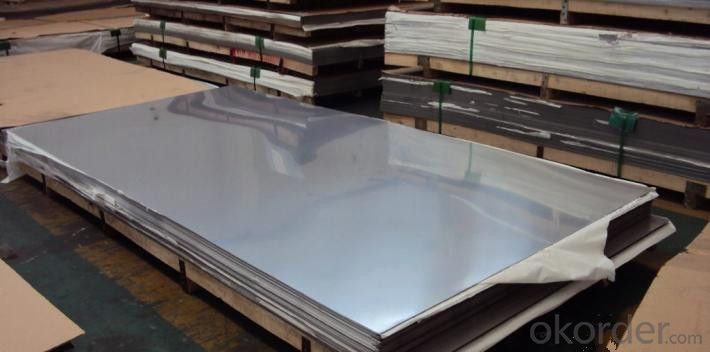

selling manufacturers stainless steel china 304 316 316l

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Best selling manufacturers stainless steel china 304 316 316l square pipe

All the materials are up to standard of GB, ROHS, SVCH.

We also accept the order of random length and other material's stainless steel pipes.

Our pipes are attractive and durable, that's the reason why we are the preferred supplier of Furniture, Handles, Sanitary Ware, and Medical Devices.

Product Details of Stainless Steel Pipe:

| Name | stainless tube |

| Standard | ASTM A554,A249,A269,A270,A312 |

| Material Grade | 201,202,304,316,316L,430 |

| Main Material | 201: Ni 0.8%~1%,202: Ni 3.5%~4.5%,304: Ni 8%,Cr 18%,316: Ni 10%,Cr 18%,316L: Ni 10%~14%,430: Cr 16%~18% |

| Outer Diameter | 8mm-76.2mm |

| Thickness | 0.5mm-1.5mm |

| Length | 6m or according to customers's request |

| Tolerance | a)Outer Diameter :+/- 0.1mm b) Thickness:+/- 0.02mm c) Length:+/- 5mm |

| Surface | 180G,240G,320G Hairline,400G,600G Mirror finish |

| Application | handrail,railing,staircase,weldmesh screen,door,window,balcony,fence,bench,furniture,ect. |

| Test | Squash test,extended test,water pressure teat,crystal rot test,heat treatment,NDT |

Know more about trade...

Payment term: 1. 30% T/T in advance, and the balance against B/L copy

2. 100% irrevocable LC at sight.

Shipment date: Within 15-20 days after advance payment or receipt of LC

Trade term: 1. FOB Shanghai port, China.

2. CIF Discharging port

Guarantee& Service: Mill Test Certificate is supplied with shipment, and Third Part Inspection is acceptable.

Packing: standard export packing (plastic package to prevent water or plywood case to strengthen package)

- Q:What is the weight of a standard stainless steel bar?

- The weight of a standard stainless steel bar can vary depending on its length, diameter, and specific grade of stainless steel.

- Q:Are stainless steel bars suitable for the production of gears?

- Yes, stainless steel bars are suitable for the production of gears. Stainless steel offers excellent corrosion resistance, high strength, and good hardness, making it an ideal material for gears that are exposed to harsh environments or require high durability. Stainless steel gears also have low friction and wear properties, ensuring smooth operation and long-lasting performance. Additionally, stainless steel can be easily machined and formed into complex gear shapes, making it a versatile choice for gear production. Overall, stainless steel bars are a reliable and popular material for the manufacturing of gears in various industries such as automotive, aerospace, and machinery.

- Q:Can stainless steel bars be used in the manufacturing of reactor vessels?

- Reactor vessels can be manufactured using stainless steel bars, which are a type of alloy containing iron, chromium, and other elements. This alloy offers exceptional resistance to corrosion, making it an excellent choice for applications where the vessel needs to endure harsh conditions such as high temperatures and corrosive environments. The use of stainless steel bars in reactor vessel manufacturing provides several advantages. Firstly, these bars possess high strength and durability, enabling the vessel to withstand internal pressure and external forces encountered during operation. Secondly, stainless steel exhibits remarkable resistance to corrosion, which is vital for reactor vessels that frequently come into contact with corrosive substances or high-temperature chemicals. This corrosion resistance contributes to a prolonged lifespan and ensures the vessel's safe and reliable operation. Moreover, stainless steel bars can be easily fabricated and welded, allowing for the production of reactor vessels in various shapes and sizes. Additionally, they possess good heat resistance properties, which are particularly important for reactor vessels operating at high temperatures. In conclusion, stainless steel bars are an appropriate choice for manufacturing reactor vessels due to their strength, corrosion resistance, and ability to withstand harsh operating conditions.

- Q:What is the difference between stainless steel bars and stainless steel rods?

- Stainless steel bars and stainless steel rods are similar in many ways, but there are a few key differences between the two. Firstly, the shape is the most noticeable difference. Stainless steel bars are typically long, straight, and rectangular in shape, resembling a bar or a beam. They usually have a uniform width and thickness throughout their length. On the other hand, stainless steel rods are cylindrical in shape and have a consistent diameter throughout their length. Another difference is the applications they are commonly used for. Stainless steel bars are often used in construction, engineering, and industrial projects where strength and durability are important. They are commonly used as structural supports, for making frames, or as components in machinery. On the other hand, stainless steel rods are frequently used in applications that require precision and tight tolerances. They are commonly used in the manufacturing of screws, bolts, valves, and other small components. In terms of availability and manufacturing processes, stainless steel bars are usually produced in larger sizes and lengths, while stainless steel rods are available in smaller diameters and lengths. The manufacturing process for both involves hot rolling or cold drawing, but rods are usually cold drawn to achieve their precise dimensions. Lastly, the cost can also differ between stainless steel bars and rods. Due to their larger size and higher weight, stainless steel bars are generally more expensive than rods. The price difference can also be influenced by the specific alloy and grade of stainless steel used. In summary, the main differences between stainless steel bars and stainless steel rods lie in their shape, applications, availability, manufacturing processes, and cost. While bars are typically rectangular and used in construction and industrial projects, rods are cylindrical and commonly used for precision components.

- Q:Are stainless steel bars suitable for guitar strings?

- Stainless steel bars do not make suitable guitar strings, as they lack the necessary flexibility and hardness. Although stainless steel is known for its durability and resistance to corrosion, it does not meet the requirements for guitar strings. To achieve the desired sound and feel while playing, guitar strings must have a certain level of flexibility. While stainless steel strings are often chosen for their bright and aggressive tone, they are usually wrapped around a core made of a more flexible material, like nickel or steel. If stainless steel bars were used as guitar strings, the playing experience would be harsh and uncomfortable, and there is also a risk of damaging the instrument.

- Q:What are the weight calculations for stainless steel bars?

- Determining the weight of stainless steel bars is possible through a simple formula. To calculate the weight of a stainless steel bar, one must multiply the bar's cross-sectional area by its length and the density of stainless steel. To determine the cross-sectional area of a stainless steel bar, knowledge of the bar's shape is necessary. Common shapes include round, square, hexagonal, or flat bars. Each shape has its own formula for calculating the cross-sectional area. In the case of a round bar, the cross-sectional area can be found using the formula: Area = π * (diameter/2)^2 For a square bar, the cross-sectional area can be determined using the formula: Area = side length^2 A hexagonal bar's cross-sectional area can be calculated with the formula: Area = (3√3/2) * side length^2 In the case of a flat bar, the cross-sectional area is obtained by multiplying the width and thickness. Once the cross-sectional area is determined, it can be multiplied by the length of the bar and the density of stainless steel to obtain the bar's weight. The density of stainless steel varies depending on its grade, but a commonly used value is approximately 7.9 g/cm^3. Weight = Cross-sectional area * Length * Density It is important to note that these calculations provide an approximate weight and may slightly vary due to manufacturing tolerances. For accurate weight information on specific stainless steel bars, it is recommended to consult the manufacturer or supplier.

- Q:Can stainless steel bars be used in construction equipment production?

- Certainly, construction equipment production can indeed utilize stainless steel bars. Stainless steel, being a versatile and resilient material, provides numerous advantages for construction equipment. Its exceptional resistance to corrosion is especially vital for outdoor equipment exposed to harsh weather conditions and moisture. Moreover, stainless steel possesses remarkable strength and toughness properties, rendering it suitable for heavy-duty machinery and equipment that necessitate sturdiness and dependability. Furthermore, stainless steel bars can be readily fabricated and welded to meet precise design specifications, thereby enabling flexibility in construction equipment production.

- Q:Can stainless steel bars be plated with gold or other metals?

- Yes, stainless steel bars can be plated with gold or other metals through a process called electroplating.

- Q:What are the applications of stainless steel bars in the semiconductor industry?

- Stainless steel bars find numerous applications in the semiconductor industry due to their exceptional characteristics and properties. The semiconductor industry requires materials that can withstand demanding operational conditions and maintain high levels of cleanliness. Here are some key applications of stainless steel bars in the semiconductor industry: 1. Wafer fabrication: Stainless steel bars are used in the production of semiconductor wafers. They provide a stable and reliable platform for the fabrication process. Stainless steel's resistance to corrosion and high temperatures ensures the integrity and quality of the wafers during processing. 2. Vacuum systems: Stainless steel bars are utilized in vacuum systems within semiconductor manufacturing equipment. These bars are often used to construct chambers, flanges, and fittings that are exposed to high vacuum conditions. Stainless steel's low outgassing properties and high strength make it an ideal material for maintaining a clean and controlled vacuum environment. 3. Cleanroom equipment: Stainless steel bars are commonly employed in the construction of cleanroom equipment such as workbenches, storage racks, and shelves. The material's smooth surface prevents particle accumulation, ensuring the cleanliness of the environment, which is critical in semiconductor manufacturing. 4. Chemical handling: Stainless steel bars are resistant to a wide range of chemicals, making them suitable for handling various corrosive substances used in semiconductor fabrication processes. They are often used in the construction of chemical delivery systems and storage tanks, ensuring the safety and integrity of the chemicals. 5. Electroplating and etching: Stainless steel bars are utilized as anodes or cathodes in electroplating and etching processes. Their excellent conductivity and resistance to chemical reactions make them an ideal choice for these applications. 6. Heating elements: Stainless steel bars with high-temperature resistance are employed as heating elements in semiconductor manufacturing equipment. These bars efficiently transfer heat to specific components or processes, ensuring precise temperature control during various stages of semiconductor fabrication. In summary, stainless steel bars play a crucial role in the semiconductor industry, providing a durable, clean, and versatile material for various applications. Their resistance to corrosion, high temperatures, and chemicals make them an essential component in the manufacturing processes of semiconductors, ensuring consistent quality and reliability.

- Q:Can stainless steel bars be used in the power generation aftermarket?

- Yes, stainless steel bars can be used in the power generation aftermarket. Stainless steel is known for its high strength, corrosion resistance, and durability, making it an excellent choice for various applications in the power generation industry. Stainless steel bars can be used in the construction of power plants, turbines, generators, and other equipment. They can withstand high temperatures, pressure, and harsh operating environments, ensuring reliable performance and longevity. Additionally, stainless steel bars can resist corrosion caused by chemicals, moisture, and gases, making them suitable for both indoor and outdoor power generation facilities. Overall, stainless steel bars are a reliable and cost-effective solution for the power generation aftermarket.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

selling manufacturers stainless steel china 304 316 316l

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords