Recarburizer low S low N carbon additive carbon riser

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Carbon Raiser:

- F.C 90-95%

- Low sulfur

- ISO 9001

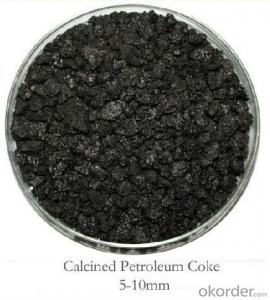

- Calcined petroleum coke

FC 90-95-99% carbon raiser for steelmaking/Calcined anthracite / graphite based / petroleum coke recarburizer

Recarburizer carbon rasier points steelmaking recarburizer (People's Republic of China ferrous metallurgy industry standards, YB / T 192-2001 steelmaking recarburizer) and cast iron with carbon agent, and other materials are also useful to add carbon rasier such as brake pads with additives, as friction materials. carbon rasier belong plus steel, iron by carbon materials. carbon rasier quality is essential for the production of high-quality steel auxiliary additives.

Carbon rasier there are a variety of raw materials, production processes are different, there are wood carbons, carbon-based coal, coke, graphite, etc., of which there are many small species under various categories. High quality carbon agent generally refers to after graphitized carbon agent under high temperature conditions, the arrangement of carbon atoms in graphite morphology was, so called graphitization. Graphitization can reduce the content of impurities recarburiser improve recarburizer carbon content and reduce sulfur content.

Recarburizer Features:

- Medium particle size, porosity, large, absorption speed.

- Using petroleum coke firing temperature, the chemical composition of pure carbon, sulfur, harmful ingredients minimal absorption rate.

- Product good degree of graphitization, improve the original form of liquid iron nuclear capability. Ductile iron ball to increase the number of ink in breeding, increasing the graphite furnace liquid iron nuclei. Refined, uniform distribution of the graphite in the cast.

- excellent performance and stability.

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4< span=""> | <1< span=""> | <1< span=""> | <0.3< span=""> | 0-30mm |

CR-94 | ≥94 | <4< span=""> | <1< span=""> | <1< span=""> | <0.3< span=""> | |

CR-93 | ≥93 | <6< span=""> | <1< span=""> | <1< span=""> | <0.4< span=""> | |

CR-92 | ≥92 | <7< span=""> | <1< span=""> | <1< span=""> | <0.4< span=""> | |

CR-91 | ≥91 | <8< span=""> | <1< span=""> | <1< span=""> | <0.4< span=""> | |

CR-90 | ≥90 | <8.5< span=""> | <1.5< span=""> | <2< span=""> | <0.4< span=""> | |

Carbon rasier Packing:

- Carbon rasier waterproof bags 25KG / bag, plus tons of bags or trays

- Also provide suitable package according to your needs.

- Q:What is carbon neutral shipping?

- The concept of carbon neutral shipping involves offsetting or balancing the carbon emissions produced during the transportation of goods by sea, air, or land. Its goal is to minimize the environmental and climate impact of shipping. Shipping contributes to greenhouse gas emissions by burning fossil fuels, primarily heavy fuel oil in ships' engines. This releases carbon dioxide (CO2), nitrogen oxides (NOx), sulfur oxides (SOx), and particulate matter into the atmosphere, contributing to global warming and air pollution. To achieve carbon neutrality in shipping, different strategies can be used. One common approach is carbon offsetting, which involves investing in projects that remove or reduce an equivalent amount of CO2 from the atmosphere. This can include reforestation, renewable energy projects, or methane capture initiatives. By supporting these projects, shipping emissions are balanced out, resulting in a net-zero carbon footprint. Another way to achieve carbon neutrality is by using alternative fuels and energy-efficient technologies. Biofuels, hydrogen, and electric propulsion systems can significantly reduce or eliminate carbon emissions from ships. Optimizing shipping routes and vessel design can also reduce fuel consumption and emissions. Collaboration between shipping companies, governments, and international organizations is crucial to promote carbon neutral shipping. This includes setting industry-wide emission reduction targets, implementing stricter regulations, and providing incentives for sustainable practices. While carbon neutral shipping is a positive step towards addressing climate change, it should be seen as a transitional measure towards a fully decarbonized shipping sector. Continued research and development in clean technologies, along with the adoption of sustainable practices, are essential for long-term environmental sustainability in the shipping industry.

- Q:How are carbon-based polymers synthesized?

- Carbon-based polymers are synthesized through a process known as polymerization. This involves the chemical reaction of monomers, which are small molecules, to form long chains of repeating units, known as polymers. Carbon-based polymers, also known as organic polymers, are composed of carbon atoms bonded together in a backbone structure. There are various methods for synthesizing carbon-based polymers, but the most common one is called addition polymerization. In this process, monomers with unsaturated carbon-carbon double bonds, such as ethylene or propylene, undergo a reaction called addition polymerization. This reaction is initiated by a catalyst, which can be heat, light, or a chemical initiator, and it causes the monomers to join together, forming a polymer chain. Another method for synthesizing carbon-based polymers is condensation polymerization. In this process, two different types of monomers react with each other, eliminating a small molecule, such as water or alcohol, as a byproduct. The remaining monomers then continue to react, forming a polymer chain. Examples of polymers synthesized through condensation polymerization include polyesters and polyamides. In addition to these methods, there are also other techniques used to synthesize carbon-based polymers, such as ring-opening polymerization, which involves the opening of cyclic structures to form linear polymer chains, and step-growth polymerization, which involves the reaction of two or more monomers with reactive end groups. Overall, the synthesis of carbon-based polymers involves the combination of monomers through various chemical reactions to form long chains of repeating units. These polymers have a wide range of applications in industries such as plastics, textiles, and electronics, due to their desirable properties such as strength, flexibility, and thermal stability.

- Q:What is carbon fiber reinforced plastic?

- Carbon fiber reinforced plastic (CFRP) is a composite material made by combining carbon fibers with a polymer matrix, typically epoxy resin. It is known for its exceptional strength-to-weight ratio, making it a lightweight alternative to traditional materials like steel and aluminum. The carbon fibers provide the material with high tensile strength and stiffness, while the polymer matrix helps to distribute the load and provide durability. The manufacturing process of CFRP involves layering carbon fiber sheets or fabrics and impregnating them with the polymer resin. This combination is then cured under high temperature and pressure to create a solid and rigid structure. The resulting material is incredibly strong, yet significantly lighter than other materials of similar strength, such as steel. CFRP finds numerous applications across various industries due to its unique properties. It is commonly used in aerospace and automotive sectors to reduce the weight of components and improve fuel efficiency. Additionally, it is used in sports equipment, such as bicycles, tennis rackets, and golf clubs, as it allows for better performance and maneuverability. CFRP is also utilized in construction, where its high strength and resistance to corrosion make it suitable for reinforcing structures like bridges and buildings. Overall, carbon fiber reinforced plastic is a versatile and high-performance material that combines the strength of carbon fibers with the flexibility of a polymer matrix. Its lightweight nature and exceptional mechanical properties make it a popular choice across industries where strength, weight reduction, and durability are crucial factors.

- Q:How does carbon occur in nature?

- Carbon occurs in nature in various forms and is one of the most abundant elements on Earth. It is found in the atmosphere, in the Earth's crust, and in living organisms. In the atmosphere, carbon exists primarily as carbon dioxide (CO2), which is produced through natural processes such as respiration, volcanic activity, and the decay of organic matter. This CO2 is then absorbed by plants during photosynthesis to produce energy and release oxygen. Carbon is also present in other greenhouse gases like methane (CH4), which is produced by natural processes such as the decomposition of organic matter in wetlands and the digestive processes of certain animals. In the Earth's crust, carbon is found in various minerals such as limestone, dolomite, and graphite. These minerals are formed through the deposition and accumulation of marine organisms, such as shells and skeletons of marine organisms, over millions of years. Carbon is also a key component of fossil fuels, including coal, oil, and natural gas, which are formed from the remains of ancient plants and animals buried and subjected to high pressure and temperature over time. Furthermore, carbon is an essential element for all living organisms and is the basis of organic chemistry. It is the key component of all organic matter, including carbohydrates, proteins, lipids, and nucleic acids, which form the building blocks of life. Carbon cycles through various biological processes, such as photosynthesis, respiration, and decomposition, allowing it to be continually recycled within ecosystems. Overall, carbon occurs naturally in the environment in different forms and plays a crucial role in the Earth's climate system, geological processes, and the sustenance of life.

- Q:What are the impacts of carbon emissions on wildlife?

- Carbon emissions have a significant impact on wildlife as it contributes to climate change, leading to habitat loss, changes in migration patterns, and increased vulnerability to disease and extinction. Additionally, the acidification of oceans due to increased carbon dioxide levels affects marine life, disrupting food chains and damaging coral reefs. Overall, carbon emissions pose a grave threat to the survival and well-being of various species.

- Q:What is carbon offsetting in aviation?

- Carbon offsetting in aviation is a mechanism that aims to neutralize the carbon emissions produced by the aviation industry. As airplanes are a significant source of greenhouse gas emissions, carbon offsetting provides a way for airlines and passengers to take responsibility for their carbon footprint and contribute to the fight against climate change. The process of carbon offsetting involves calculating the amount of carbon dioxide and other greenhouse gases emitted during a flight and then investing in projects that reduce an equivalent amount of emissions elsewhere. These projects can include renewable energy initiatives, forest conservation, or methane capture projects. The idea is that the emissions reduced or removed by these projects offset the emissions produced by the aviation industry. To participate in carbon offsetting, airlines or passengers can purchase carbon offsets, which are essentially credits representing the reduction or removal of one metric ton of carbon dioxide or its equivalent. These offsets are generated by certified projects that meet strict standards and are independently verified. By investing in carbon offsets, the aviation industry can contribute to global efforts to reduce greenhouse gas emissions and mitigate the impact of air travel on climate change. It allows airlines and passengers to take immediate action to counteract the environmental consequences of flying, as the reduction or removal of emissions from offset projects helps to balance out the emissions produced by air travel. Carbon offsetting in aviation is not a means to justify or ignore the need for long-term solutions to reduce emissions from aircraft. It should be seen as a complementary measure to other strategies such as investing in more fuel-efficient aircraft, using sustainable aviation fuels, and implementing operational improvements. However, carbon offsetting does provide a valuable tool to mitigate emissions in the short term while the aviation industry works towards more sustainable practices.

- Q:What is the density of carbon?

- The density of carbon depends on its form. The most common form of carbon is graphite, which has a density of 2.267 grams per cubic centimeter (g/cm³). However, another form of carbon called diamond has a much higher density of 3.515 g/cm³. So, it is important to specify which form of carbon we are referring to when discussing its density.

- Q:How are carbon fibers used in manufacturing?

- Carbon fibers are used in manufacturing for their exceptional strength, light weight, and high stiffness properties. They are commonly used as reinforcement materials in various industries such as aerospace, automotive, sports equipment, and wind energy. Carbon fibers are incorporated into composites to enhance the strength and durability of products, making them ideal for applications where weight reduction and structural integrity are crucial.

- Q:How does carbon impact the stability of savannah ecosystems?

- Carbon plays a crucial role in the stability of savannah ecosystems. It is an essential element for all living organisms and is involved in various ecological processes. Carbon is primarily present in the form of organic matter, which is vital for the growth and development of plants, the primary producers in these ecosystems. In savannahs, carbon impacts stability in multiple ways. Firstly, carbon dioxide (CO2) is a key component of the Earth's atmosphere and plays a significant role in regulating the global climate. Savannas are known for their ability to sequester and store large amounts of carbon in their vegetation and soils. This carbon storage helps mitigate climate change by reducing the amount of CO2 in the atmosphere. Furthermore, carbon is essential for plant growth through photosynthesis. Savanna plants, such as grasses and scattered trees, utilize carbon dioxide from the air, converting it into carbohydrates and other organic compounds. This process not only provides plants with energy but also contributes to the overall productivity of the ecosystem. The stability of savannah ecosystems also depends on the interaction between plants and animals. Carbon-rich vegetation serves as a food source for herbivores, such as zebras and antelopes, which in turn support predators like lions and hyenas. The carbon cycle ensures a continuous flow of energy and nutrients throughout the food web, maintaining the balance and stability of the ecosystem. Moreover, the carbon content in savannah soils influences their fertility and ability to retain moisture. Organic matter, derived from decaying plant material, improves soil structure, nutrient availability, and water holding capacity. This, in turn, supports the growth of vegetation and sustains the diverse array of species found in savannah ecosystems. However, human activities, such as deforestation, agricultural practices, and the burning of fossil fuels, are altering the carbon balance in savannahs. Deforestation removes carbon-rich trees and plants, reducing the overall carbon storage capacity of the ecosystem. Additionally, the release of carbon dioxide from the burning of fossil fuels contributes to the greenhouse effect and climate change, which can disrupt the stability of savannah ecosystems. In conclusion, carbon plays a critical role in maintaining the stability of savannah ecosystems. It influences climate regulation, supports plant growth, provides energy for the food web, and enhances soil fertility. However, human activities that disrupt the carbon balance in these ecosystems can have detrimental effects on their stability and overall health. Therefore, efforts to conserve and restore savannah ecosystems are essential for preserving their carbon storage capacity and ensuring their long-term stability.

- Q:How does carbon affect the preservation of historical artifacts?

- Carbon can have both positive and negative effects on the preservation of historical artifacts. On one hand, carbon-based materials such as paper, wood, and textiles are susceptible to degradation over time. These artifacts can be easily affected by environmental factors such as temperature, humidity, and exposure to pollutants, leading to their decay. Carbon-based materials can also be attractive to pests like insects and rodents, further accelerating their deterioration. On the other hand, carbon-based materials like charcoal and carbonates can play a crucial role in the preservation of artifacts. Charcoal, for example, can be used to date artifacts through carbon dating, providing valuable insights into their age and historical significance. Carbonates, such as calcium carbonate found in limestone, can act as protective coatings, forming a barrier against environmental factors and preventing further decay. Moreover, carbon-based conservation treatments, such as consolidation with adhesives or impregnation with polymers, can help stabilize and strengthen fragile artifacts. These treatments can increase the artifact's resistance to environmental factors and provide structural support, extending its lifespan for future generations. It is important to note that while carbon-based materials can impact the preservation of historical artifacts, other factors like light exposure, handling, and storage conditions also play significant roles. Therefore, a comprehensive preservation strategy should consider all these factors to ensure the longevity and conservation of these valuable historical artifacts.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Recarburizer low S low N carbon additive carbon riser

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 500000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches