Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

plastic granules:

Halogen Free Flame Retardant TPE Compound used for power cable

plastic granules: 1, Type and application: Used for Japanese standard power cable and electrical equipment cable

2, Introduction Environmental friendly halogen-free TPE cable compound, based on styrene elastomer, is made into granular by mixing, plasticization and granulation with special modifier, and other special additives. It has goodresilience, scratch-resistant and flexibility. The products meet various special requirements, such as different hardness, UV stable, fog surface and etc. This material, with exquisite and smooth appearance, has excellent performance of anti yellowing, weather resistant temperature resistance, without halogens, heavy metals, meeting the RoHS, REACH, and other environmental standards. 3, Processing: The compound can be processed with conventional extruders, and the screw with a minimum 25:1 L/D and a compression ratio of 2.5 is recommended. The following temperature(°C) profile of extruder is recommended: Note:Compound should be dried at 80-90°C before use, which has been stored more than one month. 4, Storage and transport Packaging:20kg/bag,Aluminum foil and PE film inside bag, and PP composite outside bag. Storage and transport: Avoiding in direct sunlight and weathering. The storage place should be clean, cool, dry, and ventilated. 5, Properties: |

Item | Unit | Typical | |||||||

E3685A | E3688B | E3690A | E3692A | E3692B | E3689A | ED3685 | EA3685 | ||

Density | g/cm3 | 1.11±0.03 | 1.09±0.03 | 1.14±0.03 | 1.08±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 | 1.10±0.03 |

Hardness | Shore A | 85±3 | 88±3 | 90±3 | 92±3 | 92±3 | 89±3 | 85±3 | 85±3 |

Melt Index 230℃×5kg | g/10min | 1.2 | 2.6 | 1.1 | 1.0 | 0.8 | 1.5 | 1.3 | 2.0 |

Tensile Strength | MPa | 15 | 12 | 13 | 16 | 13 | 14 | 12 | 11 |

Elongation at Break | % | 280 | 260 | 250 | 270 | 260 | 260 | 240 | 300 |

Thermal aging | ℃*h | 136℃*168h | |||||||

TS retention | ≥75% | 97 | 99 | 101 | 102 | 101 | 97 | 99 | 109 |

EB retention | ≥75% | 83 | 81 | 79 | 82 | 80 | 81 | 82 | 78 |

Hot deformation | ℃*h | 150℃*1h | |||||||

Variation | ≤50% | 15 | 13 | 12 | 8 | 6 | 9 | 7 | 38 |

pH of gases evolued | -- | 6.3 | 6.5 | 5.3 | 5.6 | 6.2 | 5.6 | 5.5 | 5.3 |

Conductivity of Gases evolved | ≤μm/mm | 1.4 | 1.3 | 1.5 | 1.2 | 1.1 | 1.2 | 1.0 | 1.3 |

Oxygen index | O2 % | 26 | 27 | 27 | 27 | 26 | 27 | 27 | 27 |

Impact Brittleness Temperature | -60 ℃ | Pass | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

Volume Resistivity, at 20℃ | Ω﹒m | 3.7×1014 | 3.5×1014 | 4.3×1014 | 3.5×1014 | 3.2×1014 | 4.1×1014 | 4.3×1014 | 5.4×1014 |

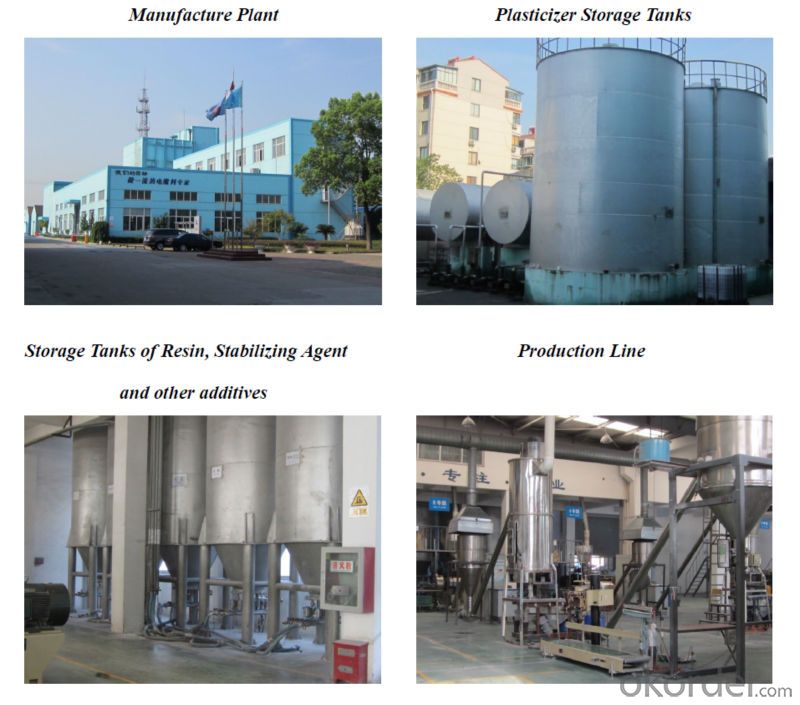

6. Company

- Q:What is the plastic bag made of?

- The main raw material of plastics is oil and natural gas, that is, carbon hydrogen compounds. First, the appropriate macromolecular components in petroleum and natural gas are extracted, first split into monomers, and then polymerized into polymers to become plastic

- Q:What are plastic materials extracted from?

- All kinds of plastics are gradually processed to produce various kinds of downstream products, including rubber, coating, finishing agent, artificial fiber, synthetic resin and so on.Resin usually refers to softening or melting range after heating. When softening, it tends to flow under external force. At normal temperature, it is solid, semi solid, and sometimes liquid organic polymer.

- Q:How many kinds of raw materials are produced by wrapping plastic film?

- Plastic film raw materials are: PVC, polyethylene, polypropylene, polystyrene and other resins.Commonly used to bundle packaging is LLDPE stretch wrap film, applicable to a variety of logistics packaging, packaging industry bundled! I can see it in Ming Bao. Yes, please!

- Q:What are the heavy bags in the plastic material?

- (polypropylene) English Name: Polypropylene, PP plastic concept, proportion polypropylene, also includes propylene and a small amount of ethylene copolymer. PP granular material is natural, cylindrical particles, smooth particles

- Q:What are the common raw materials used in plastic bottles? What are the main features?

- PC bottles are transparent, shock resistant and high temperature resistant. They are expensive. 5 gallon pure water bottles are used at most. They can be sterilized by high temperature steam.The key depends on what you want to install, there is no corrosive, appearance requirements, and so on, decided to use what materials.

- Q:Raw materials for making plastic bags

- Polyethylene (Polyethylene, PE), referred to as PE. It is a high molecular organic compound which is made up of ethylene. Polyethylene is recognized as the best food for contact with food in the world. Non-toxic, tasteless, odorless, in line with food packaging hygiene standards. Polyethylene film, light and transparent, with moisture-proof, anti - oxygen, acid, alkali, air tightness, heat sealing and other outstanding performance. Known as "plastic flower" laudatory title. It is the most important and most important material in plastic packaging and printing.

- Q:What are the materials for making plastic basins? Are they raw materials?

- The plastic washbasin is made of PP plastic(polypropylene is a thermoplastic resin made by the polymerization of propylene.)Is a relatively traditional washbasin, anti wrestling performance is very strong.Although the modern bathroom, a variety of shapes, materials, fashion basin are,But still can not do without this traditional plastic basin.

- Q:What are the main biodegradable plastic bags made of?

- The degradable plastic bags made of polyethylene and starch, but this can only be degradable plastic plastic degradation into smaller chunks of plastic, plastic compositions did not completely disappear, so its degradation is limited.

- Q:What is the disposable transparent plastic cup?

- PC: colorless transparent material, suitable for making instruments, small parts, insulation, transparent parts and impact parts.Transparent ABS, this material is expensive, in the field of decoration, packaging and other promising.

- Q:Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- The so-called plastic raw material electroplating grade means that the particle of the plastic material is high in purity and high in polarity, and is easy to be evenly adhered to the metal particles before the plating.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Halogen Free Flame Retardant Thermoplastic Elastomer Compound for Power Cable

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords