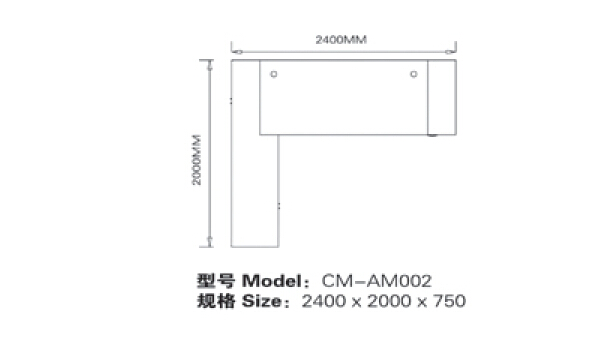

ExecutiveTable Office Desk MDF Hight Quality Wood Melamine/Glass D45

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

| Type: | Office Furniture | Specific Use: | Office Table | Wood Style: | Metal,MDF,Melamine |

| Certification | ISO9001 Quality & Enviroment | Size | 2800*2800*1050 | Advantages | Attractive Design ,Competitive Price |

| Assembling Guide | Available | customization: | Yes | Specific Uses | Office Desk ,Executive Desk |

| MOQ | 5 sets | Payment Term | T/T,L/C | Delivery Time | 15-20 days |

We specialized in office desk and office seating .Our factory has been engaged in office furniture for more than 10 years. Our factory is well-known in the high quality and competitive price of our products. Therefore, we completed in specifications and win warm praise from customers. In addition, the design of our products is deft, modern and beautiful. There are many types and colors for your selection. Our goods are easy and simple to handle and durable in use.

Welcome any questions!

- Q:What is the production process of bamboo plywood?

- The four roller coating machine soluble phenolic resin on bamboo roller coating glue water, the quantity is 300, 350g/ square meters (double). Adhesive can be added 1%--3% flour, soy flour and other fillers. The filling agent causes the bamboo sheet to form a gum film on the surface after gluing, which is difficult to produce flowing glue when hot pressing, and the brittleness of the adhesive layer can be improved after curing.

- Q:How much is the wall of punched plywood one square metre?

- Light steel keel frame, plywood surface, single-sided 85 yuan / square, double-sided 115 yuan / square meter. Plywood is not suitable for partitions. One is the fear of water, water absorption will become uneven.

- Q:Which is better, solid wood or plywood?

- Process difference: multi-layer solid wood flooring and each slice will adopt scientific elimination of internal stress, arranged in a crisscross pattern, at present, the layers from the 7 layer to the 9 layer, 11 layer range; and general splint or plywood layers according to needs, relatively less in the balance of internal stress on the demand is far better than multi-layer solid wood this is our floor strictly, the daily common splint or plywood bend reason.

- Q:The ABS rubber plate is thicker. What tool can you use to cut it?

- Also known as the knife knife or wallpaper knife, is a kind of art and craft knife, mainly used for cutting soft things, for the plastic knife handle and a blade is composed of two parts, for pulling type structure.

- Q:How are the plywood made?

- Symmetry principle: single plate symmetrically on both sides of the central plane, regardless of species veneer thickness, layer, manufacturing method, water fiber direction and single board rate should correspond with each other, namely the principle of symmetry on both sides of the plywood central plane corresponding layers of equivalent stress in different directions. Therefore, when the change of veneer moisture content, its stable structure, no deformation, cracking and other defects; on the contrary, if the central symmetry plane on both sides of the corresponding layer has some differences, will make the central symmetry both sides of the plane board is not equal to the stress, deformation and cracking of plywood.

- Q:What is laminated board? What is plywood?

- The plywood is logs into veneer or by wood sliced veneer, with adhesive glued into three or more layers of sheet material, usually with odd veneer, and the fiber direction of adjacent plates perpendicular to each other and gluing.

- Q:About up to the use of modified rubber sheet!

- The price is almost the same, there is nothing particularly worthy of recommendation. Play mode, Qu Feng Tang, Shangzhi toys, roaming model, Qu Feng Tang, the KING model, they generally have a sheet, you see what love style!

- Q:What is the difference between solid wood composite board and plywood?

- ) material difference: multi-layer solid wood flooring to take into account the different "anisotropy", so that the production process can fully balance the "internal stress", in addition, we need to consider for the thermal conductivity of ground bearing capacity for geothermal; and general plywood or plywood over this.

- Q:How to distinguish between good and bad construction wood board?

- Looked up look up mark imported plywood original packaging is printed with English letters. Made 1. mark. Marked 2. specifications, the general standard 3mm x 4 x 8 or 1220 x 2440 x 3mm, some standard 4 x 8 x 3PLY (4 x 8 three layer), and some direct plate thickness 2.7mm. 3. marked adhesive for plywood, the glue can be divided into a class and two kinds of rubber, a / is waterproof glue, codenamed "P", the two is waterproof glue, codenamed "D". Marked 4. grade standards, grade AA, grade AB, grade BB and grade CC, China imported more than a "mixed level 22" and "33" in each half. As for BB, the market of CC grade plywood, a It is sheer fiction. The import package is marked with the "D/BB, D/CC" mark. Some 5. is printed on the port of shipment and the port of destination, each box has the sequence number, especially with the patterned trademark in the eye-catching position.

- Q:The difference between laminated lumber and plywood

- LVL (Laminated Veneer, Lumber, LVL) is made of thick veneer along the longitudinal direction of laminated blank, hot pressing and cutting into materials; plywood is made of wood into veneer or by wood sliced veneer, with adhesive glued into three layers or multilayer plate material, usually with odd veneer, and the fiber direction perpendicular to the adjacent layers of veneer glued together.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

ExecutiveTable Office Desk MDF Hight Quality Wood Melamine/Glass D45

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 60 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords