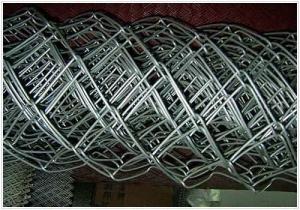

High Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q:What are the different opening configurations available for steel wire mesh?

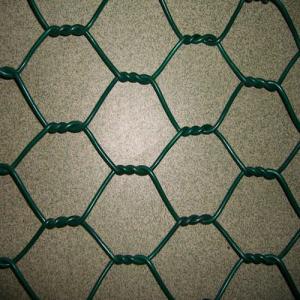

- Steel wire mesh offers a variety of opening configurations, each with its own distinct characteristics and applications. 1. The square opening, which is the most common and basic type, consists of wires intersecting at 90-degree angles to create square-shaped openings. It provides a well-balanced distribution of strength and flexibility, making it suitable for various applications such as filtration, screening, and reinforcement. 2. For situations requiring a higher percentage of open area, the rectangular opening is used. Similar to the square opening, it features longer and narrower rectangular-shaped openings. This configuration is commonly employed in architectural applications or for ventilation purposes. 3. The diamond opening configuration involves wires intersecting diagonally to form diamond-shaped openings. This configuration offers excellent strength and stability, making it ideal for heavy-duty applications like security fencing, machine guards, and partitions. 4. Hexagonal opening, also known as hex mesh or chicken wire, is characterized by hexagonal-shaped openings. It is commonly utilized in poultry enclosures, garden fencing, and erosion control due to its lightweight nature and ease of installation. 5. In the slotted opening configuration, the wires are arranged parallel to each other, resulting in elongated slots instead of traditional square or rectangular openings. This type of mesh is often employed in architectural applications where visual aesthetics and airflow are important factors. 6. Unlike woven wire mesh, expanded metal mesh is produced by cutting and stretching a flat sheet of metal, resulting in diamond-shaped openings with raised strands. This expanded metal opening configuration offers an excellent strength-to-weight ratio and is commonly utilized in platforms, walkways, and stairs. To determine the most suitable opening configuration for your steel wire mesh, it is essential to consider the specific requirements of your application, including strength, flexibility, visibility, and airflow.

- Q:How does steel wire mesh perform in terms of electrical conductivity?

- Steel wire mesh is generally not regarded as a proficient conductor of electricity. Despite being a metal and possessing some level of conductivity, the interweaving of multiple wires and the small size of the wires in a mesh significantly hinder the flow of electrical current. Consequently, the mesh acts as a resistor, obstructing the movement of electrons. Various factors, such as wire thickness, spacing, and the presence of coatings or impurities on the surface, also impact the electrical conductivity of steel wire mesh. These factors further reduce conductivity, rendering it less efficient for electrical conduction. Nonetheless, it is worth mentioning that steel wire mesh can still conduct electricity to some degree, particularly if the mesh is thick, the wires are closely spaced, or the surface is uncontaminated and devoid of any insulating substances. In specific applications like grounding or shielding, steel wire mesh can prove effective for conducting electrical current. In conclusion, although steel wire mesh possesses some electrical conductivity, it is generally not considered a good conductor due to its design and physical properties. It is important to consider the specific requirements of an electrical application before selecting steel wire mesh as a conductor.

- Q:Does steel wire mesh rust?

- Yes, steel wire mesh can rust. Rust is the result of the oxidation process that occurs when iron or steel is exposed to moisture and oxygen. If the steel wire mesh is not properly coated or protected, it can be susceptible to rusting over time. However, there are various methods to prevent or minimize rusting, such as galvanizing the steel wire mesh or applying a protective coating. These measures can significantly extend the lifespan of the mesh and ensure its durability.

- Q:What are the different wire diameters available in steel wire mesh?

- A variety of wire diameters are available for steel wire mesh to meet different needs and uses. Commonly found wire diameters in steel wire mesh include 0.5mm, 0.8mm, 1mm, 1.2mm, 1.5mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, and 6mm, among others. These diameters determine the thickness and strength of the wire used in the mesh. It is crucial to select the appropriate wire diameter as it directly impacts the durability, rigidity, and flexibility of the mesh. The choice of wire diameter depends on factors such as the intended use of the mesh, desired strength and stability, and required opening size. Thicker wire diameters are generally employed for heavy-duty applications that necessitate high strength and resistance, while thinner wire diameters are suitable for lighter applications that prioritize flexibility and smaller openings.

- Q:How is steel wire mesh used in reinforcement of stadiums and sports arenas?

- Steel wire mesh is an essential component in the reinforcement of stadiums and sports arenas due to its strength, durability, and versatility. It is commonly used in various applications within these structures to enhance their structural integrity and safety. One of the primary uses of steel wire mesh in stadium reinforcement is the construction of concrete slabs and walls. By embedding the mesh within the concrete, it provides additional tensile strength and prevents cracking or crumbling of the structure under heavy loads or external forces. This reinforcement ensures that the stadium or arena can withstand the weight of the spectators, equipment, and any other live loads during events. Moreover, steel wire mesh is extensively used in the creation of fencing systems around the perimeter of stadiums. These fences act as safety barriers, preventing unauthorized access to restricted areas and ensuring the protection of both spectators and the playing field. The mesh's strong and rigid nature makes it an ideal material for fencing, as it can withstand impacts from external forces while maintaining its structural integrity. In addition to concrete reinforcement and fencing, steel wire mesh is also utilized in the construction of staircases, walkways, and platforms within stadiums. These areas experience high foot traffic, and the mesh provides reinforcement to prevent any structural failures or accidents. By embedding the mesh within the concrete steps or walkways, it ensures the stability and longevity of these components, thereby ensuring the safety of the spectators. Furthermore, steel wire mesh is used in the reinforcement of roof structures in stadiums and arenas. These roofs are often large and span wide areas, requiring additional support to withstand wind loads and other environmental forces. The mesh is integrated into the roof structure to provide reinforcement and prevent any potential sagging or collapse, ensuring the safety of the spectators below. Overall, steel wire mesh plays a vital role in the reinforcement of stadiums and sports arenas. Its strength, durability, and versatility make it an ideal material for various applications such as concrete reinforcement, fencing, staircases, walkways, platforms, and roofs. By incorporating steel wire mesh into these structures, stadiums and sports arenas can ensure the safety, stability, and longevity of their facilities, providing a secure and enjoyable experience for spectators and athletes alike.

- Q:What is the principle of screen printing?

- Screen printing is the need to print the text / image through the sensor in the silk (now chemical fiber, mainly polyester fiber) online screen.

- Q:Is steel wire mesh resistant to animal bites?

- Steel wire mesh generally offers resistance against animal bites. The wire mesh's strength and durability make it challenging for most animals to chew through or harm. However, it's important to consider the size and strength of the animal as well. Thinner gauges of steel wire mesh may still be vulnerable to chewing by small animals like rodents or rabbits, or they may find alternative ways to access the desired area. Moreover, determined large and powerful animals like bears or large dogs might be capable of damaging or breaking through steel wire mesh. Consequently, although steel wire mesh provides a higher level of resistance to animal bites compared to other materials, it is not entirely impervious. It should be selected based on the specific animal threats that exist.

- Q:Can steel wire mesh be used as a reinforcement in soil?

- Yes, steel wire mesh can be used as a reinforcement in soil. It is commonly used in geotechnical engineering applications to provide additional strength and stability to soil structures. The steel wire mesh is typically placed within the soil mass to increase its tensile and shear strength, prevent erosion, and improve the overall stability of the soil. It can be particularly useful in areas with poor soil conditions or where there is a need for additional reinforcement due to heavy loads or vibrations. The steel wire mesh acts as a reinforcement element, distributing the applied loads and reducing the potential for soil movements and failures. Additionally, the use of steel wire mesh as a reinforcement in soil can also enhance the longevity and durability of the soil structure.

- Q:What are the different mesh configurations available for steel wire mesh?

- There are several different mesh configurations available for steel wire mesh, each designed to cater to specific applications and requirements. Some of the common mesh configurations include: 1. Square Mesh: This is the most basic and widely used mesh configuration, where the wires are woven together in a square pattern, forming equal-sized square openings. It offers good strength and stability. 2. Rectangular Mesh: Similar to square mesh, but with rectangular openings. This configuration provides greater flexibility and is often used in applications where a higher flow rate or larger particle retention is required. 3. Dutch Weave Mesh: In this configuration, the warp wires (running lengthwise) are smaller in diameter than the weft wires (running widthwise). This creates a tighter weave with smaller openings, giving it excellent filtration capabilities for fine particles. 4. Twilled Weave Mesh: It is a variation of the plain square weave, where the weft wires pass over and under two warp wires instead of one. This configuration creates a diagonal pattern, resulting in a stronger mesh with higher tensile strength. 5. Reverse Dutch Weave Mesh: This configuration is the opposite of the Dutch weave mesh, where the warp wires are larger in diameter than the weft wires. It is commonly used for high-pressure filtration applications as it offers exceptional strength and filtration efficiency. 6. Welded Mesh: Unlike woven mesh, welded mesh is created by spot welding the intersecting wires together. This configuration offers high strength and durability and is often used for industrial applications such as fencing, reinforcement, and concrete reinforcement. 7. Expanded Metal Mesh: This configuration is made by cutting and stretching a sheet of metal, creating diamond-shaped openings with raised strands. Expanded metal mesh provides excellent ventilation, visibility, and is commonly used for security applications, architectural purposes, and grating. These are just a few examples of the various mesh configurations available for steel wire mesh. The choice of configuration depends on factors such as the intended application, required strength, filtration needs, and aesthetic preferences.

- Q:How is steel wire mesh used in slope stabilization?

- Due to its strength and durability, steel wire mesh is frequently utilized in slope stabilization projects. It functions as a reinforcing material that aids in the prevention of soil erosion and slope failures. When employed for slope stabilization, steel wire mesh is commonly installed in layers or grids across the slope surface. These mesh layers are securely anchored into the soil or rock using various techniques like soil nails or rock bolts. The mesh forms a physical barrier that effectively holds the soil or rock in place, preventing any downhill sliding or collapsing. The primary purpose of steel wire mesh in slope stabilization is to enhance the overall stability of the slope. It provides additional tensile strength to the soil or rock mass, particularly in areas where the natural stability of the slope is compromised. Additionally, the mesh helps to evenly distribute forces and stresses across the surface, thereby reducing the risk of localized failures. Moreover, steel wire mesh serves as a supportive system for vegetation growth. It can be utilized in conjunction with erosion control blankets or mats to facilitate the establishment of plants on the slope. The mesh offers a stable surface for plants to take root and flourish, thereby bolstering the overall stability of the slope through the reinforcement of the soil with their roots. In conclusion, steel wire mesh plays a vital role in slope stabilization by providing reinforcement, preventing soil erosion, and promoting vegetation growth. Its versatility and strength make it an indispensable component in engineering projects aimed at stabilizing and safeguarding slopes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords