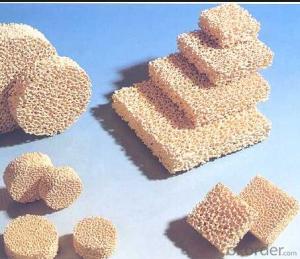

Silicon Carbide Foam Ceramic Filter for Iron or Iron Alloy Casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Description of ceramic foam filter

Characterized by high porosity,stability and excellent resistance to thermal attack

Compared with traditional filtering materials,the ceramic foam filter has obvious advantages:

2. Functions of ceramic foam filter

1). Thermal and chemical stability in high temperature,avoiding the chemical reaction with the filtered molten metal;

2). High porosity and good mechanical strength in high temperature due to its pure ceramic composite;

3). Low head loss,easy operation,energy-saving;

4). Making metal liquid flowing at stable speed and avoiding the sputtering and backset,thus increasing the surface quality of the cast part,preventing the pore disfigurement and finally lower down the unqualified rate;

5). Various sizes,shapes,apertures are available for kinds of foundry technique.

3.Physical and chemical properties

Main Performance Index:

Item | Carborundum (SiC) |

| pore density PPI | 10-40 |

| porosity (%) | 80-90 |

| refractoriness (°C) | 1500 |

| bending strength (Mpa) | 0.8 |

| compression strength (Mpa) | 1.0 |

| thermal shock resistance (times @ 1100°C) | 6 |

| applying for alloys | Cast Iron |

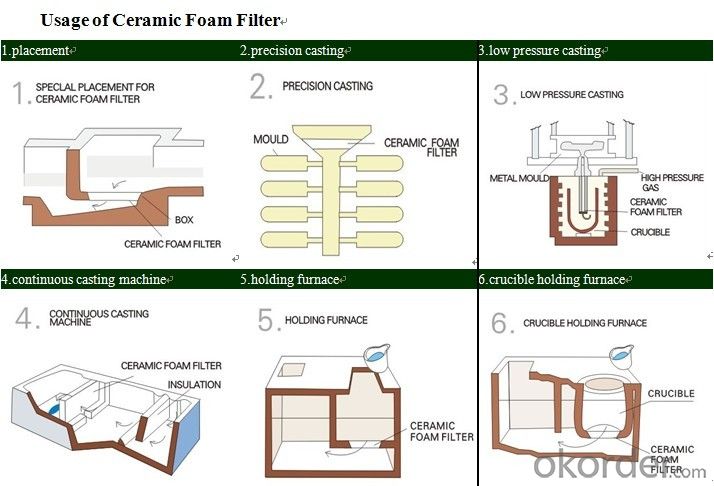

4.Usage of ceramic foam filter

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What about the leakage of the ceramic filter static and dynamic sealing points?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor. Other questions about ceramic filter, welcome to chat with me or look at my head

- Q:What's the acid of the ceramic filter plate?

- Ceramic filter boards tend to clog and acid washing is used to dissolve and dredge blockages in their pores.

- Q:Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q:Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q:Excuse me, what's the reason that all ceramic filters do not attract ore?

- After the joint cleaning, 0~2 hours of suction effect may be good, 2~4 may drop slightly, 4 hours later will become worse and worse, or even suck. This case should first check the backwash water pressure (instantaneous maximum pressure should not be less than 0.08MPa) is to meet the requirements, should also advance down (to ensure normal and ultrasonic cleaning combined with nitric acid dosage sufficient) and prolong the cleaning time.

- Q:The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect is poor, I hope to help you:

- Q:Does the ceramic factory use hydrochloric acid?

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q:Beneficiation ceramic filter no problem, the technical parameters are normal, but filter out the concentrate water suddenly excessive, what is the reason?

- First, the fineness of the material, resulting in the filter board filter cake moistureTwo, the vacuum can not reach, in the circumstances, whether the vacuum pipe leak

- Q:The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q:How should the static and dynamic sealing points of the ceramic filter be leaking?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Silicon Carbide Foam Ceramic Filter for Iron or Iron Alloy Casting

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords