Fiber Cement Board Cement Board Hot Sale Asbesto Free

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

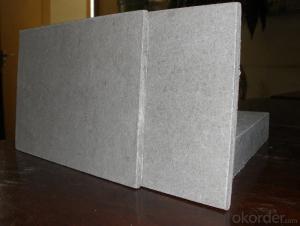

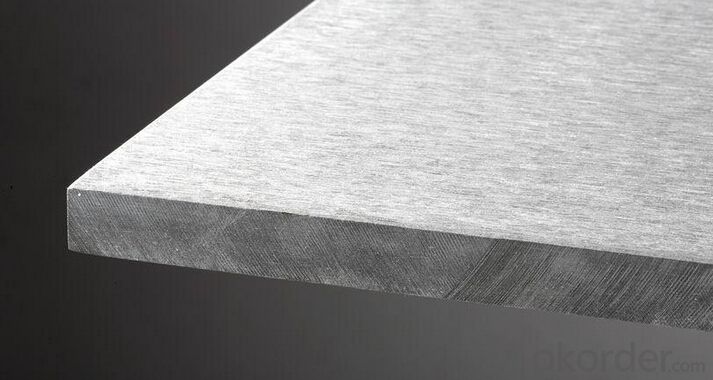

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

Images:

- Q: how do you join cement board from a shower wall to drywall?

- Other than being nailed to the same stud, it is not all that necessary that they be joined together. Just figure on the tile overlapping the drywall about a half an inch to kill the crack. You can mesh tape them together however and skim them flat with each other as long as you don't skim wide into the tile board area. You could do as little as just caulk the crack with silicone too.

- Q: Directly on the cement board to brush the glass can you!

- 1, cleaning Before cleaning the paint must be a good cleaning, because there is dust, then paint effect is not good. 2, tools Paint the need to paint the roller, find a dilapidated washbasin to paint. 3, tune paint Bought the paint because the viscosity is too high need dilute dilution, before painting in accordance with the proportion of deployment.

- Q: There is a problem like your team to ask the partition wall have what form in addition to light steel keel gypsum board there are no other

- You can choose light steel keel plus fire board, fire board, including glass magnesium board, calcium silicate board, fiber cement board

- Q: Do you know that light through the cement? What is the material and how to do it?

- Litracon is a widely used new building material with light transmission properties. It is a compound of fiber and fine grinding cement that can be used to produce construction and installation of prefabricated blocks and cement boards. As the fiber size is small, so as a new ingredient mixed with the cement together to form a collection. Therefore, the final not only in the cement is mixed with two components of glass fiber only, but in the internal structure and the surface can achieve a balanced effect of new building materials. From thousands of optical fibers in parallel between the two sides of the cement block to form a policy. The proportion of fibers is very low (4%) throughout the cement block. In addition, because the fiber size is very small, so become a cement structure of a collection of components, cement block surface or uniform cement. In theory, the light-permeable cement block can be built with a few meters of thickness of the wall, because the fiber in principle, within 20 meters will not lose any light information. The fiber does not affect the high capacity of the cement, so in these cement blocks can build any load of the building structure. The light-permeable cement block can be produced in a different size, and a heat-insulating layer can be added thereto.

- Q: What are the standards for residential steel structures?

- Steel structure residential system is composed of the envelope structure and steel support structure of the common residential system, is the province of energy-saving new residential system. It is the steel structure of the house to abandon the solid clay brick, the effective use of land resources. Steel residential buildings have advantages in terms of functional, design, construction and integrated economy compared to traditional homes

- Q: What are the differences between the gypsum board and the cement pressure plate and the Eide board?

- Cement pressure plate is based on natural fibers and cement as raw material, by the pulp, forming, cutting, pressing Steamed into a new type of building plate. With light, high strength, waterproof, anti-corrosion, fire, large format, good processing, improve construction efficiency and so on. Mainly used for internal and external walls, pouring walls, composite panel wall panels, fire door lining, external wall insulation panels.

- Q: Will the decoration of the cement board with the kind of thin how many species

- Natural wood fiber products are selected from 2 to 3 years old natural pollution-free Australian fast-growing trees, crushed high-temperature cooking into wood pulp extracted fiber. Through special technology and production process to remove the sugar and fat in wood, and the use of advanced technology to eliminate the electrostatic reaction of substances. The whole process without any chemical ingredients, and cotton are 100% green products. With a natural antibacterial health care, remove the smell, self-cleaning function, soft touch, not hardened, is a real, pure green health products.

- Q: Replacing the cement board is not realistic, I don't know of anything that may be more flexible and not deteriorate so quickly.

- there are some colored cement repair products that contain silicone that may work good, also you can just use white silicone or caulk just squeeze it in and let it dry have a rag handy for cleanup both are flexible and last a long time.

- Q: How durable and lasting is the concrete board that is installed on homes? IS it true that it doesn;t need painted for at least 15 years?Thank you

- it can last even longer depending on exposer to weather, feild painted or factory painted. hardi plank or certinteed cement board are both good products. the main thing is to keep the back side of the board ( keep n eye on your caullking ) if moisture can wick threw the board , the paint will start to fail and peel.

- Q: are you able to mountain board not only on dirt but also on surfaces like cement, for ex: a street?

- you probably could

Send your message to us

Fiber Cement Board Cement Board Hot Sale Asbesto Free

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords