PVDF Aluminium Composite Panel with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of PVDF Aluminium Composite Panel Description:

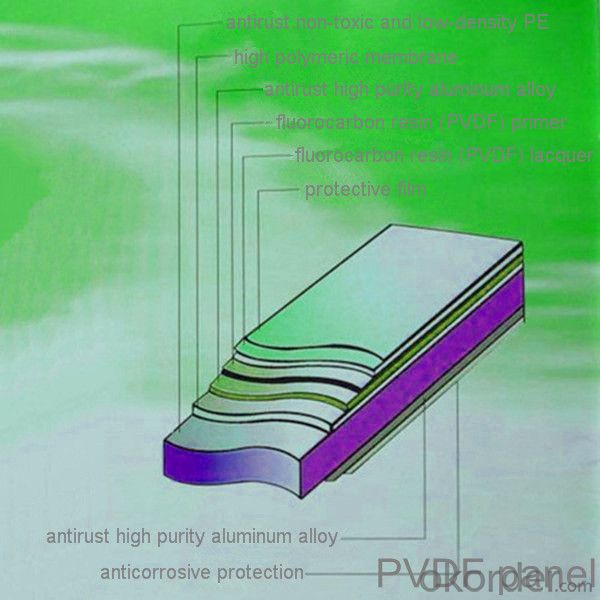

By adopting PVDF paints from the two toppest paint supplier: American PPG and Sweden Beckers, Megabond PVDF Aluminum Composite Panel is the most ideal material for facade cladding, curtain wall cladding and other outdoor using purpose.

PVDF is short for Polyvinlylidene Fluoride, the color will have no obvious change within 15 to 20 years when it’s applied outdoor. PVDF paint should be 2-layer coating or 3-layer coating, and Painting Thickness ≥25um., Fluorocarbon Powder ≥70%.

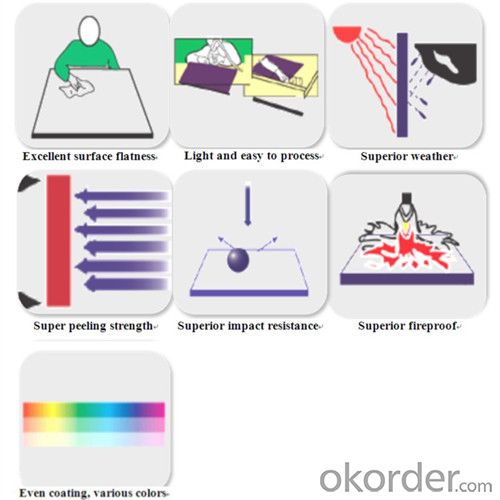

2.Main Features of the PVDF Aluminium Composite Panel :

1) Building exterior curtain wall, purdah wall;

2) Decoration and renovation additions for old buildings;

3) Decorations of interior walls (ceilings, partitions, bathrooms, cabinet, counter,

video wall, shield for doors windows, skirting, kitchens and balconies.)

4) Shop door decorations;

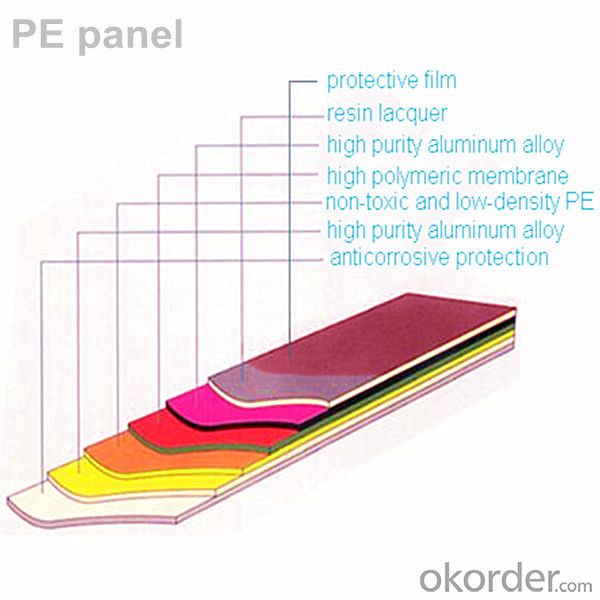

3. PVDF Aluminium Composite Panel Image:

4. PVDF Aluminium Composite Panel Specification

| Aluminum alloy | AA1100 series,AA3003 series |

| Aluminum skin | 0.30mm,0.40mm,0.45mm,0.50mm |

| Thickness | 4mm,5mm,6mm |

| Width | 1220mm,1250mm,1500mm,1575mm |

| Length | up to 6000mm |

| Color | 30 kinds.Special color available upon request |

5.FAQ

1).How to choose the panel thickness for different usages?

Exterior usage: 4mm panel with 0.30mm,0.40mm or 0.50mm aluminum skin, better in PVDF coating.

Interior usage: 3mm panel with 0.10mm,0.15mm or 0.21mm aluminum skin, PE coating is ok.

2). How to check whether this product is in good quality?

A. First is to see whether the surface is smooth enough, no ripples, bubbles and scratches.

B. Second is to check whether the panel thickness and aluminum skin thickness is thick enough.

C. To check the core material, whether it's easy broken.

D. To test the peel strength between aluminum skin and the core .

E. See whether company is normal manufacturer, which have ISO, CE, SGS certificate.

....

3). How to confirm the color for what you want?

You can contact me for our color card.

You can also choose a color from the RAL/Panton color card.

- Q:What are the folds of aluminum

- Aluminum-plastic composite board slot can generally open V-groove, U-slot, etc., several typical slotted as shown in Figure 1. Aluminum-plastic composite panel plate in the cutting board to take into account the size of the fold , Generally add about 25mm on each side. Cut the composite board needs four sides of the planing slot, that is cut to a certain width of the inner layer of aluminum and plastic layer, slot depth must be strictly controlled in the front aluminum plate at least 0.3mm thick plastic core To ensure that the aluminum-plastic composite panels have sufficient toughness to prevent the fold at the aluminum skin fracture, and then folded into a 90 ° angle, so the board surface weight and curtain wall at any time will be positive and negative wind load pressure by the four sides 0.5mm aluminum plate to bear, therefore, slotting is the aluminum-plastic composite panel panel of the weakest link, but also under the wind load under the first destruction of the site

- Q:Aluminum panels are used in what areas, can not be more detailed.

- Aluminum-plastic composite panel referred to as aluminum-plastic plate, is made by the surface treatment and coated with aluminum paint as the surface, polyethylene plastic plate as the core layer, after a series of process processing complex made of new materials.

- Q:What is the main purpose of aluminum-plastic composite panels?

- The main purpose of aluminum-plastic composite panels is used for building curtain walls and architectural interior and exterior decoration. The development of aluminum-plastic panels mainly in the construction industry, building decoration industry-based.

- Q:What are the specifications of aluminum-plastic plates?

- Category: According to the burning performance of curtain wall board is divided into ordinary type and flame retardant type. Flame retardant type according to the fire level is divided into A and B level.

- Q:30-storey residential building roof concrete flower frame decorated with aluminum-plastic plate, please apply to apply lightning belt can not do? Using aluminum-plastic plate grounding

- It is recommended to take the mine to do, can not cut corners to save trouble.

- Q:What is the difference between flexible ceilings and aluminum planks?

- 2 kinds of not a material, aluminum-plastic plate is hard, can not shape. Flexible ceilings are a lot of material

- Q:Is the aluminum composite board the same as the aluminum composite panel?

- The second point that the aluminum composite panels covered by the product line will be more than aluminum-plastic composite panels,

- Q:The status of aluminum - plastic plate products

- Aluminum-plastic curtain wall products as a kind of aluminum curtain wall products, and single-layer aluminum curtain wall and honeycomb aluminum curtain wall, compared with easy processing performance, economical and practical, excellent quality and a series of advantages, is the most widely used aluminum curtain wall products, The largest variety. It is the series of advantages of aluminum-plastic curtain wall, which has led to the development of aluminum-plastic curtain wall in China for more than ten years. Figure 3 for our own design, processing, installation of aluminum-plastic curtain wall project. However, the current situation of aluminum-plastic curtain wall in China and revealed a series of problems, many of them are also caused by the abuse of these advantages.

- Q:Aluminum-plastic plate production line inverter has a specific role, can specifically say it?

- Automatic spraying equipment work process is through the conveyor chain will be sprayed into the high temperature oven, after a series of baking process so that the coating attached to the paint to be sprayed, and then sent by the transmission chain, the workers removed from the chain inspection, qualified Warehousing. Its electrical control system requirements can be adjusted according to different spray conveyor chain speed, in order to ensure adequate high temperature heating time, theoretically realized should be very simple, but because the conveyor chain is longer, the use of a single motor drag is very difficult, so the design Using two motors, which in turn a key issue is how to ensure that the two motor synchronization? Because if the synchronization will lead to the accumulation or breakage of the conveyor chain lead to the production can not be carried out, the three crystal inverter in the life of the speed of the death cycle control effectively solve the synchronization problem.

- Q:Plywood attached to the board how to deal with degumming? What kind of glue how to deal with?

- The best way is to remove the re-installation, the original aluminum-plastic plate in the demolition process, certainly deformation is very powerful.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVDF Aluminium Composite Panel with Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords