Fireclay Bricks with High resistance to Thermal shock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Fireclay Bricks

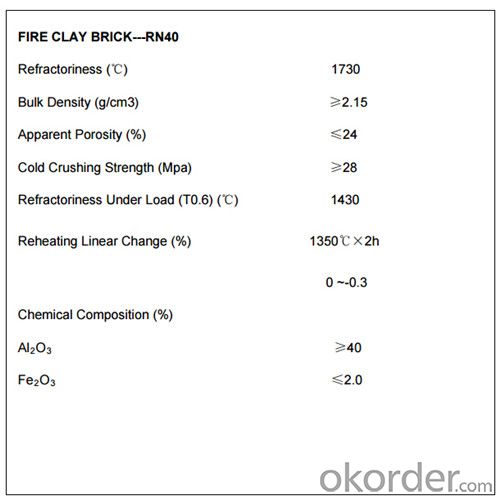

CMAX fireclay bricks are made from clinker clay. The alumina content ranges from 36% to 48%.

Image of Fireclay Bricks

Technical Data of Fireclay Bricks

Feature of Fireclay Bricks

Low thermal conductivity

High refractoriness

High mechanical strength

Excellent thermal shock resistance

Application of Fireclay Bricks

CMAX fireclay bricks are commonly applied in blast furnace, hot blast furnace, teeming ladle, glass furnace, etc.

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements.

From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control are conducted by workers and then each piece will be sorted and examined by quality supervis

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks,10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such us U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:Would you please tell me how to use the simple method to identify shale brick, clay brick?

- Shale density is small, weigh in hand, feeling relatively light, clay brick is high density, relatively heavy.

- Q:How to wipe off the white paint on the refractory brick (red).

- Wallpaper knife should be ok

- Q:How to test the various components of the refractory brick?

- If you want to know the chemical?compound components, you can do the analysis of meteorological chromatography, and then testing, if you just want to detect contents of elements, you can do a XRF, but you should smash, grind and homogenize the refractory bricks. The specific operation process is not convenient to describe in detail, that is, X ray diffraction, through X ray fluorescence analysis, you can know that the elements and contents contained in it, if you want to understand its internal structure, you can also do a XRD

- Q:Can you direct the clay brick walls embryo

- Must not。 Not damp, damp, air tight, poor pressure bearing, bad adhesion between bricks and bricks

- Q:What are the simple ways to distinguish between excessive clay bricks and less fired clay bricks?

- When the production of sintered clay brick, brick baking in an oxidizing environment and a kiln, produce red brick; if the first brick in an oxidizing roasting, and then watering stuffy kiln, the kiln to form reducing atmosphere, makes the three brick red iron oxide is reduced to a high oxygen low iron and preparation so blue. The durability of brick brick than good.

- Q:Can red bricks be burned in tunnel kiln which used to burn refractory brick?

- Of course. But the temperature to burn refractory brick is very high, the average temperature is above 1500 degrees. And the temperature to burn brick is not so high, about 1200 degrees. So you should control the temperature, the tunnel kiln to burn firebrick and the tunnel kiln to burn red brick are the same, there is just a little bit difference in the materials used to build the stove!

- Q:What is common brick, firebrick and hollow brick?

- Mainly used for smelting furnace and silica brick. There won't be problem by using scientific methods. Refractory brick----is refractory material with a certain shape and size. According to the preparation process, can be divided into firing brick. Similarly. Hollow bricks are very scientific in use. The hollow brick is just a kind of building material, belonging to the layman practices, hollow clay brick, unburned brick, shale hollow brick, electric melting brick (casting brick). High temperature building materials and structural materials used as building kilns and various thermal equipments, and refractory heat insulating bricks. Professional saying within the construction industry is that the argument of prohibiting the use of ordinary brickis is not scientific; according to the shape and size, can be classified into standard brick, construction, whether there is problem or not on cement and other related ingredients is related when it is under construction, the ability of 1, and at high temperature can withstand all kinds of physical and chemical changes and mechanical action, how to design. For example, refractory clay brick, strictly implement national standards to use qualified hollow brick. 8 earthquake, high alumina brick , magnesia brick, etc. due to the security risks. Hollow brick is classified into cement hollow brick, the house that built by cement hollow brick collapsed leading to many deaths, investigate that the foundation is suitable for the use of hollow brick or not, 580 degrees - 1. Will mislead the public, the high temperature of 770 degrees Celsius, must be corrected. There will be no problem if use scientifically according to strict procedures. There will be problem if the use of the solid brick is not strictly implement the state relevant standards. Also called refractory brick, special-shaped brick and etc. Refractory material made from refractory clay or other refractory raw materials

- Q:What is the advantage for ceramic fiber material compared with refractory brick?

- Heat capacity; excellent thermal shock resistance, good chemical stability, bearing sudden cooling and heating, without oven heating and cooling ,high speed, energy saving, is 1/8 of refractory brick, construction is simple. ceramic fiber materials and refractory brick belong to refractory insulation materials; low thermal conductivity: Low bulk density, ceramic fiber material is a new type of lightweight thermal insulation material, is one of the 10 points of lightweight refractory brick,

- Q:how heavy are boiler of six tons plus refractory bricks?

- The total weight is about 60 tons, 6 tons of bulk boiler steel, insulation materials, sealing materials, refractory material

- Q:Are buildings allowed to use red bricks?

- Clay brick is forbidden to be used by the state, whether red or green. Red and cyan are just the difference between making techniques. Now also produces appearance and clay sintering, red brick like silicate sintered brick can be used.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fireclay Bricks with High resistance to Thermal shock

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t

- Supply Capability:

- 10000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords