High Quality Quartz Crucible

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000pcs pc

- Supply Capability:

- 10000PIECE PER MONTH pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of High Quality Quartz Crucible

Packaging Detail: Inner White foam paper+ Plastic foam sheet ,Outside with carton

Delivery Detail: within 20 days after paying the deposit

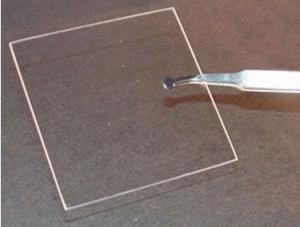

Specifications of High Quality Quartz Crucible

1. accept paypal quartz glass

2. we have 6 inch to 24 inch

2. we manufactuer

4. we provide samples

Applification of High Quality Quartz Crucible

quartz crucible | |

SIO2 : | 99.9 % |

Density : | 2.2(g/cm3) |

Degree of hardness moh' scale : | 6.6 |

Melting point: | 1732°C |

Working temperature : | 1100°C |

Max temperature can reach in a short time : | 1450°C |

Acid tolerance: | 30 times than Ceramics , 150 times than Stainless steel |

Visible light transmittance : | above 93% |

UV spectral region transmittance: | 80% |

Resistance value : | 10000 times than ordinary glass |

Annealing point: | 1180°C |

softening point: | 1630°C |

Strain point: | 1100°C |

Item | OD | H | Wall Thickness | R | r | ||

Size | W1 | W2 | W3 | ||||

10’’ | 254±2 | 190±3 | 6.0±1.5 | 6.0±1.5 | 6.0±1.5 | 305 | 60 |

12’’ | 305±2 | 229±3 | 7.0±1.5 | 7.0±1.5 | 7.0±1.5 | 305 | 80 |

14’’ | 355±2.5 | 280±3 | 8.0±2 | 8.0±2 | 8.0±2 | 400 | 90 |

16’’ | 406±2.5 | 280±3 | 8.5±2 | 8.5±2 | 8.5±2 | 406 | 90 |

18’’ | 457±3 | 320±3 | 9.0±2.5 | 9.0±2.5 | 9.0±2.5 | 500 | 120 |

20’’ | 505±3 | 350±3 | 11.0±2.5 | 11.0±2.5 | 11.0±2.5 | 508 | 90 |

22’’ | 558±4.5 | 381±3 | 11.0±3 | 11.0±3 | 11.0±3 | 558 | 110 |

24’’ | 610±5 | 381±3 | 11.0±3 | 11.0±3 | 11.0±3 | 610 | 90 |

- Q:External surface macular problem of arc type quartz crucible

- In order to solve this problem, you can start from two aspects: the 1 is the melting of sandblasting, cutting and transportation and storage process, do not touch the pollutants; such as dirty gloves, equipment oil, touch, dust, etc.. 2 is pickling. Hydrofluoric acid blister for a few minutes, rinse with deionized water, water resistivity is higher than 12 trillion, 14 or 16 better.

- Q:Is the quartz crucible drawn by monocrystalline silicon disposable?

- Yes, once a quartz crucible has been used, it will crack or break even after high temperature and cooling. And the single crystal drawing requires a high-purity quartz crucible.

- Q:A brief introduction to quartz crucibles

- Quartz crucible can be used below 1450 degrees. It is divided into two kinds: transparent and opaque. The translucent quartz crucible fabricated by arc method is the basic material for drawing large diameter monocrystalline silicon and developing large-scale integrated circuits. Today, the world's semiconductor industry developed countries have replaced the small transparent quartz crucible with this crucible. He has high purity and strong heat resistance, large size high precision, good heat insulation, energy saving, stable quality etc..

- Q:Can porcelain crucible, quartz crucible and alumina crucible be filled with aluminium hydroxide?

- Quartz glass crucible can be used below 1450 degrees. It is divided into two kinds: transparent and opaque

- Q:What are the main differences between the corundum crucible and the quartz crucible?

- Quartz crucible can be used below 1650 degrees. It is divided into two kinds: transparent and opaque. The translucent quartz crucible fabricated by arc method is a basic material for developing large scale integrated circuits. It has the advantages of high purity, strong heat resistance, large size, high precision, good heat insulation, energy saving, stable quality and so on;

- Q:What are the sizes of arc quartz crucibles?

- HF can not contact, high temperature, easy and caustic alkali carbonate reaction and alkali metal. 3. quartz crucibles are suitable for melting samples with K2S2O7, KHSO4 as flux, and using Na2S207 (first drying at 212 degrees) to treat samples with flux.

- Q:What crucible is used to melt solid caustic soda?Why not quartz crucibles?

- Iron. React with ceramic or glass silica ash

- Q:Why are fused quartz transparent and opaque?

- Quartz glass is a kind of special glass containing only single silica component. Because of the type of technology, raw materials, quartz glass, glass, often called foreign silicate quartz glass, fused silica, fused quartz, synthetic fused silica, and no clear concept of transparent, translucent, opaque quartz.

- Q:Can quartz crucibles be used as ROI for fluorine compounds?

- It has the advantages of high purity, strong heat resistance, large size, high precision, good heat insulation, energy saving, stable quality and so on; and not HF contact, high temperature, easy and caustic alkali carbonate reaction and alkali metal; quartz crucible suitable for K2S2O7, KHSO4 and Na2S207 as flux melted samples (the first in 212 the degree of drying) as flux sample; quartz brittle, easily broken, use caution; in addition to Hf, the ordinary dilute inorganic acid can be used as a cleaning fluid. Corundum crucible: corundum crucible is composed of porous fused alumina, hard and refractory; corundum crucible for melting flux samples with anhydrous Na2C03 and some alkaline substances, not suitable for use in Na 202 and NaOH strong alkaline substances and acidic substances as flux (as K2S 207) melt sample.

- Q:How to improve the quality of transparent layer of quartz crucible used for monocrystalline silicon

- In order to improve the quality of the transparent quartz crucible layer three: 1: use of raw materials, it is the monopoly of the uni quartz sand.2. vacuum arc furnace production method of vacuum and high pure health, it is important to you in one process pay attention to detail is no good.3., the production process and temperature, etc., these are the details of the process, such as temperature, cooling time ah...

1. Manufacturer Overview |

|

|---|---|

| Location | Guangdong,China |

| Year Established | 1999 |

| Annual Output Value | |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe |

| Company Certifications | ISO9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | |

Send your message to us

High Quality Quartz Crucible

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000pcs pc

- Supply Capability:

- 10000PIECE PER MONTH pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches