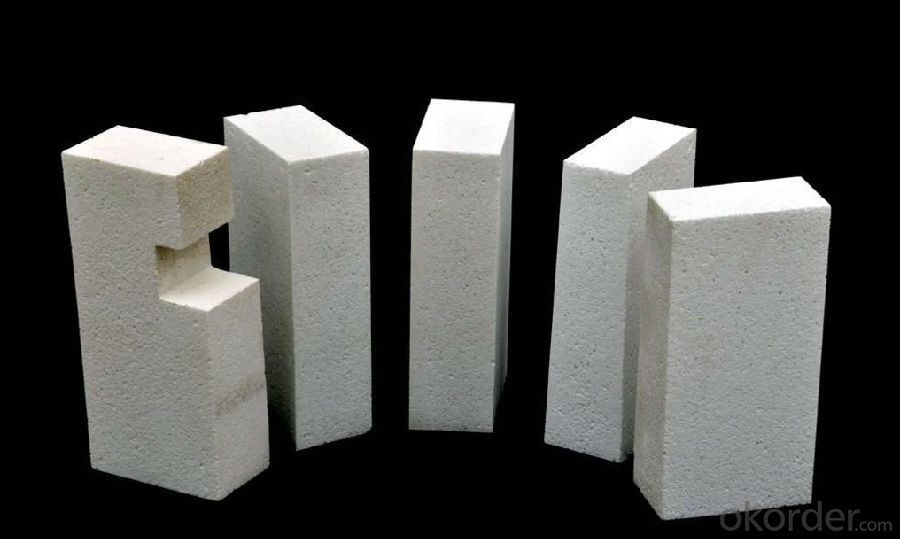

Sintered Micropore Alumina-Carbon Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1 Small average pore size;

2 High thermal conductivity;

3 Low air permeability;

4 Good infiltrate and corrosion resistant.

Sintered microporous alumina-carbon bricks

1.Row material :

high quality alumina clinker ,corundum

2.Feature :

Small average pore size;

High thermal conductivity;

Low air permeability;

Good infiltrate and corrosion resistant.

3.Application: Carbon-based Refractories for iron making .

4.Packing: are packed in carton, and put carton on wooden pallet, wrapped with plastic film outside.

5.Trail order:10tons

6.Capability:200000tons per year

7.Terms of payment:L/C TT D/A D/P

TABLE1

| NO. | ST-2-2 |

| Al2O3,% | ≥65 |

| C,% | ≥11 |

| B.D. ,g/cm3 | ≥2.85 |

| A.P. ,% | ≤16 |

| C.C.S. ,MPa | ≥70 |

Thermal conductivity /W· (m·K)-1 0-800C | ≥13 |

| Average pore size um | ≤0.5 |

| Features | Small average pore size High thermal conductivity Low air permeability Good infiltrate and corrosion resistant |

- Q:Expansion ratio of lightweight corundum refractory bricks

- Now with the production of lightweight foam corundum brick, basically still meters with molding casting, moulding after together with die in the drying room drying in 60~70 C 4 days of release, then the appropriate drying, finally after 1300 and 1550 C firing, the total burning time: 50~60h. Light corundum brick after firing is usually not the size and shape of accurate, so that products after the kiln to mechanical or manual cutting, can be made into a density of 0.8 - 1.3g/cm3, 4MPa compressive strength and porosity, the thermal conductivity of 70%~80% 0.17W/ (M - K), light-weight corundum brick use temperature of 1500~1700 DEG C.

- Q:What's the jade stove for?

- Is it a furnace made of corundum or a furnace for smelting corundum?Corundum brick stove is commonly used as a refractory material sintering furnace, can be fired refractoriness in refractories, below 1700 degrees such as brick, corundum brick, brick, alumina hollow ball and so on

- Q:What equipment is used for producing diamond blanks? How much is the investment?

- You'll have to invest about about one million if you want an electric furnace. A power distribution room is easiest to approach one hundred thousand. Electric furnaces, power distribution cabinets and transformers must be around one hundred and ten thousand.

- Q:What are the advantages of refractories?

- Special refractories are new inorganic non-metallic materials developed on the basis of traditional ceramics and refractory materials. For example, AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Often used insulation refractories are diatomite products, asbestos products, insulation panels and so on

- Q:What is the blast furnace ceramic cup called by the refractory factory?

- The refractory bricks, which are suitable for blast furnace conditions, are vitrified by high temperature sintering. They are like a huge cup, so they are called ceramic cups. The name was taken by the French, and the technology was handed down from france!

- Q:What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum brick has a strong resistance to glass liquid corrosion!It is better to fuse the furnace with fused zirconia corundum bricks.Fused zirconia corundum brick, regardless of the size of the furnace, the use of small hundreds of kilograms can be used, depending on the design of the kiln!

- Q:What kind of refractory material will be used in the glass kiln?

- It has the best resistance to high temperature E glass corrosion, its erosion basically does not cause pollution to the glass liquid, so it has become the first choice of E glass unit refractory bricks.Dense chromium oxide is formed by isostatic pressing. Its density is very high. The main technical indexes include Cr2O3 content >94%, porosity <15%, volume density >4.24g/cm3, and erosion loss only 1/10 of compact zirconia brick. Used in the E glass furnace unit kiln, directly contact high temperature molten glass melt, wall, melting parts, high temperature parts, pool bottom, main channel, pool wall and pool bottom, transition channel, pool wall, etc..

- Q:What kind of fused corundum corundum brick should be used for each part of the glass furnace?

- In addition to AZS33# and AZS same co crystallization in vitro, 36#AZS due to the increase of chain like zirconia brick more crystals, while the glass phase content is low, so 36# AZS corrosion resistance has been further enhanced, so is suitable for the rapid flow of molten glass or high temperature region.AZS36 s is an excellent product in the AZS series. It has high resistance to glass liquid erosion and low pollution. It is usually used in the key parts of the glass furnace, such as the pool wall near the hot spot.

- Q:Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q:What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Casting, casting mouth often appear shrinkage, brick porosity more, the density is lower, so in the brick wall of glass melting, the shrinkage in the kiln direction, if the nozzle outward, when the brick to erosion is very thin, can cause leakage of liquid glass accident. When the flame space is used in the upper part of the bath furnace, the service life is long, and the glass liquid problem can not happen, so the casting mouth is used outwards, and the service life is prolonged.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Sintered Micropore Alumina-Carbon Brick CNBM Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords