stainless steel ; round bar steel ;steel rod

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

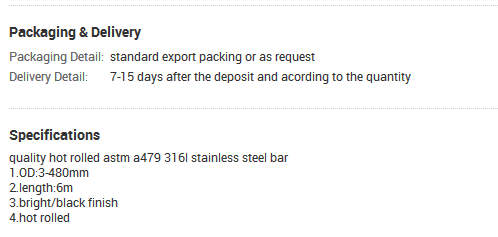

Product Description:

Stainless Steel Bar

Stainless Steel Round Bright Bar

Hot-rolled Stainless Steel Black Bar

Grades:201、202、301、302、303、304、316、316L、321 etc

Diameter (mm) | weight (kg/m) | Diameter (mm) | weight (kg/m) | Diameter (mm) | weight (kg/m) | Diameter (mm) | weight (kg/m) |

2 | 0.025 | 14 | 1.221 | 30 | 5.607 | 50 | 15.575 |

3 | 0.056 | 15 | 1.402 | 32 | 6.38 | 55 | 18.846 |

4 | 0.1 | 16 | 1.595 | 34 | 7.202 | 60 | 22.428 |

5 | 0.156 | 18 | 2.019 | 35 | 7.632 | 65 | 26.322 |

6 | 0.224 | 19 | 2.249 | 36 | 8.074 | 70 | 30.527 |

7 | 0.305 | 20 | 2.492 | 38 | 8.996 | 75 | 35.044 |

8 | 0.399 | 22 | 3.015 | 40 | 9.968 | 80 | 39.872 |

9 | 0.505 | 24 | 3.588 | 42 | 10.99 | 85 | 45.012 |

10 | 0.623 | 25 | 3.894 | 45 | 12.616 | 90 | 50.463 |

11 | 0.754 | 27 | 4.542 | 46 | 13.183 | 95 | 56.226 |

12 | 0.897 | 28 | 4.884 | 48 | 14.354 | 100 | 62.3 |

- Q:How do steel round bars contribute to sustainable construction?

- Steel round bars contribute to sustainable construction in several ways. Firstly, steel is a highly durable and long-lasting material. Steel round bars are known for their strength and resilience, which allows them to withstand heavy loads and extreme weather conditions. This durability ensures that structures built with steel round bars have a longer lifespan, reducing the need for frequent repairs or replacements. This not only saves money but also reduces the environmental impact associated with the production and disposal of construction materials. Additionally, steel is a highly recyclable material. When a structure reaches the end of its life cycle, the steel round bars can be easily and efficiently recycled. This reduces the demand for virgin steel production, which is an energy-intensive and environmentally harmful process. Recycling steel also helps to reduce waste in landfills and conserve natural resources. Moreover, steel round bars can be prefabricated off-site, which offers several environmental benefits. Prefabrication allows for greater precision and efficiency in construction, reducing material waste and energy consumption. It also minimizes noise, dust, and pollution on-site, making construction projects more sustainable and less disruptive to the surrounding environment. Furthermore, steel round bars are often used in sustainable building designs. Steel structures can be designed to maximize natural light and ventilation, reducing the need for artificial lighting and air conditioning. This improves energy efficiency and reduces greenhouse gas emissions. Steel's versatility also allows for flexible and adaptable designs, facilitating future modifications and extensions without significant demolition or waste generation. Lastly, steel round bars are commonly used in the construction of green buildings and sustainable infrastructure. These structures are designed to minimize their environmental impact throughout their life cycle, from construction to operation and eventual decommissioning. Steel's attributes, such as its recyclability, durability, and energy efficiency, make it a preferred choice in sustainable construction practices. In conclusion, steel round bars contribute to sustainable construction by offering durability, recyclability, prefabrication opportunities, energy efficiency, and versatility. By using steel in construction projects, we can reduce waste, conserve resources, minimize environmental impact, and create structures that are built to last.

- Q:Can steel round bars be used for making agricultural equipment or machinery?

- Agricultural equipment and machinery can indeed be made using steel round bars. Steel, a material known for its versatility and durability, is commonly employed in the manufacturing of various agricultural equipment and machinery. Steel round bars, specifically, are frequently utilized for the creation of essential components like shafts, axles, and rods, which are vital for the proper functioning of agricultural machinery. These round bars offer strength, stability, and resistance to wear and tear, making them well-suited for the demanding tasks within the agricultural industry. Moreover, steel is highly resistant to corrosion, a particularly crucial characteristic in agriculture where equipment is exposed to harsh environmental conditions. Overall, steel round bars are a dependable option for constructing agricultural equipment or machinery due to their mechanical properties and ability to endure the challenging conditions of agricultural operations.

- Q:What is the maximum temperature steel round bars can withstand?

- Steel round bars have varying maximum temperatures they can withstand depending on their specific grade. Nevertheless, most steel round bars generally remain structurally intact at temperatures between approximately 1000 and 1200 degrees Celsius (1832 to 2192 degrees Fahrenheit). It is worth mentioning that extended exposure to high temperatures can result in decreased strength and hardness of the steel, along with potential dimensional alterations and distortion. Moreover, the properties and behavior of steel at elevated temperatures can be influenced by factors like alloy composition, heat treatment, and the presence of other elements or impurities. If applications require steel round bars to endure exceedingly high temperatures beyond the typical range, specialized high-temperature steels like heat-resistant or creep-resistant alloys may be employed. These alloys are specifically engineered to retain their mechanical properties and structural integrity even at elevated temperatures, often reaching several thousand degrees Celsius.

- Q:What is the maximum carbon content allowed for steel round bars?

- The maximum carbon content allowed for steel round bars can vary depending on the specific grade or specification of steel being used. However, in general, most standard steel round bars have a maximum carbon content of around 0.25% to 0.30%. This level of carbon content helps to maintain a balance between strength and ductility, ensuring that the steel is both strong enough to withstand load-bearing applications and flexible enough to be easily formed or machined. It is important to note that some specialized steels or specific applications may have different maximum carbon content requirements, so it is always essential to refer to the relevant specifications or standards for accurate and specific information.

- Q:What is the difference between a forged and a peeled steel round bar?

- Both forged steel round bars and peeled steel round bars are utilized in various industries for different purposes. However, there exist notable distinctions between the two concerning their manufacturing procedures and physical attributes. To produce a forged steel round bar, a solid steel billet is heated to a high temperature and then shaped into the desired form by applying pressure. This process involves the use of machinery, such as hammers or presses, to shape the steel and create the round bar. The forging process enhances the strength and durability of the steel, making it suitable for applications that demand high strength and resistance to wear and tear. In contrast, a peeled steel round bar is manufactured using a different process called peeling or turning. During this procedure, a solid steel bar is rotated against a cutting tool, which eliminates the outer layer of the bar, resulting in a smooth and precise surface finish. Peeling eliminates any surface defects or imperfections present in the original bar, thereby enhancing its dimensional accuracy and surface quality. Regarding physical characteristics, forged steel round bars typically possess a rougher surface texture due to the nature of the forging process. This rough texture can provide improved grip or adhesion in certain applications. Additionally, forged bars often exhibit a denser and more uniform internal grain structure, contributing to their superior mechanical properties. On the other hand, peeled steel round bars exhibit a smooth and shiny surface finish as a consequence of the peeling process. This smooth surface makes peeled bars suitable for applications that prioritize aesthetic appeal or require a low coefficient of friction. However, the peeling process may result in a minor reduction in the overall diameter of the bar. In conclusion, the primary distinction between a forged and a peeled steel round bar lies in their manufacturing processes and resulting physical attributes. Forged bars are created through the application of pressure, resulting in a rougher surface texture and superior mechanical properties. Peeled bars, on the other hand, are produced by removing the outer layer of a steel bar, resulting in a smooth surface finish and improved dimensional accuracy. Ultimately, the choice between these two types of bars depends on the specific requirements of the application at hand.

- Q:How are steel round bars stored?

- Steel round bars are typically stored in a vertical position, either stacked on racks or placed in specially designed shelves or racks. These storage methods ensure that the bars are well-supported and easily accessible for transportation and use. Additionally, steel round bars are often bundled or strapped together to prevent them from rolling or becoming disorganized.

- Q:Are steel round bars suitable for use in the marine industry?

- Steel round bars are a great choice for the marine industry. They are made of strong and durable material, which makes them perfect for marine use. In the marine industry, where there are harsh environmental conditions like saltwater, waves, and corrosion, steel is an excellent option. Steel round bars have exceptional tensile strength and can withstand impact, making them suitable for various marine components such as shipbuilding, offshore structures, and marine equipment. Moreover, steel is readily available, cost-effective, and can be easily customized to meet specific requirements, making it a popular choice in the marine industry. However, it is crucial to choose the right grade of steel, like stainless steel, which has good corrosion resistance. This ensures long-term durability and performance in marine environments. It is also important to regularly maintain steel round bars in marine applications, including proper coating and protection against corrosion, to enhance their lifespan.

- Q:Can steel round bars be used for making handrails?

- Yes, steel round bars can be commonly used for making handrails due to their durability and strength.

- Q:How do I determine the strength and hardness of a steel round bar?

- In order to assess the strength and hardness of a steel round bar, various methods and tests can be employed: 1. Tensile Test: The strength of a steel bar is commonly determined through this method. It involves subjecting the bar to a tensile force until it fractures, and measuring the maximum force or load it can endure. This test provides information on the bar's ultimate tensile strength, yield strength, and elongation. 2. Hardness Test: Several techniques, such as the Rockwell, Brinell, and Vickers hardness tests, can be utilized to measure the hardness of a steel bar. These tests entail indenting the bar's surface using a standardized indenter and gauging the resulting indentation size. The obtained hardness value indicates the bar's resistance to deformation and wear. 3. Charpy Impact Test: This test gauges the toughness of a steel bar by striking it with a swinging pendulum and measuring the energy absorbed during fracture. It helps assess the bar's ability to withstand brittle fracture under conditions of impact loading. 4. Microstructural Analysis: Examining the microstructure of the steel bar through microscopic observation can offer insights into its mechanical properties. By preparing a polished and etched sample and inspecting it under a microscope, the presence of different phases, grain size, and any structural irregularities can be observed. Various microstructural features can impact the bar's strength and hardness. 5. Chemical Composition Analysis: The chemical composition of the steel bar, particularly the carbon content, significantly influences its strength and hardness. Analyzing the composition using techniques like spectroscopy or chemical analysis can provide valuable information about the bar's mechanical properties. It should be emphasized that these tests and techniques must be carried out by qualified professionals in a controlled laboratory setting to ensure accurate and reliable results. Moreover, specific standards and specifications may exist for different applications, so referring to relevant standards and guidelines can offer further guidance on determining the strength and hardness of a steel round bar.

- Q:What are the different grades of tool steel round bars?

- There are several different grades of tool steel round bars, including A2, D2, O1, S7, and H13. Each grade has its own unique properties and is suitable for specific applications in the manufacturing and machining industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

stainless steel ; round bar steel ;steel rod

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords