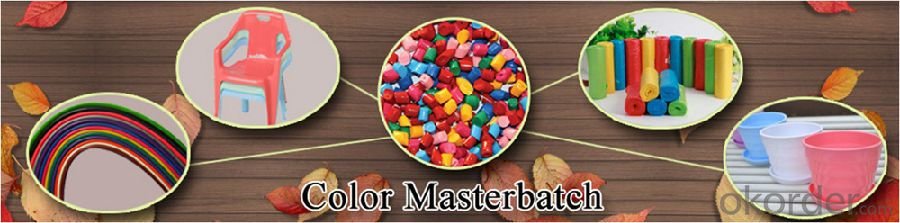

Plastic Color Masterbatch for Injection Molding, Wire Drawing, Extrusion Craft

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color masterbatch is made of inorganic and organic pigment,dye and suitable additives auxiliaries.

Widely used for Packing film, bottle,cap,hose,all kinds of containers as well as toys, household appliance,office supplies , building pipe, ect.

Advantage of Color Masterbatch:

1.This series color masterbatches are of high concentration pigment with bright colors.

2.When they are used in resins, it shows better dispersing and stablility performance.

3.Also the mixture has the highest mechanical intensity preservation rate.

4.A broad standard color range available from stock as well as tailor made products develop according to customer requirements.

Features of Color Masterbatch:

-Standard, universal, or custom colors

-Carriers optimized for easy processing

-Production orders shipped in 5 days

Additive amount:Compound masterbatch and resin with 1:25--50 uniformly (according to the products requirements).

It can be used after drying

Application:Blow molding, Injection molding, wire drawing, extrusion craft.

Packaging:Paper-plastic compound bags,or PE bags,25kg net weight/bag.

Product Pictures of Color Masterbatch

- Q:What are the raw materials for producing plastic films?

- Film type: PVA coated high barrier film, biaxially oriented polypropylene film (BOPP) and low density polyethylene film (LDPE), polyester film (PET), nylon film (PA), polypropylene (CPP) film, etc..

- Q:What kinds of plastic properties can be divided into thermal properties?

- A. thermoplastic(a) polyvinyl chloride (PVC)Is the most widely used plastic varieties. Polyvinyl chloride resin is made from poly (vinyl chloride) monomer. According to the amount of plasticizer, it is divided into hard PVC and soft PVC. The former adds 30~70 phr of plasticizer <5 in 100 heavy resins, and the latter adds plasticizers.Physical properties: the relative density of hard PVC is 1.35 to 1.60, which is 1 / 5 of carbon steel; the relative density of soft PVC is 1.2 ~ 1.4.The water absorption rate of hard PVC is very low. The water absorption rate in long-term immersion in water is <0.5%; the soaking water is 24h, and the water absorption is 0.05%. The permeability of PVC is very low.The glass state temperature of PVC is 80~85 DEG C, the viscosity is 180 DEG C, the decomposition temperature is 240~260 DEG C (including stabilizer), and the brittleness temperature is -50 ~ -60 DEG C.The recommended temperature range of hard PVC is, in principle, maintained in terms of brittleness and glass temperature. If it is used above 50 degrees, necessary measures should be taken.The pure PVC, without stabilizers, begins to decompose at 150 C, releases hydrogen chloride, and further accelerates its decomposition. It decomposes faster than 180 DEG C. The polyvinyl chloride with the stabilizer decomposes the temperature to 240~260 degrees centigrade, but breaks down hydrogen chloride if used for 220 years. The material changes from dark grey to yellow brown, or even black. Therefore, in welding, we should try to avoid this phenomenon, the linear expansion coefficient of hard polyvinyl chloride is (5~6) X10-5 / DEG, 5-6 times larger than carbon steel. Therefore, when installing polyvinyl chloride pipes, expansion joints or bracing shall be installed to prevent deformation. When polyvinyl chloride is used as lining or bonding with other materials, the peeling phenomenon may be considered when heated.

- Q:What material is best for plastic gears?

- The most commonly used is the POM. It can be made of carbon fiber reinforced, more stable size, of course, can also use high-end engineering plastics, such as: PEEK, SP-1, Teflon, LR, and so on. For different occasions, different characteristics of the use of choice

- Q:PP plastic stool surface with those raw materials, what is the ratio?

- In general plastics, PP has the best heat resistance, and its thermal deformation temperature is 80-100 DEG C and can be boiled in boiling water.

- Q:What does plastic material include?

- The main raw material of plastics is oil and natural gas, that is, carbon hydrogen compounds. First, the appropriate large molecules in petroleum and natural gas are extracted, first split into monomers, and then polymerized into polymers to become plastic.

- Q:PVC what is the difference between raw and recycled raw materials?

- Because the recycled material is a result of high temperature dissolved, it is likely to emit a pungent flavor, this odor may be harmful to humans.

- Q:What is plastic film material?

- Plastic film material is plastic micelle, which is made by petrochemical enterprises from petroleum refining.

- Q:I do PA, PC, PP and other plastic raw materials can be used in the eye frame and lens it

- In general, the lenses of PC need to be covered with scratch resistant protective films, which will be sufficient for better aging, and most lenses for children.

- Q:Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- The so-called plastic raw material electroplating grade means that the particle of the plastic material is high in purity and high in polarity, and is easy to be evenly adhered to the metal particles before the plating.

- Q:ABS plastic storage conditions

- If it is ABS raw materials, storage: rainproof, moisture-proof, anti lightPacking is best provided with a PE inner bag for moisture proofThere is no place to pay more attention.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Plastic Color Masterbatch for Injection Molding, Wire Drawing, Extrusion Craft

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords