Roofing Sheets/Sunglasses Polycarbonate/ Bed Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

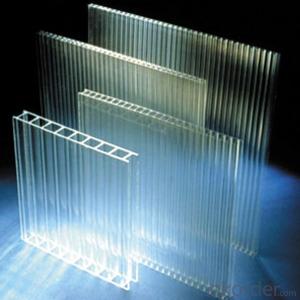

Product specifications

Item Name | polycarbonate solid sheet | Specific gravity | 1.25 |

Material | polycarbonate | Application Temperature | -40 °C ~+120 °C |

regular Size | 1220*2440mm | Impact Strength | 850J/m |

regular Thickness | 1-15mm | Light transmission | 88% |

Color | transparent/clear | Heat Conductivity | 2.3-3.9 W/ m2°C |

Application scope of Polycarbonate solid sheet

1. roofing for swimming pool, shopping malls, commercial streets

2. sunshade for stadiums and bus stops, gazebo, open air carport

2. lighting canopy for corridors, passages and subway entries

3. flashing for bank ATMs, telephone box, gateways, garages

4. sound and heat insulation wall for expressways and houses

5. instead of glass, decoration door, curtain wall

6. sound-proof material for partitions

7. unbreakable material for glazing widows, roof glazing.

8. lighting of modern villa, rainproof lighting shed of underground garage entryway

Size of products

Thickness(mm) | 8mm to 30mm |

Length(mm) | No limited |

Width(mm) | Within 2100mm |

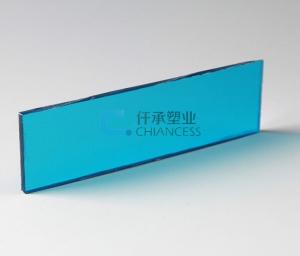

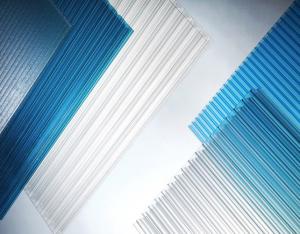

Color | Clear Opal Green Blue Bronze lake Blue and so on |

Features:

1) Light transmission: Up to88%

2) Impact resistance: 80 times that of glass, 15 times that of acrylic sheeting

3) Temperature resistance range: -40 ~ 120°, C

4) Light weight: Only 1/12 of the weight of glass of the same thickness

5) Ultraviolet resistance: With UV protective layer

6) Flame resistance: Rated class B1

7) Sound and heat proof

Product Pictures

- Q:PC Nai Liban and Sunshine board Which domestic manufacturers of the best products?

- Can afford to do a good product price, and now the technology has been very mature technology, and only look at customer requirements.

- Q:What is the difference between sun panels and lighting panels?

- Material composition description Xining PC sun panels are made of polycarbonate on the surface of a layer of 50um UV UV layer, hollow structure extrusion molding of high-performance lighting materials. Is the most excellent performance of engineering plastics, which has a light, flame retardant, high impact strength, high transmittance, high stability, easy to bend and other characteristics. And is an energy-saving, environmentally friendly materials. Is the preferred material for making lighting materials. FRP lighting board is glass fiber reinforced polyester (FRP lighting board), commonly known as FRP, also known as transparent tile, which mainly by the film, unsaturated resin and glass fiber composition. Frp main material is unsaturated resin, its high strength, flammable, the resin itself is easy to decompose above 50 ℃, poor stability. Resin is chemically synthesized, using styrene solvent, toxic.

- Q:PE sun panels and PC sun panels are different

- Different materials, PC is environmentally friendly, PC temperature, PE is not temperature

- Q:PC sun panels and color steel plate how to bond

- The use of sealant at the junction, with self-tapping screws fixed on the purlins. Transparent sun panels and insulation color plates are two different roofs. The sun panels are mainly made of PC / PET / PMMA / PP. English is sunlight, referred to as hollow board, pc sun panels to polycarbonate as the main raw material manufacturing. Sunshine board in the mid-80s into the building materials quickly. Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate. Color steel plate is divided into veneer, Caigang composite board, floor board and so on. Widely used in large public buildings, public buildings, activities board room, and integrated housing walls and roofs.

- Q:What can I do with my own sunshine board?

- PC sunshine board product range 1, office buildings, department stores, hotels, villas, schools, hospitals, sports venues, entertainment centers and public facilities of the lighting ceiling 2, the highway highway viaduct noise barriers 3, agricultural greenhouse, flower greenhouse and indoor pool of the sky 4, subway entrance, station, parking lot, shopping malls, pavilions, restrooms, corridors and other canopy 5, bank anti-theft counters, jewelry store anti-theft window, police explosion shield 6, advertising light boxes, bus station panels, advertising display cards 7, office, home indoor partition, pedestrian access, fence, balcony, shower and so on

- Q:What are the differences between plastic endurance boards and sun panels?

- Category: PC board is generally single and double board, in addition to multi-layer board, wave plate, film.

- Q:What is the difference between sun panels and plexiglass?

- Plexiglass is PMMA polymethyl methacrylate material, commonly known as acrylic. Transmittance of 92%. ??? Not spontaneous combustion but is flammable, do not have self-extinguishing. ??? The average hardness of the Rockwell hardness of about 8,9 degrees. ??? Heat resistance is not high, continuous use temperature exceeds 90 ℃ will heat deformation. ??? Cold resistance is also poor, brittle temperature of about 9.2 ℃.

- Q:What is the difference between a hollow board and a sunboard?

- The material selected for the panel should be FRP, and the selection material for the sun board is PC. The lighting board is fixed with aluminum fastener, and the corrugated board is fixed with a light plate and a self-tapping screw. The position of the lighting plate is generally set in the middle.

- Q:Lighting board and sunshine board which is good?

- The panels are made of fiberglass, and the sun panels are made of polycarbonate. Each have their own strengths and weaknesses, see your use. Sun panels used in building lighting, greenhouse shed shed more use. Low-grade will not say, high-end sunshine board can be used for more than a decade is no problem, manufacturers generally guarantee ten years! Sun plate is not strong acid and strong base this is true!

- Q:How to correctly identify the quality of pc sunshine board and pc durability plate method

- Look at the product surface. Protective film paste flat, no shedding. Indicating that manufacturers of product production, sales attention. Of course, some bag companies, small companies pay attention to packaging, because this customer is like moon cakes, in the use, the best choice for the strength of the old company

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Roofing Sheets/Sunglasses Polycarbonate/ Bed Sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords