Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

TPU raw materials:

1. various kinds

2. competitive price

3. 30 years of experience

4. stable quality

TPU raw materials:

1. Applications and cable specifications of TPU raw materials:

Used for water-resistant power cables, data cables, and spring wire.

2. Description of TPU raw materials:

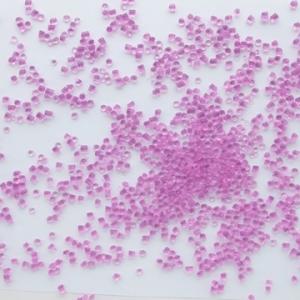

Environmental friendly halogen-free TPU cable compound, based on TPU elastomer resin, is made into granules by mixing, plastification and granulation with adding special modifier and other special additives. It has well performance of tenacity, scratch-resistant, flexibility, Stretch Resistance, and temperature resistance, owning exquisite appearance and smooth surface. It does not contain halogens and heavy metal, in line with the environmental directives of RoHS, REACH. Different hardness can be customized according to customers’ requirements.

3. Processing of TPU raw materials:

The compound can be processed with conventional extruders. It is recommended that the screw L/D should be greater than 25 and compression ratio should be 1:2.5.

The following temperature(°C) profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Neck | Head | Die |

temperature °C | 150 | 170 | 155 | 175 | 178 | 178 | 175 |

Note:Compound should be dried at 80-90°C before use, which has stayed in storage more than one month.

4. Storage and transport of TPU raw materials:

Packaging:25kg/bag,Aluminum foil and PE film bag inside, and PP compound bag outside.

Storage and transport: Avoiding in direct sunlight and weathering. The storage should be clean, cool, dry, and ventilated.

5. Properties of TPU raw materials:

Item | Unit | E7385 | E8385 | E8685 | E8685F | ||||

Standard | Typical | Standard | Typical | Standard | Typical | Standard | Typical | ||

Density | g/cm3 | -- | 1.19 | -- | 1.21 | -- | 1.28 | -- | 1.27 |

Hardness | Shore A | -- | 85 | -- | 85 | -- | 85 | -- | 85 |

Tensile Strength | ≥MPa | 18 | 22 | 22 | 28 | 20 | 25 | 20 | 24 |

Elongation at Break | ≥ % | 550 | 700 | 500 | 650 | 500 | 650 | 450 | 600 |

Thermal aging | °C*h | 136°C*168h | 136°C*168h | 121°C*168h | 121°C*168h | ||||

TS retention | ≥ % | 75 | 103 | 75 | 105 | 75 | 104 | 75 | 102 |

EB retention | ≥ % | 75 | 81 | 75 | 84 | 65 | 89 | 65 | 86 |

Hot deformation | 150°C*4h | 150°C*4h | 150°C*4h | 150°C*4h | |||||

Variation on thermal deformation | ≤ % | 50 | 12 | 50 | 7 | 50 | 6 | 50 | 6 |

pH value of gases released | ≥ | 4.3 | 56. | 4.3 | 5.3 | ||||

Conductivity of Gases released | ≤μm/mm | 10 | 1.2 | 10 | 1.3 | ||||

Impact Brittleness Temperature | ≤ °C | -60 | Pass | -55 | Pass | -50 | Pass | -50 | Pass |

Volume Resistivity, at 20°C | ≥Ω*m | 1.0×1012 | 2.1×1013 | 1.0×1013 | 5.2×1014 | 1.0×1013 | 3.4×1014 | 1.0×1013 | 1.8×1014 |

Flame retardant grade | UL94 2mm | V0 | pass | V0 | pass | ||||

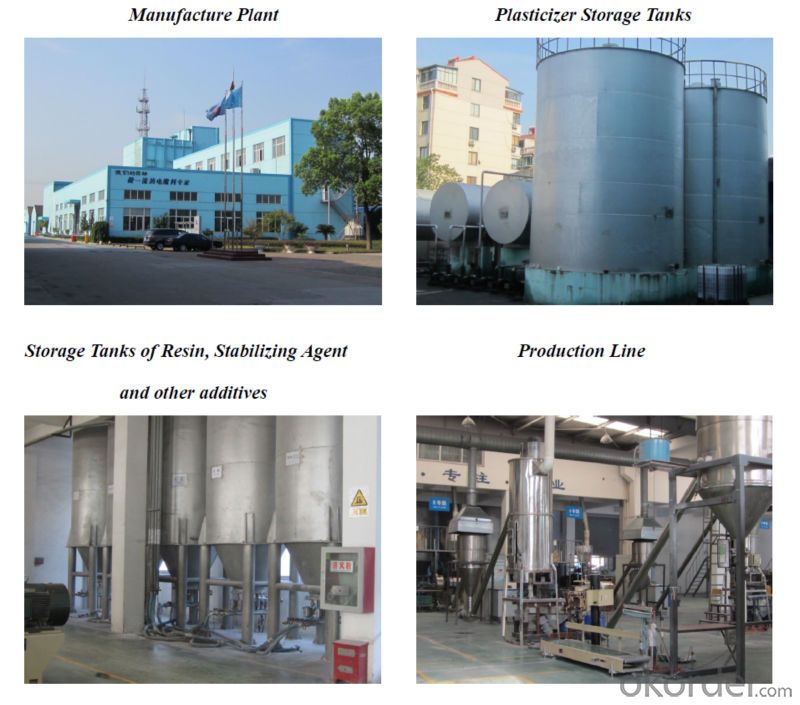

6. Company

- Q:What is the difference between PPA plastic raw material and PP?

- Two kinds of materials are two grades, figuratively speaking, PPA is Benz, PP is alto.

- Q:What material is best for plastic gears?

- Gears can be made of PA, POM, etc., but PA and POM will have noise at high speeds.

- Q:How many kinds of raw materials are produced by wrapping plastic film?

- There are many kinds of plastic film, each of which has the corresponding raw materials, we look at the production of raw materials for various films!

- Q:What is the difference between plastic particles and raw materials?

- PVC is a PVC, bright color, corrosion resistant and durable. Due to an increase in the manufacturing process of plasticizer, anti ageing agent assisted a number of toxic materials, so their products generally do not store food and drug.

- Q:PP plastic stool surface with those raw materials, what is the ratio?

- PP is crystalline polymer. PP is the most common plastic, and the density is only 0.91g/cm3 (smaller than water).

- Q:Raw materials for making plastic bags

- Polyethylene (Polyethylene, PE), referred to as PE. It is a high molecular organic compound which is made up of ethylene. Polyethylene is recognized as the best food for contact with food in the world. Non-toxic, tasteless, odorless, in line with food packaging hygiene standards. Polyethylene film, light and transparent, with moisture-proof, anti - oxygen, acid, alkali, air tightness, heat sealing and other outstanding performance. Known as "plastic flower" laudatory title. It is the most important and most important material in plastic packaging and printing.

- Q:Plastic pipe gas temperature 150 degrees, plastic pipe surface problems?

- The most widely used plastic pipe is plastic pipe. There are many kinds of plastic pipes, which are divided into two categories: thermoplastic pipes and thermosetting plastic pipes. It belongs to thermoplastic, including PVC pipe, polyethylene pipe, polypropylene pipe, POM pipe, super high molecular weight polyethylene pipe, etc. it belongs to thermosetting phenolic plastic pipe. The main advantages of plastic pipes are good corrosion resistance, light quality, convenient molding and easy processing. The disadvantages are low strength and poor heat resistance.

- Q:What are the raw materials for plastic products? Resin or oil?

- Plastic is a kind of macromolecule organic material with resin as its main component. It can form a definite shape at a certain temperature and pressure and maintain a definite shape at normal temperature.Usually refers to the resin conversion or melting range when heated into force with mobility, at room temperature is organic polymer solid or semi-solid or liquid plastic, it is the most basic and most important components. Broadly speaking, in the plastics industry, any polymer used as a basic material for plastics can be called resins.

- Q:PVC what chemicals do you need for plastic surface treatment?

- Different processing methods are often required for different materials.

- Q:How do plastic materials come from?

- Plastic materials: is made of macromolecule resin (polymer) as the main ingredients penetrate various auxiliary materials or additives, in particular temperature, has the plasticity and fluidity under pressure, can be molded into shape and maintain the same shape of material under certain conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Environmental friendly halogen-free TPU compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 350 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords