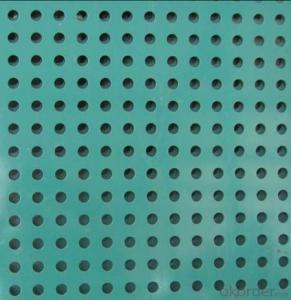

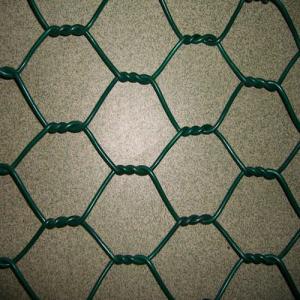

High Quality Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Material: | Type: | |||

| Application: | Weave Style: | Wire Diameter: | |||

| Technique: | Model Number: | Brand Name: | |||

| product name(stainless steel mesh): | stainless steel wire mesh usage: | stainless steel mesh other using: | |||

| stainless steel net characteristic: | stainless steel net other characteristic: | Stainless steel mesh deep processing: | |||

| Stainless steel net Further processing: | Stainless steel wire mesh weave: | Stainless steel wire mesh: | |||

| Stainless steel wire mesh wire diameter: |

Packaging & Delivery

| Packaging Detail: | packing:waterproof paper inside, plastic film outside, then pallet or wooden box. Stainless Steel Wire Cloth |

| Delivery Detail: | 10-15 day Stainless Steel Wire Cloth |

Specifications

Stainless Steel Wire Cloth

stainless steel mesh use very broad

wire mesh/filte net/wire cloth

Texture/SS304,316,430,201,320

- Q:How is steel wire mesh used in reinforcement of power plants and energy facilities?

- Due to its exceptional strength and durability, steel wire mesh is commonly employed in the reinforcement of power plants and energy facilities. It is primarily used in concrete structures to enhance their overall structural integrity and provide additional reinforcement. One of the primary uses of steel wire mesh in these facilities is in the construction of reinforced concrete walls and slabs. These structures must withstand high pressures, vibrations, and extreme temperatures. By incorporating steel wire mesh within the concrete, the load is distributed more effectively, preventing crack propagation and improving the strength and resilience of the structures. Steel wire mesh is also crucial for reinforcing concrete foundations, particularly in areas with weak soil conditions or when the load-bearing capacity needs to be increased. It improves the stability and load-carrying capacity of the foundations by providing additional tensile strength to counteract potential movements or settling. Another important application of steel wire mesh is in the reinforcement of concrete tunnels and pipelines within power plants and energy facilities. These structures carry high-pressure fluids or gases, and failure can have catastrophic consequences. Steel wire mesh reinforces the concrete, preventing cracks and ensuring the long-term durability and structural integrity of these critical components. Furthermore, steel wire mesh is used in the construction of concrete slabs and floors in power plants and energy facilities. These areas are subjected to heavy loads, frequent machinery movement, and exposure to chemicals or extreme temperatures. Reinforcing the concrete with steel wire mesh increases its load-bearing capacity, prevents cracking, and enhances resistance to wear and tear. Overall, steel wire mesh plays a vital role in the reinforcement of power plants and energy facilities. It provides enhanced strength, durability, and resistance to various external influences, ensuring the long-term stability and safety of these structures. This allows them to operate efficiently and reliably for many years.

- Q:How is steel wire mesh used in the telecommunications manufacturing industry?

- Steel wire mesh is widely used in the telecommunications manufacturing industry for various applications. One of the primary uses of steel wire mesh in this industry is for cable management. The mesh is used to organize and secure the various cables and wires used in telecommunications equipment. It helps to prevent tangling and ensures a neat and organized setup, which is crucial for efficient operations. Furthermore, steel wire mesh is also utilized for shielding purposes. In telecommunications, electromagnetic interference (EMI) can disrupt the quality of signals and affect the overall performance of equipment. Steel wire mesh acts as a shield by providing a barrier against EMI, thus protecting sensitive components and ensuring reliable signal transmission. Another important application of steel wire mesh in the telecommunications manufacturing industry is in antenna manufacturing. Antennas are crucial for transmitting and receiving signals in the telecommunications field. Steel wire mesh is used as a structural support for antenna systems, providing stability and durability. It helps to maintain the desired shape and alignment of the antennas, ensuring optimal signal strength and coverage. Moreover, steel wire mesh is also utilized in the construction of equipment racks and enclosures. These racks and enclosures are used to house various telecommunications equipment, such as servers, switches, and routers. Steel wire mesh provides a sturdy and secure framework for these structures, allowing for efficient installation and easy access to the equipment for maintenance and repairs. In summary, steel wire mesh plays a vital role in the telecommunications manufacturing industry. It is used for cable management, shielding against EMI, supporting antenna systems, and constructing equipment racks and enclosures. Its versatility, durability, and reliability make it an essential component in the telecommunications industry, ensuring the smooth operation and reliable performance of telecommunications equipment.

- Q:What is the maximum temperature steel wire mesh can withstand?

- The maximum temperature that steel wire mesh can withstand depends on the specific type and grade of the steel used. However, generally speaking, stainless steel wire mesh can withstand temperatures of up to 800-900 degrees Celsius (1472-1652 degrees Fahrenheit).

- Q:What are the benefits of using steel wire mesh in the transportation industry?

- Steel wire mesh has several benefits in the transportation industry. Firstly, it provides enhanced security by preventing unauthorized access to sensitive areas while maintaining visibility. Secondly, it offers durability and strength, making it suitable for applications such as cargo containment and reinforcement of structures. Additionally, steel wire mesh is resistant to corrosion, which is beneficial for transportation systems exposed to harsh weather conditions or corrosive materials. Lastly, its versatility allows for customization and easy installation, making it an ideal choice for various transportation applications.

- Q:How is steel wire mesh used in the agriculture industry?

- The agriculture industry extensively employs steel wire mesh for various purposes. Fencing and enclosures are one of its primary applications. Steel wire mesh is frequently used to establish boundaries, safeguard crops and livestock, and prevent unwanted animals from trespassing into agricultural areas. Its robust and long-lasting nature ensures its resilience against the elements, providing reliable security. In addition, steel wire mesh finds significant use in plant support within agriculture. Gardeners and farmers often rely on wire mesh to construct trellises, cages, and supports for climbing plants like tomatoes, beans, and cucumbers. This aids in maintaining the plants' structure, preventing them from toppling over, and facilitating better air circulation and sunlight exposure. Consequently, this results in healthier crops with higher yields. Steel wire mesh is also commonly employed in constructing animal enclosures and cages. It finds frequent utilization in poultry and livestock farming, enabling the creation of secure and safe enclosures for animals. This prevents them from wandering off or becoming prey to predators. By adjusting the mesh spacing according to the animals' size and type, their well-being and safety are ensured. Furthermore, steel wire mesh plays a vital role in the manufacture of beekeeping equipment. It is used to construct bee hives and frames, providing a sturdy structure for the bees to construct their combs and store honey. The mesh's small openings allow for proper ventilation while effectively preventing the bees from escaping. To summarize, steel wire mesh is an indispensable component within the agriculture industry. Its versatility, strength, and durability make it the ideal material for fencing, plant support, animal enclosures, and beekeeping equipment. By providing essential security and support, it significantly contributes to the overall success and productivity of agricultural operations.

- Q:Can steel wire mesh be used for light diffusers?

- Yes, steel wire mesh can be used for light diffusers. Steel wire mesh is versatile and can be woven or welded to create different patterns and densities. When used as a light diffuser, the steel wire mesh scatters and diffuses light, creating a softer and more even illumination. This makes it suitable for various applications such as architectural lighting, decorative lighting, and even in photography studios. The use of steel wire mesh as a light diffuser provides a unique aesthetic appeal while also serving a functional purpose.

- Q:Can steel wire mesh be powder coated?

- Indeed, it is possible to powder coat steel wire mesh. Powder coating involves the application of a dry powder paint onto the mesh's surface. To guarantee a secure bond between the powder coating and the mesh, the latter is initially cleaned and pre-treated. Subsequently, an even application of the powder is achieved by electrostatically charging the mesh and distributing the powder uniformly. Upon heating, the powder melts and creates a robust and protective coating. The popularity of powder coating for steel wire mesh stems from its remarkable corrosion resistance, durability, and the availability of a diverse color palette.

- Q:Can steel wire mesh be used for creating gabion baskets?

- Yes, steel wire mesh can be used for creating gabion baskets. Gabion baskets are typically made from steel wire mesh panels that are assembled and filled with stones or other materials. The wire mesh provides strength and stability to the basket structure, allowing it to withstand the forces exerted by the fill material and provide erosion control or retaining capabilities.

- Q:How does steel wire mesh perform in terms of resistance to chemicals?

- The resistance of steel wire mesh to chemicals is generally satisfactory. Steel possesses inherent properties, such as its strength and durability, that render it resistant to numerous chemicals. Nevertheless, the performance of steel wire mesh may differ depending on the specific chemicals it encounters. In most cases, steel wire mesh can withstand exposure to acids, alkalis, and solvents. It can endure the presence of common chemicals typically found in industrial and commercial settings without experiencing significant deterioration. This resistance to chemicals enables steel wire mesh to be utilized in various applications, including filtration, separation, reinforcement, and containment. However, it is crucial to acknowledge that certain chemicals can still inflict corrosion or damage upon steel wire mesh over time. Strong acids or highly corrosive substances have the potential to cause pitting or surface deterioration, which compromises the structural integrity of the mesh. Furthermore, prolonged exposure to specific chemicals can result in discoloration or staining of the steel wire mesh. To enhance the performance and durability of steel wire mesh when placed in chemical environments, it is advisable to utilize stainless steel wire mesh. Stainless steel incorporates additional alloying elements, such as chromium and nickel, that provide superior resistance to corrosion and chemical attack. This type of steel wire mesh is particularly suitable for applications where it will encounter aggressive chemicals or high levels of humidity. In conclusion, steel wire mesh generally exhibits commendable resistance to chemicals, rendering it suitable for a wide array of applications. Nevertheless, the specific performance may vary based on the type and concentration of chemicals involved. By opting for stainless steel wire mesh and implementing proper maintenance and cleaning protocols, the resistance to chemicals can be further enhanced, ensuring optimal performance and longevity.

- Q:Is steel wire mesh resistant to radiation?

- Indeed, resistance to radiation is a characteristic possessed by steel wire mesh. Renowned for its exceptional strength and durability, steel exhibits the remarkable capability to obstruct or weaken diverse manifestations of radiation, encompassing electromagnetic radiation and ionizing radiation. Consequently, steel wire mesh emerges as a highly efficient substance for safeguarding against radiation within numerous contexts. Enhanced radiation protection is attainable through employment of steel wire mesh featuring augmented density and reduced mesh size. Nonetheless, it is crucial to acknowledge that the efficacy of steel wire mesh in thwarting radiation hinges upon the nature and potency of the radiation source.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Stainless Steel Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords