Fiberglass Geogrid 100KN/100KN for Constructional Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

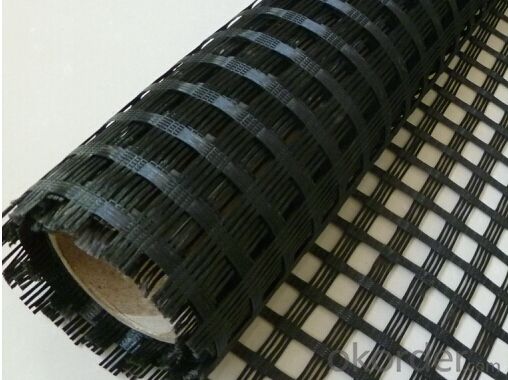

1.Description of Fiberglass Geogrid 100KN/100KN

CMAX fiberglass geogrid is made from glass fiber by weaving technology and coating treatment.

2.Specification of Fiberglass Geogrid 100KN/100KN

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

3.Technical Data Sheet of Fiberglass Geogrid 100KN/100KN

Item | CMAX30-30 | CMAX50-50 | CMAX80-80 | CMAX100-100 | CMAX120-120 | CMAX150-150 | |

Mesh Size(mm) | 25.4 x 25.4 or 12.5 x 12.5 or 50.8x 50.8 | ||||||

Breaking strength | Warp direction | 30 | 50 | 80 | 100 | 120 | 150 |

Across warp | 30 | 50 | 80 | 100 | 120 | 150 | |

Elongation at break % | Warp direction | 4 | |||||

Across warp | 4 | ||||||

Thermal tolerance (℃) | -100 ~280 | ||||||

Width(m) | 6 | ||||||

4.Property of Fiberglass Geogrid 100KN/100KN:

1). High strength, low elongation;

2). Heat-resistant, high modulus.

3). Light weight, good flexibility.

4). Anti-erosion, long life time.

5.Application of Fiberglass Geogrid 100KN/100KN

1). Roadbed reinforcement, prevent road surface crack.

2). Road reconstruction

3). Soft soil reinforcement, improve road whole bearing capacity and prevent crack.

FAQ :

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

4. Do you accept third party test?

Yes, we can accept any third party test before shipment, like SGS, TRI, etc.

- Q: Are there any specific maintenance requirements for geogrids?

- Yes, geogrids typically have specific maintenance requirements. These requirements may include regular inspection for damage or degradation, cleaning to remove any debris or sediment that may accumulate, and occasional repair or replacement if necessary. It is important to follow the manufacturer's recommendations and guidelines for maintenance to ensure the optimal performance and lifespan of geogrids.

- Q: Are geogrids resistant to chemical attack from soil contaminants?

- Yes, geogrids are generally resistant to chemical attack from soil contaminants. Due to their high tensile strength and chemical stability, geogrids can withstand exposure to various soil contaminants without significant deterioration. However, the specific resistance may vary depending on the type of geogrid material and the nature of the soil contaminants.

- Q: Can geogrids be used in stormwater management systems?

- Yes, geogrids can be used in stormwater management systems. Geogrids are often utilized to reinforce and stabilize soil in stormwater management applications such as retaining walls, embankments, and erosion control measures. They can help improve the overall performance and longevity of stormwater management structures by enhancing soil stability and preventing erosion.

- Q: How do geogrids improve the stability of steep slopes?

- Geogrids improve the stability of steep slopes by providing reinforcement and increasing the shear strength of the soil. They are placed within the soil mass to distribute the applied loads more evenly, reducing the potential for slope failure. Additionally, geogrids enhance the interlocking of soil particles, preventing soil movement and erosion, which ultimately contributes to improved slope stability.

- Q: How do geogrids help in reducing the carbon footprint of a project?

- Geogrids help in reducing the carbon footprint of a project by providing a sustainable and environmentally-friendly solution for soil stabilization and reinforcement. By using geogrids, less excavation and material are required, reducing the need for transportation and minimizing energy consumption. Additionally, geogrids can extend the lifespan of infrastructure, reducing the need for frequent repairs and replacements, which further reduces carbon emissions associated with construction.

- Q: Can geogrids be used in reinforcement of underground tunnels and caverns?

- Yes, geogrids can be used in the reinforcement of underground tunnels and caverns. Geogrids are high-strength materials that can provide stability and support to the surrounding soil or rock mass in underground structures. They can be used to reinforce the tunnel walls, prevent ground movement, and increase the overall strength of the tunnel structure. Geogrids are commonly used in geotechnical engineering projects to enhance the stability and longevity of underground tunnels and caverns.

- Q: Can geogrids be used in reinforcement of retaining walls?

- Yes, geogrids can be used in the reinforcement of retaining walls. Geogrids are commonly used to enhance the stability and strength of retaining walls by providing additional reinforcement. They help distribute the forces exerted by the soil and improve the overall performance and longevity of the retaining wall structure.

- Q: How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing soil stabilization and reinforcement, reducing the need for excessive excavation and material usage. This results in minimized disturbance to natural habitats, reduced waste generation, and lower carbon emissions, ultimately promoting sustainable construction practices.

- Q: How do geogrids improve the load distribution in pavements?

- Geogrids improve load distribution in pavements by providing a reinforcement layer that enhances the structural integrity of the pavement system. They distribute the load more evenly across the pavement surface, reducing stress and preventing the formation of cracks and deformations. Geogrids also enhance the overall strength and stability of the pavement, improving its lifespan and reducing maintenance costs.

- Q: What is the quota of two-way steel plastic composite geogrid

- 40 thick C20 concrete sets in the decoration of the 1-31, and then set the 1-32 coefficient selection of 2, according to area calculation.

Send your message to us

Fiberglass Geogrid 100KN/100KN for Constructional Reinforcement

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords