Fiberglass Roofing Panels(Sheets) for Constructin Using

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Roofing Panels(Sheets) for Constructin Using

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. The intensity and stiffness is quite prominent,.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. Corrosion resistance no rust, no maintenance, long service life.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

- High strength.

Easy to maintain.

Long service life.

Easy to install.

Good light transmittance.

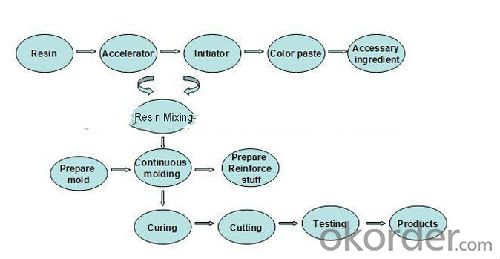

Production Process

Specification&Technical Parameters

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: Would you like to let us get your sampels?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q:What are the different thicknesses of fiberglass fabric available?

- The thicknesses of fiberglass fabric can vary, but common options include 0.5 oz, 1 oz, 1.5 oz, 2 oz, and 3 oz per square yard.

- Q:Can fiberglass fabric be used for insulation in underground structures?

- Indeed, insulation in underground structures can be achieved by utilizing fiberglass fabric. This fabric is highly favored for its exceptional thermal characteristics and ability to withstand moisture. It is widely employed in numerous applications, notably in underground structures like basements, tunnels, and underground storage facilities. Typically, the fabric is positioned as a layer between the structure's walls or ceiling and its interior finish, serving as a protective barrier that curbs heat loss or gain and promotes a pleasant temperature within the structure. Moreover, fiberglass fabric is renowned for its lightweight nature, flexibility, and simplicity of installation, rendering it a convenient choice for insulating subterranean spaces.

- Q:Is fiberglass fabric resistant to fading?

- Indeed, fading does not affect fiberglass fabric as it boasts remarkable resistance. Fiberglass, an artificial substance composed of delicate glass fibers, exhibits high endurance against fading as a result of sunlight exposure. These fibers are frequently coated with a protective layer, bolstering their ability to withstand fading. Furthermore, fiberglass fabric also displays resistance towards numerous chemicals and does not readily deteriorate over time, rendering it an enduring and enduring choice for a wide array of applications.

- Q:How do fiberglass fabrics perform in terms of breathability for human comfort?

- Fiberglass fabrics are not particularly breathable and may not provide optimal comfort for humans.

- Q:Is fiberglass fabric resistant to chemicals in wastewater treatment?

- Fiberglass fabric, in general, exhibits resistance to chemicals commonly found in wastewater treatment. Its exceptional resistance to a wide range of chemicals, such as acids, alkalis, solvents, and other corrosive substances, is well-known. This resistance makes fiberglass fabric an ideal choice for various applications in wastewater treatment, including filtration, tank lining, and ductwork. Furthermore, fiberglass fabric's durability and longevity are enhanced by its resistance to UV radiation, high temperatures, and mechanical stress. However, it is crucial to acknowledge that the resistance of fiberglass fabric may vary depending on the chemicals' type and concentration in the wastewater. To ensure the suitability of the chosen fiberglass fabric for the specific chemical conditions of the wastewater treatment system, it is advisable to consult manufacturers or industry experts.

- Q:How does fiberglass fabric perform in electromagnetic fields?

- Known for its effectiveness in electromagnetic fields, fiberglass fabric possesses a non-conductive property that enables it to act as a reliable barrier against electromagnetic interference (EMI). When exposed to electromagnetic fields, fiberglass fabric does not absorb or conduct the waves, but rather reflects and disperses them, effectively preventing their penetration through the material. This outstanding characteristic makes fiberglass fabric an ideal choice for various applications requiring protection against EMI, such as in electronic devices, communication equipment, and aerospace applications. Moreover, fiberglass fabric exhibits a remarkable dielectric strength, allowing it to withstand high voltage without succumbing to breakdown or conductivity. As a result, it is well-suited for applications involving high electrical potential, including insulation in electrical cables or transformers. In conclusion, fiberglass fabric excels in electromagnetic fields by proficiently blocking and dispersing electromagnetic waves, while also providing exceptional dielectric strength. Its non-conductive nature and ability to endure high voltage position it as the preferred option for EMI shielding and electrical insulation applications.

- Q:How does fiberglass fabric perform in saltwater environments?

- Due to its inherent properties, fiberglass fabric performs exceptionally well in saltwater environments. Its resistance to corrosion makes it an ideal choice for applications that involve exposure to saltwater. Furthermore, fiberglass is unaffected by UV rays, ensuring that it does not degrade or weaken when exposed to sunlight in marine environments. In addition to this, fiberglass fabric offers an excellent strength-to-weight ratio, providing durability and longevity even in harsh saltwater conditions. It is also worth noting that fiberglass fabric does not absorb water, preventing it from becoming heavy or weakening over time. In conclusion, fiberglass fabric is a dependable and efficient material for use in saltwater environments, making it the preferred choice for applications such as boat building, marine repairs, and other water-related industries.

- Q:Can fiberglass fabric be used for reinforcing plaster or stucco?

- Fiberglass fabric, when used for reinforcing plaster or stucco, can significantly enhance the strength and stability of the surfaces. This durable and robust material is commonly employed in construction projects to prevent cracks and bolster the overall durability of plaster or stucco. Typically, the fiberglass fabric is applied to the surface prior to the application of plaster or stucco, ensuring an even distribution of stress and minimizing the likelihood of cracking or crumbling. Moreover, fiberglass fabric possesses resistance against both moisture and weathering, rendering it an ideal choice for exterior applications, where plaster or stucco may face harsh environmental conditions. Ultimately, the utilization of fiberglass fabric in reinforcing plaster or stucco contributes to the improved structural integrity and longevity of the final surfaces.

- Q:Are there any limitations or drawbacks to using fiberglass fabrics?

- Yes, there are certain limitations and drawbacks to using fiberglass fabrics. Firstly, fiberglass fabrics can be relatively expensive compared to other fabric options. Additionally, working with fiberglass fabrics requires specialized equipment and expertise, making it more challenging for DIY or inexperienced users. Furthermore, fiberglass fabrics can be brittle and prone to cracking or breaking under excessive stress or impact. Finally, fiberglass fabrics may have limited flexibility, making them less suitable for applications that require a high degree of flexibility or stretchability.

- Q:How is fiberglass fabric used in insulation?

- Fiberglass fabric is commonly used in insulation due to its excellent thermal properties. It is primarily used in two main forms: batts and loose-fill insulation. In the case of fiberglass batts, the fabric is woven into sheets, which are then cut to fit between the studs, joists, and beams of buildings. These batts are typically installed in walls, ceilings, and floors to provide a barrier against heat transfer. The fiberglass fabric helps to trap air within its fibers, creating pockets of still air that significantly reduce the conduction of heat. This process, known as thermal insulation, helps to maintain a comfortable indoor temperature and reduce energy consumption by minimizing the need for heating and cooling. Another application of fiberglass fabric in insulation is loose-fill insulation. In this form, the fabric is processed into tiny fibers and blown or poured into walls, attics, and other enclosed spaces. The fabric fibers intertwine, creating a dense layer that acts as a thermal barrier. Loose-fill insulation is particularly effective in filling irregularly shaped or hard-to-reach spaces, ensuring that there are no gaps or voids where heat can escape or enter the building. Fiberglass fabric is also used in combination with other materials to enhance insulation performance. For example, it is often combined with foam or foil to create rigid panels or reflective insulation. These composite materials provide additional benefits such as moisture resistance, soundproofing, and enhanced thermal resistance. In summary, fiberglass fabric is used in insulation to minimize heat transfer, improve energy efficiency, and create a comfortable indoor environment. Whether in the form of batts or loose-fill, fiberglass fabric acts as a thermal barrier, reducing the conduction of heat and enhancing the insulation properties of buildings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Roofing Panels(Sheets) for Constructin Using

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords