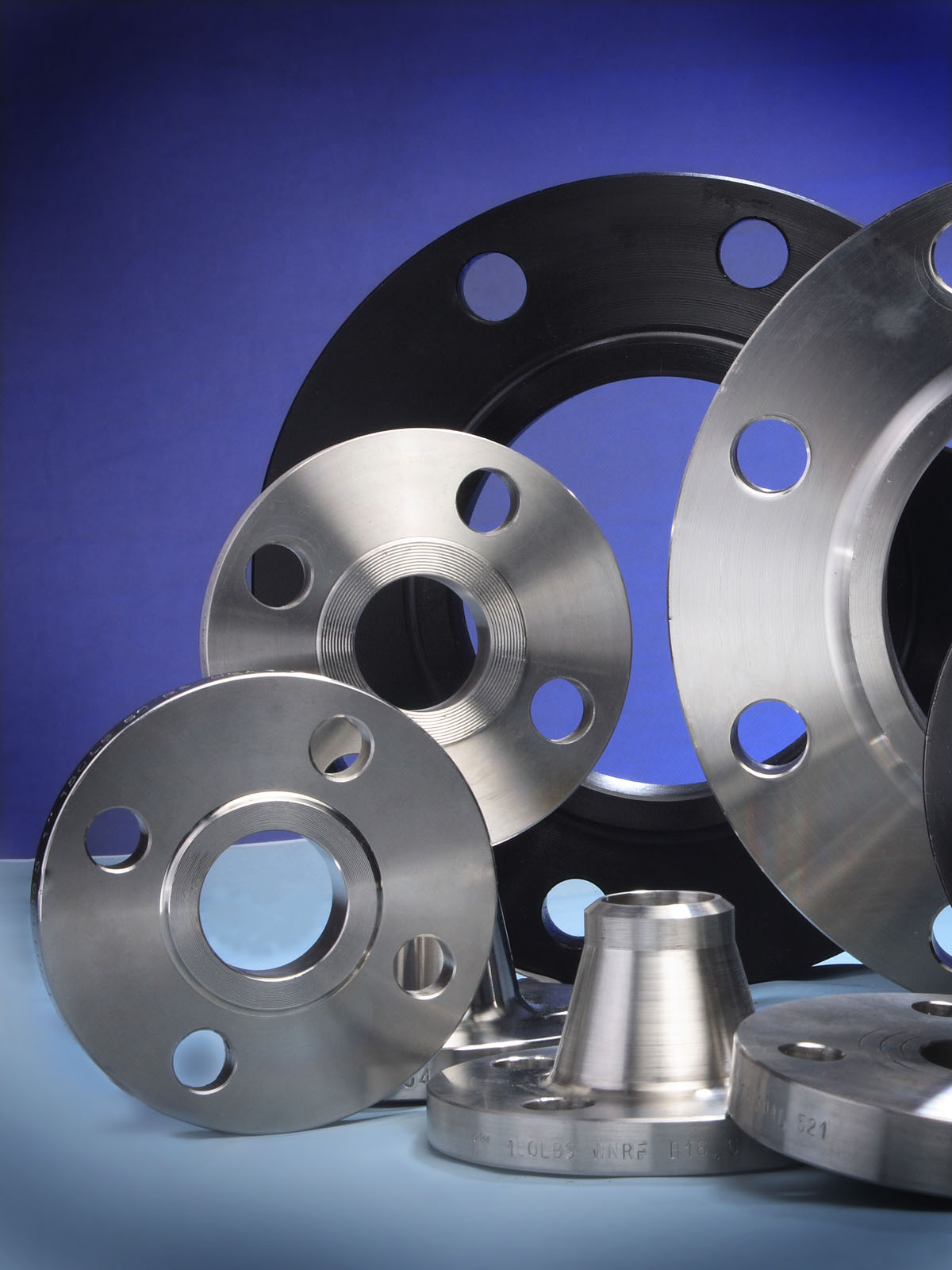

Stainless Steel Fittings TP304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Fittings

Specifications Features:

1) Carbon steel fitting and stainless steel fitting

2) Standard: ASME, ANSI, API, JIS

1. BUTT WELDED FITTING:

2. Production acc. to the standard of GB /ASTM / ASME / DIN / JIS

ASTM B 16.9 /16.11 B 16.28 JIS B 2311/2220 DIN2617/2616/2615/2391

3. Types: Elbows, seamless and welded, LR & SR ,Bend -Equal and reducing Tees,

seamless and welded - Concentric and eccentric Reducers,seamless and welded -Caps

4. Wall thickness: From Sch5 up to Sch160/STD/XS/XXS

5. Material Grades: A403,WP304, WP304L, Wp316, WP316L, A234WPB

6. Dimensions: Seamless: from 1/2' up to 24'

7. size: From 1/2" up to 72"

Outer packing:Seaworthy plywood case

|

Grade |

TP304,TP304L,TP321,TP316L,TP310S etc. |

|

connection |

welding |

|

techniques |

forged |

|

Surface finishing |

180/240/320/400 grit |

- Q:Can stainless steel flats be used in power plants?

- Yes, stainless steel flats can be used in power plants. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various applications within power plants, including structural components, piping systems, heat exchangers, and turbine parts. Its ability to withstand high temperatures, pressure, and exposure to corrosive environments makes stainless steel flats an ideal choice for power plant operations.

- Q:What are the creep properties of stainless steel flats?

- The ability of stainless steel flats to deform under stress over time at elevated temperatures is referred to as their creep properties. Creep occurs when the stainless steel is constantly or intermittently loaded, resulting in gradual plastic deformation. Stainless steel flats generally have excellent resistance to creep due to their unique microstructure and alloying elements like chromium and nickel. These elements contribute to the formation of a passive oxide layer on the metal's surface, enhancing its resistance to oxidation and creep deformation. Parameters such as creep strain, creep rate, and creep rupture strength are typically used to characterize the creep properties of stainless steel flats. Creep strain represents the amount of deformation that occurs within a specific time period, while creep rate measures the rate of deformation. Creep rupture strength is the maximum stress that the stainless steel can endure before fracture occurs under creep conditions. The creep properties of stainless steel flats are influenced by factors like temperature, stress level, and exposure time. Higher temperatures and stress levels tend to accelerate creep deformation, while longer exposure times increase the likelihood of creep failure. Therefore, it is crucial to consider these factors when designing and utilizing stainless steel flats in applications where creep resistance is crucial. In conclusion, stainless steel flats possess favorable creep properties, making them suitable for applications requiring high temperatures and long-term structural integrity. However, it is essential to assess the specific requirements and operating conditions to ensure optimal performance and durability of the stainless steel flats.

- Q:Are stainless steel flats suitable for food processing applications?

- Stainless steel flats are an excellent choice for food processing applications, as they possess a multitude of desirable qualities. Due to its exceptional corrosion resistance, high strength, and durability, stainless steel is widely utilized in the food industry. Its resistance to staining guarantees a clean and hygienic food processing environment. Moreover, stainless steel flats are effortlessly cleaned and maintained, making them perfect for applications that necessitate frequent washdowns and sanitization. Additionally, stainless steel is non-reactive and does not release any harmful chemicals into the food, thus ensuring the safety and quality of the processed products. In conclusion, when it comes to food processing, stainless steel flats are a dependable and preferred option.

- Q:What is the fatigue strength of stainless steel flats?

- The fatigue strength of stainless steel flats refers to their ability to withstand repeated loading and unloading cycles without experiencing failure or fatigue. The exact fatigue strength of stainless steel flats can vary depending on factors such as the grade of stainless steel, surface finish, heat treatment, and the specific loading conditions. It is typically determined through fatigue testing, where the number of cycles a sample can withstand before failure is measured.

- Q:What is stainless steel flat?

- A specific type of stainless steel product known as stainless steel flat is sought after for its flat shape. It finds widespread use in different industries and applications that require a smooth and flat surface, including construction, automotive, kitchenware, and manufacturing. The production of stainless steel flat involves hot rolling or cold rolling stainless steel sheets or coils, resulting in a thin and flat product with even thickness and smooth edges. Its remarkable resistance to corrosion makes it particularly suitable for environments with frequent exposure to moisture or chemicals. Stainless steel flat is renowned for its strength, durability, and versatility, which contribute to its popularity across various industries.

- Q:What are the different types of stainless steel flats used in the oil and gas industry?

- In the oil and gas industry, stainless steel flats are widely used due to their excellent corrosion resistance and high strength characteristics. There are several different types of stainless steel flats that are commonly employed in this industry, each offering specific advantages depending on the application. 1. Austenitic Stainless Steel: This type of stainless steel, particularly grades 304 and 316, is highly resistant to corrosion and oxidation. It is widely used in oil and gas applications that involve exposure to corrosive environments, such as offshore platforms or pipelines. 2. Duplex Stainless Steel: Duplex stainless steel combines the desirable properties of both austenitic and ferritic stainless steel. It offers excellent resistance to stress corrosion cracking, making it suitable for applications where high strength and corrosion resistance are required, such as subsea equipment or oil refinery components. 3. Martensitic Stainless Steel: Martensitic stainless steel, such as grade 410 or 420, is known for its high strength and hardness. It is often used in applications that require resistance to wear, such as valves, pumps, or drilling tools. 4. Precipitation-Hardening Stainless Steel: This type of stainless steel, also known as PH stainless steel, is heat treatable to achieve high strength while maintaining good corrosion resistance. It finds applications in downhole tools, wellhead components, or other equipment that requires a combination of strength and corrosion resistance. 5. Super Duplex Stainless Steel: Super duplex stainless steel offers superior corrosion resistance compared to standard duplex grades. It is commonly used in aggressive environments, such as seawater systems, offshore platforms, or subsea pipelines, where resistance to pitting, crevice corrosion, and chloride-induced stress corrosion cracking is crucial. Overall, the choice of stainless steel flats in the oil and gas industry depends on factors like the specific application, operational conditions, and environmental factors involved. Each type of stainless steel offers unique properties that make it suitable for various oil and gas equipment, ensuring durability and reliability in demanding operating environments.

- Q:How do stainless steel flats compare to carbon steel flats?

- Stainless steel flats have superior corrosion resistance compared to carbon steel flats, making them highly suitable for applications in humid or corrosive environments. However, carbon steel flats offer higher strength and hardness, making them more suitable for heavy-duty applications that require durability and load-bearing capacity. The choice between stainless steel and carbon steel flats depends on the specific requirements of the application.

- Q:How do I calculate the moment of inertia for a stainless steel flat with holes?

- To calculate the moment of inertia for a stainless steel flat with holes, you need to consider the individual moments of inertia for each component of the object. First, determine the moment of inertia for the solid stainless steel flat. The moment of inertia for a rectangular plate can be calculated using the formula I = (1/12) * m * (h^2 + b^2), where m is the mass of the plate, h is the height, and b is the width. Next, calculate the moment of inertia for each hole in the flat. This can be done using the formula I = (1/4) * m * r^2, where m is the mass of the hole and r is the radius of the hole. Once you have determined the moment of inertia for each component, you can sum them together to get the total moment of inertia for the stainless steel flat. Keep in mind that if the holes are symmetrically distributed, you may be able to simplify the calculation by using the parallel axis theorem, which states that the moment of inertia of a component about an axis parallel to and a distance 'd' away from the component's centroid is equal to the sum of the moment of inertia about the centroid and the product of the component's mass and the square of the distance 'd'. It is important to note that the accuracy of this calculation depends on the complexity and distribution of the holes in the stainless steel flat. For irregular shapes and non-uniform hole distributions, more advanced mathematical methods, such as numerical integration or computer simulations, may be necessary to obtain an accurate moment of inertia value.

- Q:What are the dimensions tolerance for stainless steel flats?

- The dimensions tolerance of stainless steel flats can differ depending on the particular grade and manufacturing process of the stainless steel. Typically, industry standards like ASTM or ISO establish the dimensions tolerance for stainless steel flats. These standards offer guidelines for the acceptable range of dimensions and tolerances for stainless steel flats. The dimensions tolerance usually encompasses parameters such as thickness, width, and length. For instance, the acceptable thickness tolerance might be defined as a range of ±0.005 inches or ±0.13 millimeters. Apart from the overall dimensions, the dimensions tolerance may also specify the surface finish, straightness, and flatness. The surface finish refers to the smoothness and texture of the flat surface, while straightness and flatness pertain to the absence of curvature or warping. It's worth noting that the dimensions tolerance for stainless steel flats can vary depending on the intended application and specific customer requirements. Therefore, it is recommended to consult the applicable industry standards or collaborate with a reputable manufacturer or supplier to ensure compliance with the desired dimensions tolerance for stainless steel flats.

- Q:Can stainless steel flats be used in the production of conveyor systems?

- Stainless steel flats have the capability to be utilized in the manufacturing of conveyor systems. The material known as stainless steel possesses exceptional durability and resistance to corrosion, thus rendering it an excellent option for conveyor systems that may come in contact with hostile environments or substances that cause corrosion. Stainless steel flats contribute to the smooth movement of materials by offering a frictionless surface, ultimately enhancing the efficiency of conveyor operations. Furthermore, stainless steel flats exhibit tolerance to high temperatures, making them well-suited for applications that demand heat resistance. In summary, stainless steel flats provide conveyor system production with qualities of strength, longevity, and dependability, consequently making them a fitting choice.

1. Manufacturer Overview |

|

|---|---|

| Location | Anhui,China |

| Year Established | 2003 |

| Annual Output Value | Above US$16 Million |

| Main Markets | South Korea;Japan; Europe;ASEAN;India |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 70% |

| No.of Employees in Trade Department | 160 People |

| Language Spoken: | English;Chinese;Japanese;Korea |

| b)Factory Information | |

| Factory Size: | Above 300,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Stainless Steel Fittings TP304

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 10000 Pieces Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords