GBF series fluorine plastic lining pipeline pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.GBF series fluorine plastic lining pipeline pump descriptions

GBF series fluorine plastic lining pipeline pump is made by fluorine plastic hot melt molding process, with particularly strong corrosion resistance of the new pipeline centrifugal pump. This pump impeller and motor straight via stent, choose bellows outer container type mechanical seal, shaft seal is stable and reliable, intuitive easy to adjust, hydraulic performance is superior, the suction uniform, over-current components using fluorine plastic materials(PEP, PFA ) manufacturing, decay resistance performance excellence.

Corrosion resistance, heat resistance, not aging, smooth operation, low noise, high efficiency, easy maintenance, long life and other advantages, widely used in acid and alkali, oil, chemical industry, electrolysis, electroplating, pickling, aluminum foil, rare earth, medicine, dyes, pesticides, flue gas desulfurization and dust removal, food, pharmaceutical and synthetic fiber industries.

Applicable temperature: 60℃~+150℃

2. Model sense

Ex: 50GBF-30

-50:Nominal diameter of inlet and outlet (mm)

-GBF:Fiourine plastic lining pipeline pump

-30:Pump head (m)

3. Design features

- The pump flow components application fluorine plastic hot melt moulding process combined into a whole, high mechanical strength;

- Has excellent corrosion resistance performance, transmission of all kinds of corrosive medium, such as acid, alkali, oxidant and organic solvent without damage;

-The pump is vertical structure, inlet and outlet diameter are the same, and is located in the center of a unified online, easy installation, use of a small area, the motor add a rainproof cover can be used outdoors;

- The impeller and motor direct dive, short axial dimensions, compact structure, smooth operation, high transmission efficiency, low noise and vibration;

- Shaft seal installed PTFE corrugated pipe mechanical seal, sealed and reliable, intuitive, and according to the characteristics of the media to provide a variety of materials friction pair selection, and has a wide application range;

- The use of the maintenance is convenient, only need to remove the pump body and the connecting frame fastening nut can be disassembled the rest, no need to remove the dynamic pipeline.

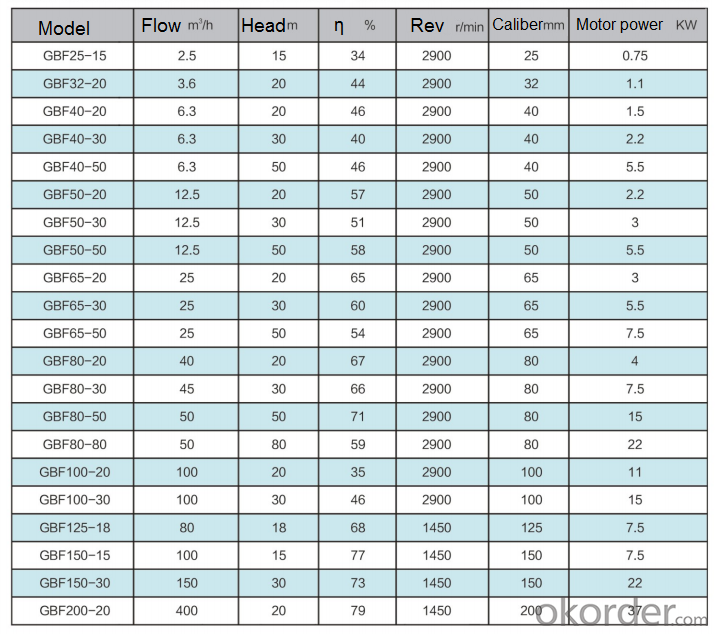

4. Technical parameters

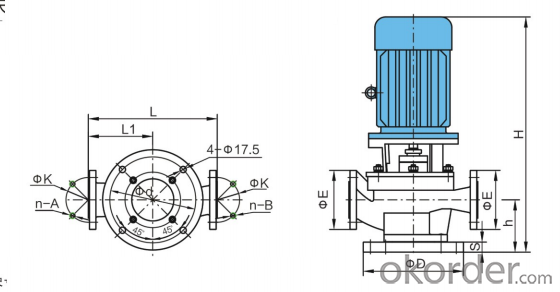

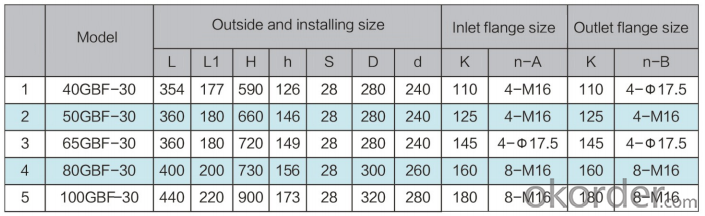

5. Install size / Flange size

- Q:What are the main performance parameters of the pump?

- RPM revolutions per minute. In N, the unit is R / minThe power delivered by the shaft power prime mover to the pump shaft. In P, the unit is kW.The ratio of useful power to shaft power of an efficient pump. With ETA said. It is an indicator of the degree of perfection of the pump in terms of hydraulic power

- Q:Bolus dosage of infusion pumpWhat is the purpose of the pill dose control in the special safety standard for infusion pumps? If the risk is not properly controlled, what is the degree of risk? And how can the open infusion pump be used in this regard?

- (three) infusion limited number of pills produced after the dose of obstruction by infusion pump and specification of the matching test, will reach acceptable when the storage pressure of the pressure to determine the alarm blocking. Thus, some have restrictions on the infusion tube blocked after the maximum dose pill may have blocked the trigger before the alarm.

- Q:Why can't the centrifugal pump pump the vacuum?

- Running process: depending on the centrifugal pressure of the liquid in the impeller, the liquid is sucked into the liquid, and the liquid in the pump shell has the conversion of the energy form, so that the fluid can obtain the mechanical energy mainly with the static pressure.The characteristics of the system: the suction diameter than out of large diameter, the general valve installed.

- Q:Significance of water pump model ISO50-160

- A pump is a machine that transports liquids or pumps liquids. It will be the prime mover of the mechanical energy or other external energy transfer to the liquid, the liquid energy increase, mainly used to transport liquids including water, oil, alkali liquid, emulsion, suspension emulsion and liquid metal, but also transport liquid, gas mixtures and liquids containing suspended solids. Pump performance parameters include flow, suction, lift, shaft power, water power, efficiency and so on;

- Q:The distance from the pump button to the ground

- Yellow warning pop-up, indicating that the fire control room has issued alarm information, fire alarm controller (commonly known as the alarm host)

- Q:Water pump outlet valve sequence

- In order to prevent the generation of water hammer when the pump stops the damage to the rubber head, should be immediately set rubber head pump outlet, the gate valve and the check valve is not a very convincing reason to decide the order of habits in our hospital order rubber head, check valve, gate valve1. Check valve located in front of the pump, I do not know what the significance is too great to think of.2. The actual installation sequence shall be: soft fittings, check valves, gate valves. The pressure gauge is best installed on the water outlet of the pump, but it must be in front of the check valve.Reason: 1) the soft joint is used to reduce vibration. The connection between the pump and the piping system, of course.2) normal work, the gate valve is not operating, and the check valve is frequent action, so the probability of maintenance is larger, when the maintenance of the pump closed, the water outlet valve can be maintained without affecting the normal operation of the system.3) the pressure gauge is installed in the check valve, which can prevent the impact and damage of water hammer on the pressure gauge.

- Q:The working principle of magnetic pump

- Control of cooling fluid flowThe pump is running, you must use a small amount of liquid in the magnetic separation between the rotor and the casing annulus area and sliding friction bearings for flushing cooling. The cooling liquid flow pump design flow is usually 2%-3%, the annular area between the magnetic rotor and sleeve of eddy current generated because of high heat. When the cooling and lubrication the liquid is not enough or poor flushing holes to plug, will result in permanent magnet medium temperature is higher than the operating temperature of the inner magnetic rotor gradually loses magnetism, the magnetic actuator failure. When the medium is water or water-based liquid, can make the annulus area temperature maintained at 3-5 DEG C; when the medium or hydrocarbon oil that can make the annulus area temperature maintained at 5-8 degrees.

- Q:Suction stroke and lift of water pump

- Lift pump lift pump can lift refers to the height, usually expressed in H, the unit is m. centrifugal pump lift to the impeller center line, divided by two parts. The vertical height from the pump impeller centerline to the water surface, the water pump to suck water up to the height, called water head, referred to as suction pump impeller; from the center line to the vertical height of the water tank, the water pump can put pressure on the height, called water pressure head, referred to as the pressure. The pump head = + suction head pressure water head should be pointed out that the nameplate marked head refers to the pump itself can produce lift, it is not with the pipe flow friction resistance caused by the loss of lift. In the selection of water pump, attention can not be ignored. Otherwise, will be pumping Sheung Shui.

- Q:What is the main difference between SK water ring vacuum pump and 2BV water ring vacuum pump?

- SK vacuum pump is a single-stage water ring vacuum pump, vacuum pump and motor separation, coupled with couplings, vacuum relatively low.

- Q:Do you have a suction pump higher than 9 meters?

- Pump rated suction generally 7 meters or so, it is estimated that no one calibration pump suction stroke 9 meters. Calibration suction range of 9 meters is not reliable.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GBF series fluorine plastic lining pipeline pump

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords