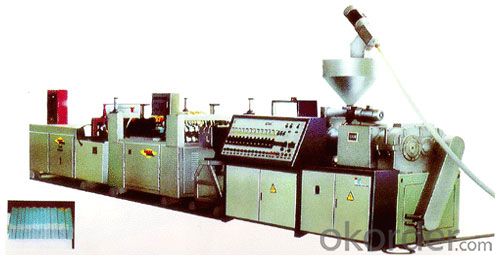

Extruding Wavy Plastic Plates Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruding Wavy Plastic Plates Production Line

With SJSZ-60x22 Taper Twin-Screw Extruder combined with corresponding wavy plate molder,drawing auxiliary machine and cutter, SJLB-60x22-1000 set for extruding wavy plastic plates can continuously produce the coloured,weather-resistant and flame-retardant wavy UPVC plates used in the construction. If replacing the relative pare, it can also produce flat and grid plastics plates. The set has the characterisitics of good plasticizing,stable performance,compact structure,high automatic degree and convenient operation, is the ideal productive equipment for construction manufactures.

Model of Main Machine | SJSZ-65 x 132 |

Die Form | Coat Hanger plane Die L=1000mm |

Molding Unit | |

Great Wave | R=15 H=16.5 Pask Distance=63mm |

Little Wave | R=9 H=8 Pask Distance=36mm |

Length of Molding Roll | 1000mm |

Motor Power | 1.5kw(Frequency-Changing Requlation) |

Dimension of Cooling Mold | 1000mm x 540mm |

Cooling Mode | Cooling Water |

Drawing Speed | 0.5 – 5m/min |

Drawing Power | 2.2KW(Frequency-Changing Requlation) |

Cutting Mode | Shearing(Oil Pressure) |

Cutting Follower Distance | 500mm |

Working Pressure of Gas Line | 0.4 – 0.6Mpa |

Conical twin screw plastic extruder:

Features Specifications:

1. Model SJZ series conical twin screw extruder is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produce all sorts of PVC plastic pipe, profile, plate material, sheet material, bar material and granulation.

2. The conical twin screws have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. The conical twin screw extruder system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plasticity performance and material quality.

4. The conical twin screw is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear larger extruding pressure.

6. The electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1degree.

All SJZ Series Conical Twin-Screw Extruder Technical Parameter:

Model | SJZ-51 | SJZ-55 | SJZ-65 | SJZ-80 | SJZ-92 |

| Screw Dia.(mm) | 51/105 | 55/110 | 65/132 | 80/156 | 92/188 |

Max. Rotating speed(rpm) | 40 | 38 | 38 | 37 | 36 |

| Main Motor(kw) | 18.5 | 22 | 37 | 55 | 90 |

Capacity(kg/h) | 80~100 | 100~150 | 150~250 | 250~380 | 380~700 |

| Center height(mm) | 1050 | 1050 | 1050 | 1050 | 1100 |

| Net Weight(kg) | 3000 | 3500 | 4000 | 5500 | 8000 |

| L*W*H | 3.6*1.1*2.1 | 3.6*1.1*1.2 | 4.2*1.5*2.4 | 4.7*1.5*2.4 | 6*1.6*2.5 |

Plastic Pipe Extruder/Plastic Extruders:

Different types of extruders With different sorts of molds and auxiliary machines,

it can produce all sorts of PVC plastic pipe material, profiled material, plate material, sliced material, bar material and granulation.

It can also extrude PP.PE pipe at high speed by changing special barrel.

Computer control or conventional control is optional.

According to customer's requirements, most reasonable screw can be made so as to achieve best plasticity state and material quality.

The screw is made by high precision special digital screw miller; extruding property can be highly harmonized.

It has firstly introduced advanced technique of producing screws with variable pitch and depth, so that the material can be more softly sheared and cut.

The distribution box is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged.

It can bear larger extruding pressure.

- Q:I am going to work as a worker in a plastics factory. I wonder if the work inside it is very polluting. Is there any harm to the health?

- Phthalates can pass through the plastic containers of food and water into the human body, such as canned food, coating, recycled milk and mineral water bottles, etc. two. Research shows that the fat content in canned food with higher food is more vulnerable to pollution, such as pork, anchovies, sardines etc.. Fetuses and infants and adolescents are most sensitive to it, and health is the most vulnerable.In order to reduce the adjacent benzene two formic acid ester for the human body, usually pay attention to it is best not to use the foam containers to instant noodles, do not use plastic containers containing PVC in the microwave heating entrance food. The correct way to do this is to heat the food in a heat-resistant glassware or ceramic.

- Q:profit is not big, about how much investment, please expert advice, mainly to supply the market and small supermarkets

- I just do this, the raw material is used PE, equipment, there are mainly blowing machine, punching machine, if you want to print, then also the printing press, there are other stirring what ah!

- Q:shopping bags, what equipment prices? Raw material type and material price? Please expert advice

- It is better to make plastic parts than plastic ones

- Q:Plastic PS with ABS and other mixed processing?

- OPP: oriented polypropylene (film)PP: PolypropyleneIt's a semi crystalline thermoplastic. With high impact resistance, strong mechanical properties, resistance to a variety of organic solvents and acid base corrosion. It is widely used in industry and is one of the common polymer materials. Australian coins are also made from polypropylene

- Q:How can we deal with the pollution of waste plastic particles?

- According to the Huacheng machinery senior experts, the current problems like water plastic particles in the machining process can be improved through the method of building see sedimentation tank, water can be reused. The odor problem Huacheng machinery experts tell us, within the industry there is a technique to dispose of smoke and smell. This is a great progress of waste plastics recycling industry.To solve the difficult problem of plastic pollution in the process of granulation, you can be more assured of practitioners engaged in processing. Through investigations now waste plastic particles of the market space is still very great development prospect is good.

- Q:What kind of machinery does it take to open a workshop type plastic product factory? How much is the investment?

- You have to say what kind of products you want to make, such as extrusion or injection molding, which are different and different in price.

- Q:In Shengze where you can find what rags processed into a plastic factory

- You mean it woven rags! Use a plastic granulator.

- Q:Plastic POM POM generally used for the production of what plastic products?

- Fire regulating ring, support member, gear, rack, rubber wheel, remote control switch bracket, cam pressure bar, cosmetic container, toy car runner, mobile phone chute

- Q:What kind of equipment does the plastic product factory need?

- Like universal printer, you can achieve this effect. In some plastic shell, plastic, plastic stationery and other top brands.

- Q:Types of plastic machinery

- Characteristics of injection molding machine control system:1. 、 adopt advanced computer control of famous factory;2. self diagnostic fault function;3. direct input pressure, speed, time, travel and temperature data;4.LCD color liquid crystal display (pictured below);5. centralized lubrication;6. pressure coupling circuit saves power;7.24 V DC oil pressure directional valve coil never damaged;8. die cooling water regulator;9.M.C.B. insurance electrothermal control;10. advanced computer control system, large screen display, operation interface, easy to use cylinder;11. high-precision electronic ruler stroke control, accuracy up to + 0.1mm;12. improve reproducibility by using pressure and oil feedback;13. mechanical, electrical, hydraulic 3 heavy safety devices, in any case can ensure the safety of the operator (PD60-PD148 matching oil pressure);14. improve the reproducibility and operability by installing superior position sensors;15. using closed-loop control to achieve ultra precision forming.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Extruding Wavy Plastic Plates Production Line

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords