FC90-95 Recarburizer -Low Sulphur and low P

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

25kgs/50kgs/1ton per bag or as buyer's request

Specifications

Calcined Anthracite

Fixed carbon: 90%-95%

S: 0.5% max

Size: 0-3. 3-5.3-15 or as request

It used the high quality anthracite as raw materials through high temperature calcined at over 2000 by the DC electric calciner with results in eliminating the moisture and volatile matter from anthracite efficiently, improving the density and the electric conductivity and strengthening the mechanical strength and anti-oxidation. It has good characteristics with low ash, low resistvity, low sulphur, high carbon and high density. It is the best material for high quality carbon products.

Advantage and competitive of caclined anthracite:

1. strong supply capability

2. fast transportation

3. lower and reasonable price for your reference

4.low sulphur, low ash

5.fixed carbon:95% -90%

6..sulphur:lower than 0.3%

General Specification of Calcined Anthracite:

| FC % | 95 | 94 | 93 | 92 | 90 |

| ASH % | 4 | 5 | 6 | 6.5 | 8.5 |

| V.M. % | 1 | 1 | 1 | 1.5 | 1.5 |

| S % | 0.3 | 0.3 | 0.3 | 0.35 | 0.35 |

| MOISTURE % | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

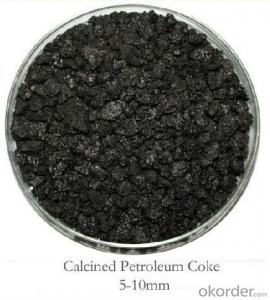

Pictures

- Q:How does carbon contribute to the hardness of steel?

- Carbon contributes to the hardness of steel by forming strong chemical bonds with iron atoms, which results in the formation of carbides. These carbides create obstacles to dislocation movement within the metal lattice, making it more difficult for atoms to shift and deform. As a result, the presence of carbon increases the strength and hardness of steel.

- Q:What is carbon black used for?

- Carbon black is primarily used as a pigment in various industries, such as rubber, plastics, printing inks, and coatings. It provides color, enhances durability, and improves the overall performance of the products it is incorporated into.

- Q:What are fossil fuels and how are they formed?

- Fossil fuels are natural resources that are formed from the remains of ancient plants and animals. They are non-renewable sources of energy that have been used by humans for centuries. The three main types of fossil fuels are coal, oil, and natural gas. The formation of fossil fuels begins with the organic matter that comes from plants and animals. Over millions of years, this organic matter becomes buried deep within the Earth's crust. The process of fossilization occurs as layers of sediment build up over time, putting pressure and heat on the organic matter. In the case of coal, the organic matter is mostly plant material that has been compacted and heated over time. As the pressure and temperature increase, the plant material undergoes a chemical transformation, gradually turning into coal. The formation of oil and natural gas is slightly different. It starts with the remains of tiny marine microorganisms, such as plankton, that have settled at the bottom of ancient oceans. Over time, these organic materials become buried under layers of sediment and are subjected to immense heat and pressure. Under these conditions, the organic matter gets transformed into a mixture of hydrocarbons, which is the main component of oil and natural gas. The oil and gas then migrate through porous rocks until they are trapped by impermeable layers, forming oil or gas reservoirs. Overall, the formation of fossil fuels is a slow geological process that takes millions of years. It requires specific conditions of heat, pressure, and burial to convert the organic matter into coal, oil, or natural gas. Due to their limited availability and the environmental impact of their combustion, there is an increasing focus on transitioning to renewable energy sources as a more sustainable alternative.

- Q:How is carbon used in the manufacturing of electronics?

- Carbon is used in several ways in the manufacturing of electronics. One of the primary uses of carbon in electronics is as a key component in the production of carbon nanotubes. These nanotubes have exceptional electrical conductivity and mechanical strength, making them ideal for use in various electronic devices. For instance, carbon nanotubes can be used to create high-performance transistors, which are essential components in computer chips. Additionally, carbon is utilized in the manufacturing of batteries for electronic devices. Carbon-based materials, such as graphite, are commonly used as the anode material in lithium-ion batteries. This is because graphite can store and release lithium ions efficiently, allowing for the rechargeable nature of these batteries. Furthermore, carbon is employed in the production of conductive coatings and inks used for printed circuit boards (PCBs). Carbon-based materials, such as carbon black or carbon nanotubes, are added to these coatings and inks to enhance their electrical conductivity. This enables the proper flow of electrical signals throughout the circuitry of electronic devices. In summary, carbon plays a crucial role in the manufacturing of electronics. It is used in the production of carbon nanotubes for high-performance transistors, as anode material in lithium-ion batteries, and in conductive coatings and inks for printed circuit boards. These applications highlight the versatility and importance of carbon in the electronics industry.

- Q:How does carbon affect the formation of permafrost thawing?

- Carbon can have a significant impact on the formation of permafrost thawing. Permafrost is a layer of frozen soil, rock, and organic matter that remains at or below freezing for at least two consecutive years. It acts as a natural carbon sink, storing large amounts of organic carbon from dead plants and animals that have accumulated over thousands of years. When permafrost thaws, this stored carbon starts to decompose, releasing greenhouse gases such as carbon dioxide and methane into the atmosphere. The carbon released from permafrost thawing contributes to the overall increase in greenhouse gas concentrations, exacerbating climate change. Additionally, as permafrost thaws, it becomes more vulnerable to erosion and subsidence, leading to changes in the landscape and the release of even more carbon. This process can create a positive feedback loop, where the released carbon further accelerates permafrost thawing, resulting in more carbon emissions. Furthermore, permafrost thawing can also impact the stability of infrastructure built on frozen ground, such as roads, buildings, and pipelines, leading to significant economic and environmental consequences. In summary, carbon plays a crucial role in the formation and thawing of permafrost. The release of carbon from thawing permafrost contributes to climate change, accelerates the thawing process, and has various environmental and economic impacts. Addressing carbon emissions and finding ways to mitigate permafrost thawing is essential to combatting climate change and preserving the stability of these frozen ecosystems.

- Q:What is carbon nanowire?

- Carbon nanowire is a nanoscale structure composed of carbon atoms arranged in a wire-like shape, which exhibits exceptional electrical, thermal, and mechanical properties.

- Q:What are the implications of melting permafrost on carbon emissions?

- The implications of melting permafrost on carbon emissions are significant and concerning. Permafrost refers to the permanently frozen ground found in cold regions, consisting of soil, rocks, and organic matter. It acts as a large carbon sink, storing vast amounts of organic material, such as dead plants and animals, which have been frozen for thousands of years. However, with rising global temperatures, permafrost is thawing at an alarming rate, leading to potential release of this stored carbon into the atmosphere. When permafrost thaws, the organic matter within it decomposes, releasing greenhouse gases, particularly carbon dioxide (CO2) and methane (CH4), into the atmosphere. Methane is an especially potent greenhouse gas, with a global warming potential over 25 times greater than that of CO2 over a 100-year period. The release of these gases further contributes to climate change, exacerbating the already accelerating warming trend. The implications of melting permafrost on carbon emissions are twofold. Firstly, the release of large amounts of CO2 and methane from thawing permafrost can significantly amplify the greenhouse effect, leading to more rapid and intense climate change. This can result in a feedback loop, where increased warming causes more permafrost thawing, releasing more carbon, and further accelerating global warming. Secondly, the release of carbon from permafrost also affects global carbon budgets and climate change mitigation efforts. The stored carbon in permafrost is estimated to be twice as much as is currently present in the Earth's atmosphere. As this carbon is released, it adds to the overall carbon emissions, making it more challenging to achieve emission reduction targets outlined in international agreements, such as the Paris Agreement. It also means that efforts to limit global warming to well below 2 degrees Celsius above pre-industrial levels become even more crucial. Furthermore, the release of carbon from permafrost also impacts local ecosystems and communities. Thawing permafrost can lead to the destabilization of infrastructure, including buildings, roads, and pipelines, as well as the disruption of traditional livelihoods, such as hunting and reindeer herding. It can also cause land subsidence and increased coastal erosion, threatening coastal communities and biodiversity. In conclusion, the implications of melting permafrost on carbon emissions are far-reaching. It not only exacerbates climate change by releasing potent greenhouse gases into the atmosphere but also hampers global efforts to mitigate carbon emissions. Sustainable actions to reduce greenhouse gas emissions and protect permafrost ecosystems are crucial to minimize these implications and safeguard our planet's future.

- Q:Appearance, hardness, electrical conductivity, use of carbon 60

- C60 is a molecule composed of 60 carbon atoms in the molecule, it is like football, so also known as footballene (C60. This material is composed of C60 molecules, rather than by the atoms.) C60 is simply made of carbon atoms with stable molecules, it has 60 vertices and 32 sides. The 12 is Pentagon and 20 hexagon. Its molecular weight is about 720.

- Q:What is the impact of carbon emissions on agriculture?

- Carbon emissions have a significant impact on agriculture as they contribute to climate change, leading to adverse effects on crop yields, soil fertility, and water availability. Increased levels of carbon dioxide in the atmosphere can enhance photosynthesis to some extent, but this positive effect is often offset by rising temperatures, altered precipitation patterns, and increased frequency of extreme weather events. These changes disrupt traditional growing seasons, promote the spread of pests and diseases, and reduce food production. Additionally, carbon emissions also contribute to air pollution, which can further harm plants, livestock, and human health. Therefore, reducing carbon emissions and adopting sustainable agricultural practices are crucial to mitigate these negative impacts and ensure food security for future generations.

- Q:How is carbon used in the production of carbon nanowires?

- Carbon's unique properties make it a key component in the production of carbon nanowires. These nanowires are typically created through a process called chemical vapor deposition (CVD), in which a carbon-containing precursor gas is decomposed in a high-temperature environment. To carry out this process, a reaction chamber is utilized, where a carbon source like methane or ethylene is introduced. The precursor gas is then heated to a temperature above 600 degrees Celsius, causing it to decompose. This results in the release of carbon atoms that begin to deposit on a substrate material, such as a silicon wafer or metal catalyst. The carbon atoms in the precursor gas tend to form strong covalent bonds with each other, leading to the formation of a graphite-like structure. However, by carefully controlling the growth conditions, including temperature and pressure, the deposited carbon atoms can be arranged in a highly ordered manner to form nanowires. The use of carbon as the fundamental building block for nanowires offers several advantages, including exceptional thermal and electrical conductivity, as well as high mechanical strength. These properties enable carbon nanowires to exhibit unique characteristics, making them suitable for a wide range of applications, such as electronics, energy storage, and sensors. Overall, carbon plays a crucial role in the production of carbon nanowires as the raw material that undergoes decomposition and subsequent rearrangement to achieve the desired nanoscale structures.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FC90-95 Recarburizer -Low Sulphur and low P

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords