Insulating Fire Bricks GJM26 for High Temperature Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What it the Insulating Fire Brick?

Insulating fire bricks (IFBs) are called soft bricks comparing to hard bricks or Fireclay bricks and they are light in weight. Insulating fire brick can be easily cut by handheld hack saw or other hand tools like chisel. Insulating firebricks have high porous rate and have excellent insulating properties.

What are the applications of Insulating Fire Brick?

Glass Industries

Ceramics Industries

Electrolytic Aluminum Industries

Iron & Steel Industries

Non-Ferrous Metals Industries

Power Generation Industries

Primary hot surface linings

Sulphur recovery equipment

Cracking Furnace; Conversion Furnace

Heating equipment or Heating Furnace, Even-heating Furnace, Heat-processing Furnace

What are the excellent features of Insulating Fire Brick?

High heat resistance and durability

Excellent insulating properties

Excellent resistance to thermal shock

Low thermal conductivity

Low heat storage

Excellent construction/compressive strength

Particularly suited to highest temperature applications above 1600°C or 2800°F

Structural integrity capable of dealing with erosive and abrasive environments

Low impurity

Precise dimensions

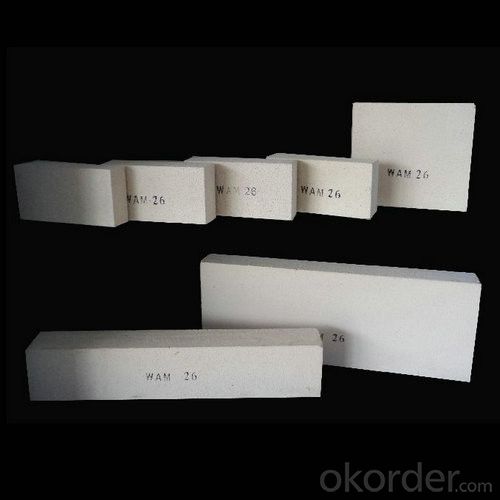

Image of Insulating Fire Brick

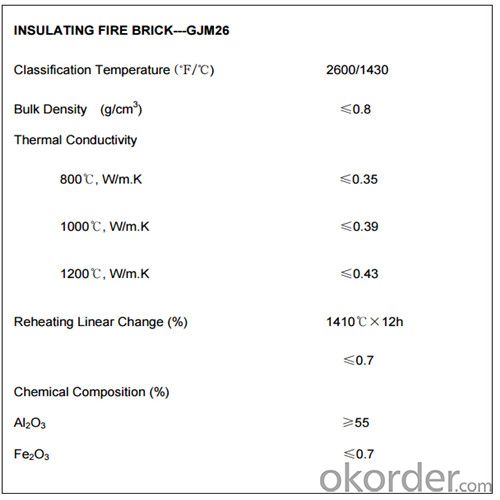

Technical Data of Insulating Fire Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:Are insulating fire bricks suitable for use in wood-fired ovens?

- Yes, insulating fire bricks are suitable for use in wood-fired ovens. These bricks are designed to withstand and retain high temperatures, making them ideal for wood-fired ovens that require heat insulation and retention. They help to create a more efficient and evenly heated cooking environment, allowing for better control of the oven's temperature and ensuring even baking and cooking results.

- Q:Can insulating fire bricks be used in the construction of flue liners?

- Yes, insulating fire bricks can be used in the construction of flue liners. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties. These bricks are made from lightweight materials such as vermiculite or perlite, which have low thermal conductivity. This makes them ideal for lining flues, as they can help to retain heat and improve the efficiency of the flue system. Additionally, insulating fire bricks are resistant to thermal shock and can withstand rapid temperature changes, which is important in flue applications where the temperatures can fluctuate significantly. Overall, using insulating fire bricks in the construction of flue liners can help to enhance the performance and safety of the flue system.

- Q:Are insulating fire bricks resistant to high-velocity gas flow erosion?

- Insulating fire bricks are generally capable of resisting erosion caused by high-velocity gas flow. These bricks are engineered to endure extreme temperatures and harsh conditions, including environments prone to erosion. They are crafted from top-notch refractory materials, like alumina and silica, renowned for their outstanding resistance to erosion and corrosion. Moreover, insulating fire bricks possess low thermal conductivity, aiding in minimizing heat loss and preserving their structural integrity even when subjected to high-velocity gas flow. Nonetheless, it is crucial to acknowledge that the precise level of resistance may differ depending on the unique composition and manufacturing techniques employed in creating the insulating fire bricks.

- Q:Can insulating fire bricks be used for insulation in smelting furnaces?

- Smelting furnaces can utilize insulating fire bricks for insulation purposes. These bricks are specifically designed to endure high temperatures while providing exceptional insulation capabilities. By possessing a low thermal conductivity, they can effectively retain heat within the furnace, preventing energy loss. This quality makes them an ideal option for smelting furnaces that necessitate elevated temperatures. Moreover, insulating fire bricks are lightweight, facilitating easy handling and installation within the furnace. Their durability and resistance to thermal shock allow them to withstand the extreme conditions of smelting processes. In conclusion, insulating fire bricks are a dependable and efficient choice for insulation in smelting furnaces.

- Q:Are insulating fire bricks resistant to weathering or aging?

- Yes, insulating fire bricks are generally resistant to weathering and aging. These bricks are designed to withstand high temperatures and harsh conditions, making them durable and long-lasting. They are often used in applications where exposure to extreme weather, such as rain, snow, and sunlight, is common. However, it is important to note that the specific composition and quality of the bricks can vary, so it is advisable to consult the manufacturer or supplier for detailed information regarding their weathering and aging resistance properties.

- Q:Are insulating fire bricks resistant to moisture or water damage?

- Insulating fire bricks possess a general resistance to moisture and water damage. Their low porosity and high density prevent water absorption. Moreover, they are usually crafted from materials like alumina or silica, which inherently resist moisture. Nevertheless, it must be emphasized that no material is entirely impervious to water, and continuous exposure to moisture can gradually impact the insulating fire bricks. Thus, it is advisable to take essential measures, such as applying suitable sealants or coatings, to heighten their resistance to moisture or water damage in specific scenarios.

- Q:Are there any safety precautions to consider when using insulating fire bricks?

- Yes, there are safety precautions to consider when using insulating fire bricks. Firstly, it is important to wear appropriate personal protective equipment, such as gloves and safety goggles, to protect against potential injuries. Additionally, due to the high temperatures involved, it is crucial to handle the bricks with care to avoid burns or related accidents. Adequate ventilation should be ensured to prevent the buildup of harmful gases and fumes. Lastly, it is essential to follow the manufacturer's instructions and guidelines for proper installation and usage to minimize any potential risks.

- Q:Can insulating fire bricks be used for insulation in flues?

- Yes, insulating fire bricks can be used for insulation in flues. These bricks are designed to withstand high temperatures and provide excellent thermal insulation, making them suitable for lining and insulating flue systems. They help to prevent heat loss, improve energy efficiency, and enhance the overall performance of the flue.

- Q:How do insulating fire bricks help reduce heat loss through conduction?

- Insulating fire bricks are specifically designed to minimize the loss of heat through conduction by utilizing their unique properties. These bricks are manufactured using a special lightweight refractory material, such as ceramic fibers or a combination of high-alumina and silica, which possess a low thermal conductivity. The low thermal conductivity of insulating fire bricks serves to diminish the transfer of heat through conduction. When heat is applied to one side of the brick, the material's low thermal conductivity prevents the rapid flow of heat to the other side. Consequently, less heat is lost through the brick via conduction, leading to enhanced insulation and energy efficiency. Moreover, insulating fire bricks often exhibit a high level of porosity, which results in the formation of air pockets within the material. These air pockets function as barriers to heat transfer since air is a poor conductor of heat. By ensnaring air within the structure of the brick, insulating fire bricks effectively decelerate the movement of heat, further reducing heat loss through conduction. Additionally, insulating fire bricks possess a high melting point, enabling them to endure extreme temperatures without distorting or deteriorating. This characteristic guarantees that the bricks can proficiently insulate against heat transfer even in high-temperature environments, such as furnaces or kilns. In conclusion, insulating fire bricks aid in diminishing heat loss through conduction by virtue of their low thermal conductivity, high porosity, and high melting point. These bricks capably restrict the transmission of heat from one side to the other, thereby minimizing energy loss and enhancing insulation efficiency.

- Q:Do insulating fire bricks expand and contract with temperature changes?

- Insulating fire bricks do indeed undergo expansion and contraction in response to temperature variations. Similar to all other materials, exposure to heat causes these bricks to expand, whereas cooling leads to their contraction. This expansion and contraction phenomenon arises from the material's thermal expansion coefficient, which dictates the degree of expansion or contraction in relation to temperature changes. It is crucial to acknowledge this characteristic when utilizing insulating fire bricks in situations that involve anticipated temperature fluctuations. Neglecting to account for the expansion and contraction may result in structural harm or the formation of cracks.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulating Fire Bricks GJM26 for High Temperature Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords