Non-combustible,non-corrosive rock wool blanket with wire mesh Water repellent,asbestos fre

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

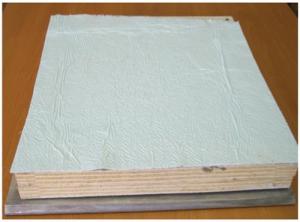

CNBM rock wool blanket with wire mesh Overview:

CNBM rock wool blanket with wire mesh is a robust insulation product stitched on one side with galvanized or stainless steel wire mesh and comes in various thickness and density.

CNBM rock wool blanket with wire mesh Product Specifications¼

Density(kg/m3) | Width(mm) | Thickness(mm) | Length(m) | Facing |

60-150 | 600 | 30-200 | 2.5 , 3 , 5 | wire mesh |

We can make special production according to your requirement.

Rock Wool Blanket With Wire Mesh Technical Parameters:

Item | Unit | Index | Standard |

Density | Kg/m3 | 60-200kg/m3 | GB5480.3 |

Average value of fiber | um | 4-7 | GB5480.4 |

Slag ball content (granule diameter) | % | 6 | GB5480.5 |

Volume water absorption | % | 2 | GB/GB16401-1996 |

Heat absorption | % | 1 | GB5480.7 |

Moisture resistivity | % | 98 | B10299-88 |

- Q:Composite manhole cover or cast iron well cover?

- The new composite made of color composite manhole covers can reach 90 tons, which can be used as a substitute for cast iron covers, and the northern color is the patent name of Beijing Pan Asia Electric

- Q:Why is unsaturated polyester resin used in sheet molding? Why don't short fiber moulding plastics use unsaturated polyester resins?

- BMC SMC produced a good sheet or mass, there is a mature thickening process, the temperature should be placed for more than a dozen hours or more time to mature thickening.

- Q:Seeking better SMC manufacturers in the industry, it is best to write more, thank you!

- SMC is divided into domestic joint venture factory production, pure Japanese imports on these two, domestic production of product quality with pure Japanese production has certain differences, but not very big, layman see.

- Q:How is glass fiber reinforced plastic water tank made?

- Glass fiber reinforced plastic water tank; made of resin glass fiber filler; SMC sheet; molded into water tank plate; assembled into glass reinforced plastic water tank

- Q:What is a sheet of material? Is it plastic? What is it used for?

- The sheet refers to the resin (or in the process of using monomer polymerization) as the main ingredient, such as plasticizers, fillers, lubricants, additives such as colorants as auxiliary components, can flow in the process of forming materials. In the material industry, SMC is commonly known as sheet material, and the full name of Chinese is: sheet molding plastics. The utility model relates to a premix for molding. In the glass fiber reinforced plastic industry, SMC is widely used. The large areas of sheet materials, such as automobile shell, water tank, seat and so on, are generally molded by SMC compression and heating.

- Q:Thickening mechanism of Magnesium Oxide by SMC

- Magnesium Oxide in the production process, according to the needs of glass steel manufacturers to change the Magnesium Oxide indicators, in general, the active Magnesium Oxide in the glass steel industry is relatively good.

- Q:Is the gas released from the heating of the SMC sheet poisonous?

- If unsaturated polyester resin is not doped with toxic solvents, the gases usually released after heating are not poisonous.

- Q:What composite material is used for composite manhole covers?

- The composite manhole cover adopts high temperature and high pressure molding technology with high degree of polymerization, large density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution, no maintenance, etc..

- Q:What are the raw materials for composite manhole covers?

- The composite manhole cover adopts high temperature and high pressure molding technology with high degree of polymerization, large density, good impact resistance and tensile strength, and has the advantages of wear resistance, corrosion resistance, no rust, no pollution, no maintenance, etc.. General composite manhole covers are also BMC composite cover and SMC composite manhole cover. SMC polymer composite manhole cover, Beijing Pan Asia Telecom's reliable, but also applied for the color of the patent

- Q:What is polymer composite cable trench cover plate?

- But on the actual sales market, the BMC material plus steel pressed into the cover plate, glass fiber reinforced plastic grille also become high polymer composite material cover plate.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Non-combustible,non-corrosive rock wool blanket with wire mesh Water repellent,asbestos fre

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords