Insulation Bricks Or Insulation Fire Brick High Quality GJM23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Insulation Brick:

CMAX insulating firebricks are classified under temperature between 1100℃ to 1700℃, manufactured from high purity alumina clay..

2.Main features of Insulation Brick:

◆Light weight and low thermal conductivity ◆Low heat storage

◆Low iron and impurities ◆High thermal shock resistance

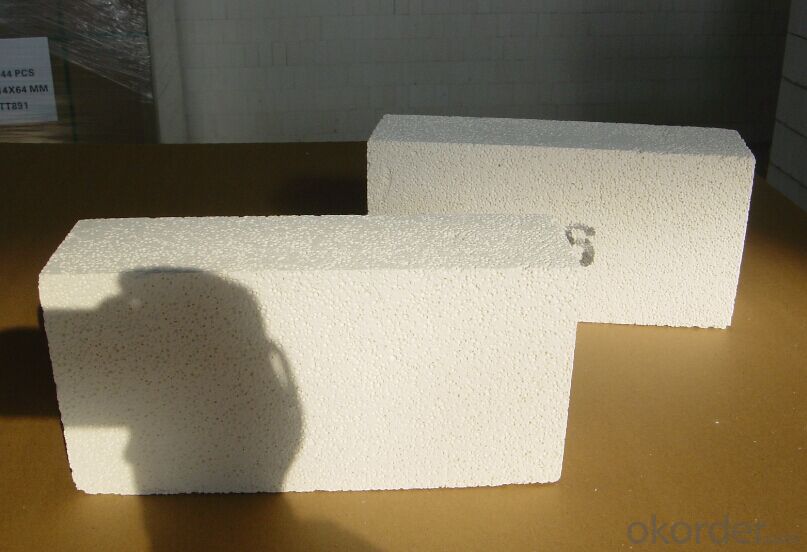

3. Insulation Brick Images:

4. Insulation Brick Technical Parameters

Our Insulation Brick contains 20, 23, 25,26, 28, 30, 32. Classification temperature is from 1100℃ to 1760℃. Density is from 0.52g/cm3 to 1.25g/cm3. As we all know, the company type is 23 and 26.

1) For the 23, its density is 0.52g/cm3, but some customer may require 0.8g/cm3, we can also meet your special require. Content of Al2O3 is about 45%.

2) For the 26, its density is 0.8g/cm3, but if you have other special requirement on that, pls also tell us. Content of Al2O3 is about 55%.

Application: CMAX insulating firebricks can be used as a hot face lining directly exposed to the heat or as a backup insulation layer in iron and steel mills, non-ferrous foundries, petrochemical, ceramic, glass. If you need other application picture, please contact with us

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about our Insulation Brick?

A world class manufacturer & supplier of InsulationBrick is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q:Are insulating fire bricks resistant to salt attack?

- Yes, insulating fire bricks are generally resistant to salt attack. They have a high resistance to chemical reactions and can withstand exposure to salts without significant deterioration.

- Q:Can insulating fire bricks be used in the construction of pottery molds?

- Yes, insulating fire bricks can be used in the construction of pottery molds. Insulating fire bricks are made from lightweight refractory materials that have excellent heat insulation properties. These bricks are specifically designed for applications that require high temperatures, such as pottery kilns. When constructing pottery molds, it is important to have materials that can withstand the intense heat of the kiln. Insulating fire bricks can withstand temperatures up to 3000°F (1650°C), making them suitable for pottery mold construction. They provide insulation to prevent heat loss and maintain consistent temperatures inside the kiln, which is essential for achieving the desired firing results. Furthermore, insulating fire bricks can be easily shaped and cut to fit the desired mold design. They are also lightweight, which makes them easier to handle during the mold construction process. Additionally, the insulating properties of these bricks help to reduce energy consumption by preventing excessive heat loss, making them cost-effective in the long run. Overall, insulating fire bricks are a suitable choice for constructing pottery molds due to their ability to withstand high temperatures, provide insulation, and be easily shaped to fit specific designs.

- Q:How do insulating fire bricks affect heating or cooling times?

- The unique thermal properties of insulating fire bricks have a notable impact on the duration of heating or cooling. These bricks possess low thermal conductivity, making them highly effective in reducing heat transfer through conduction. When employed for heating purposes, insulating fire bricks contribute to the retention of heat for longer periods. They serve as a protective shield, impeding the easy escape of heat from the system and ensuring its directed flow towards the desired area. Consequently, the heating process becomes more efficient as the heat remains effectively contained within the system, without dissipating rapidly. As a result, heating times are shortened due to the assistance of insulating fire bricks in sustaining a consistent temperature and preventing heat loss. Similarly, in cooling applications, insulating fire bricks assist in slowing down the rate of heat transfer. By minimizing the entry of external heat into the cooling system, these bricks support the maintenance of lower temperatures over an extended duration. This is particularly advantageous in situations requiring a steady and controlled cooling process. Overall, the utilization of insulating fire bricks can significantly alter the duration of heating or cooling by enhancing energy efficiency. These bricks function as a thermal barrier, minimizing heat transfer and maximizing the effectiveness of heating or cooling systems.

- Q:Can insulating fire bricks be used in paper mills?

- Yes, insulating fire bricks can be used in paper mills. Insulating fire bricks are commonly used in industrial applications, including paper mills, to provide thermal insulation and protect equipment from high temperatures. They help in maintaining optimal temperature levels and enhance energy efficiency in the paper production process.

- Q:Is it possible to repair damaged insulating fire bricks?

- Repairing damaged insulating fire bricks is indeed possible, and the method required will depend on the extent and type of damage. For minor cracks or chips, one can utilize a refractory mortar that is specifically designed to endure high temperatures and create a strong bond. This mortar can effectively fill in the gaps and restore the brick's integrity. However, if a larger section of the brick is damaged or completely missing, it may be necessary to replace the entire brick. In such a scenario, the damaged brick must be cautiously removed, and a new one can be installed with the appropriate refractory mortar. It is crucial to ensure that the repaired or replaced brick adheres to the original specifications and quality to guarantee proper insulation and structural integrity. It is highly recommended to seek advice from a professional or carefully follow the manufacturer's guidelines for the specific repair process.

- Q:Are insulating fire bricks resistant to spalling?

- Insulating fire bricks exhibit resistance to spalling. These bricks are specially engineered to endure elevated temperatures and thermal shock, rendering them highly immune to spalling. Spalling indicates the fracturing and fracturing of bricks owing to exposure to extreme heat. Composed of superior refractory materials with low thermal conductivity, insulating fire bricks restrict heat transmission and diminish spalling hazards. Moreover, these bricks boast a remarkable melting point, rendering them excellently suited for applications demanding high temperatures. Consequently, insulating fire bricks find widespread application in furnaces, kilns, and other environments characterized by elevated temperatures, where spalling poses a significant concern.

- Q:Can insulating fire bricks be used in pottery kilns?

- Pottery kilns can indeed utilize insulating fire bricks. These bricks, also referred to as refractory bricks, possess a specialized design that enables them to endure high temperatures and provide insulation to retain heat within the kilns. Alumina, silica, and other refractory materials are employed in the creation of these bricks, as they possess exceptional thermal resistance properties. The utilization of insulating fire bricks in pottery kilns aids in the maintenance of a consistent temperature, reduction of heat loss, and ensures efficient firing of clay and glazes. Moreover, these bricks contribute to the elongation of the kiln's lifespan by safeguarding the interior walls from extreme temperatures. Consequently, insulating fire bricks represent an ideal choice for pottery kilns and are extensively employed in the pottery industry.

- Q:Do insulating fire bricks have a high thermal stability?

- Yes, insulating fire bricks have a high thermal stability. These bricks are designed to withstand high temperatures without deteriorating or losing their insulating properties. They are made from high-quality refractory materials that can withstand extreme temperatures, making them ideal for applications where thermal stability is crucial. Insulating fire bricks have low thermal conductivity, which means they can effectively trap heat and prevent it from escaping. This property allows them to maintain stable temperatures in environments where heat retention is essential, such as furnaces, kilns, and other high-temperature industrial processes. Overall, insulating fire bricks are known for their excellent thermal stability, making them a reliable choice for applications that require insulation and protection against high temperatures.

- Q:Can insulating fire bricks be used in cryogenic applications?

- Yes, insulating fire bricks can be used in cryogenic applications. These bricks have low thermal conductivity and are capable of withstanding extremely low temperatures, making them suitable for insulation in cryogenic environments.

- Q:Are insulating fire bricks resistant to phosphoric acid?

- Phosphoric acid, being a strong acid, has the potential to react with and corrode various materials, including fire bricks. Although certain fire bricks may possess a degree of resistance to acidic conditions, insulating fire bricks are generally not equipped to endure prolonged exposure to phosphoric acid without experiencing notable deterioration. As a result, it is advisable to employ acid-resistant materials like acid-resistant bricks or linings when handling phosphoric acid or other potent acids.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulation Bricks Or Insulation Fire Brick High Quality GJM23 26

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 50000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords