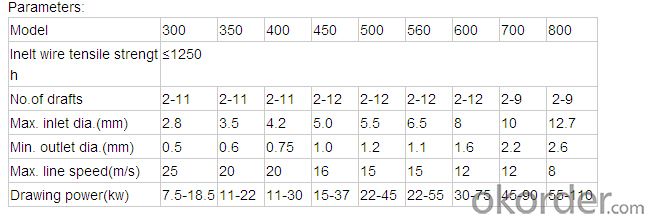

Specifications for Wire Drawing Machine

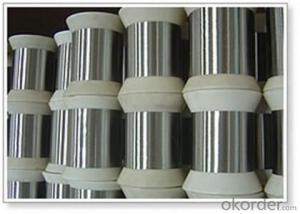

Straight Line Stainless Steel Wire Drawing Machine

1.electric parts adopt first-class brand at home and abroad.

2.PLC control.

Straight Line Stainless Steel Wire Drawing Machine

Description:

Straight Line stainless steel Wire Drawing Machine is mainly used for drawing various of metal wire from 6mm to 0.5mm , particularly suitable for drawing steel wire(high,medim,low carbon steel,stainless steel wire,prestressed wire,bead wire, rubber tube wire,spring steel wire,),welding wire(gas protection welding wire, submerged arc welding wire, flux-cored wire),alloy wire etc.

Technological process:

Pay-off---- Shell cleaning(pre-processing) ---- Wire rod pointing----(Buttering)----Drawing wire ---- Annealing ---- Take-up(spool or trunk take-up).

|

Main characteristics:

Reliability:Field bus technology was adopted to electrical control system,all digital control, electrical components are all international famous brand.Electrical control system is stable and reliable operation.

Energy saving: It adopts AC frequency regulator dragging which can reduce the impact of machine commission caused by motor start.

Security:It has multiple protection function, shield will open when the equipment high speed commission,or slow down to stop when meet other trouble.

High efficiency:It reduces the failure rate,average high working speed,greatly improve production efficiency.

Image for Wire Drawing Machine

|

| | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

| | | |

.

- Q:What is the difference between industrial cleaning equipment and general cleaning equipment?

- One: industrial high pressure cleaning machine: product positioning is machine equipment The industrial high pressure cleaning machine is designed according to the condition of industrial cleaning, the main characteristics are: high reliability, high load capacity, high safety factor. The materials used in machine manufacturing are quite elegant, including manufacturing accuracy, heat treatment of materials, testing and strength tests. The product localization of general cleaning equipment is general tool search Commercial grade washing machine is designed according to general commercial purpose, use high speed and simple structure commonly. Main features: high speed, light and low price, suitable for clean operation of general purpose of field cooperation with low workload and low pressure.

- Q:The main parameters of ultrasonic cleaning equipment

- Frequency: greater than 20KHz, which can be divided into low frequency, medium frequency, high frequency 3 segments. 2. The power density, power density = transmission power (W)/launch area (cm2) usually acuity 0.3 W/cm2, the higher the power density of the ultrasonic and cavitation effect is stronger, the faster, the better cleaning effect. But for delicate, surface finish, the high power density of long time can be used to "cavorate" the surface of the object. 3. The ultrasonic frequency, ultrasonic frequency is lower, the easier the cavitation in the liquid, the strength is big, has the stronger, is suitable for the workpiece (coarse, dirty) at the beginning of washing. High frequency of ultrasonic direction, suitable for fine cleaning. 4. Clean temperature: generally speaking, ultrasonic at 30 ℃ and 40 ℃ when cavitation effect is best. The higher the temperature, the greater the effect. Normally when actual application of ultrasonic wave, using the working temperature of 50 ℃ to 70 ℃.

- Q:How do you clean the household central air conditioner

- Household central air conditioning main cleaning filter and the house of the dirt on the condenser fin, under normal circumstances can filter down to water boiling, outdoor hoses washed clean. As for the internal cleaning of the refrigeration system, it is usually not necessary to clean the system as long as it is cleaned.

- Q:How do you clean the inside of the electric oven? Can you use a wire ball or a detergent?

- First wear latex gloves, detachable parts are removed inside the oven, such as baking, chassis, and then with a neutral detergent washing, paying special attention to oil dirties is very heavy, can use special cleaning fluid, such as the kitchen cleaner to do the key parts of decontamination. Then put an old newspaper in the door of an embedded oven and brush the broken pieces of the oven out of the oven with a small brush. Outside of the inside of the oven to heat pipe and heat pipe shield must use dry cloth to wipe gently, can't use a wet cloth, so as not to affect the heating pipe insulation, leakage phenomenon of short circuit. Except for the removable part of the oven, it is not possible to scrub clean and water with water or a wet cloth. If found the heating tube and fence are dirty, with dry cloth to wipe clean, also can not change with the rough surface such as steel wire ball, clean ball cleaning tools to wipe. If you have wire or hard particles falling into the heating tube, light barbecue an unpleasant feeling of anxious burnt flavour, or cause the entire circuit short circuit, can try to use clean force strong nylon cloth is wiped a few times more. After cleaning the heating tube, you can begin to clean the outer shell of the oven and the inside bladder. The cloth in the diluent of neutral detergent slightly wet, wipe with wet wipe the body shell, dip again after cleaning, diluent, and wring dry, into the oven inside pumice, final reoccupy clear water rinse wipe dry after dry, wipe it twice.

- Q:Is it ok to clean the car with a dry ice cleaner?

- High pressure water gun. Spray the cleaning agent for 5 minutes, start the car, then charge again. Be careful to avoid high pressure packs, electrical appliances, computer boards, and air intake.

- Q:The oil can be cleaned by the tank cleaning and the cleaning of the tank is the cleaning of the machine

- There are a lot of mechanical cleaning equipment in storage tanks, and the cleaning process is different, and the cleaning effect is different.

- Q:What should I consider? To solve the

- Cleaning equipment at present, a lot of international medical devices by using ion exchange, reverse osmosis and ion exchange group legal and reverse osmosis and EDI combination preparation of medical apparatus and instruments clean water, the water treatment equipment manufacturers aimed at the development of medical cleaning equipment market space, are put into research and development industry. According to the process of the preparation of ultra-pure water, there must be an advantage in the development of devices.

- Q:What is the pool cleaning equipment

- TR - 300 pool cleaning machine (the queen) : by motor sediment and suspended solids in the suction machine, the water through the filter to filter inside the machine, put the clean water, so as to achieve the cleaning effect. Hd5/11c water gun: applied to the outside of the building, the outside of the building, the external gun, the garage, the floor of the workshop, the kitchen, the vehicle, the pool cleaning, etc.

- Q:What are the benefits of sanitation

- It's good for the equipment and it's comfortable to watch

- Q:How often do the reverse osmosis of pure water equipment wash the search?

- Generally, under the condition of normal operation, reverse osmosis membrane may also be inorganic scale, colloid, microorganism, metal oxides, such as pollution, these substances deposited on the membrane surface to cause water purification equipment, reverse osmosis device output descent or desalination rate, differential pressure increases, and even cause unrecoverable damage to membrane, therefore, in order to restore good waterproof and desalination performance, need for chemical cleaning membrane.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Wire Drawing Machine manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords