Electric Planer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Pcs pc

- Supply Capability:

- 10000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electric Planer 900W

* CNP82-3A

* Rated Voltage: 230-240V~50Hz

* Rated Input Power: 900W

* No-load Speed: 16000rpm

* Max. Planing Width: 82mm

* Max. Planing Depth: 3mm

* Rabbeting Depth: 15.5mm

* Packing: 52*35.5*40cm/6pcs, 17/18kgs, 2280pcs/20’cy

* W/CE, GS, EMC, ROHS

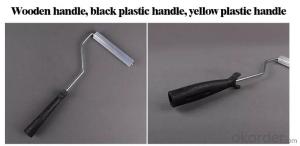

Product Description of Electric Planer 900W

Take the work out of leveling and smoothing doors, window frames, and other woodworking projects with this planer. Features a 5.2-amp high-torque motor for a long life and deep cutting capacity; 3-1/4" planing surface; 5/64" deep cutting capacity which removes more material in a single pass; lock-on button for added convenience during extended use; 5/16" rabbeting depth capacity for edging; chamfering groove for decorative edging; and front depth adjustment handle design for added comfort and control.

1.Simple blade setting system for fast blade installation

2.Lock-on button for continous operation

3.Center V-groove, located on base sole for bevel cutting

4.Features an dust collection system for efficient removal of debris keeping the workspace clean and safe

- Q:What devices must be available for all hand held electric tools?

- Hand held electric tools, insulation measures are in good condition, must be equipped with qualified leakage protection device, forbid to change the power cord and plug, use special flow switch box.

- Q:What's the difference between a flashlight and an electric screwdriver?

- As the mechanical component, the electric screw driver can work without the electric batch power supply, and the batch power supply provides the energy and the related control function for the electric screwdriver. Drive the motor. Since the parameters of the motor are different, the speed will be different when the power of the batch power supply is the same.

- Q:How are hand powered tools classified into class I, class II, class III?

- Simple methods are: hand-held electric tools for metal shell for class I. The plastic case is of the type ii. Class III uses safe voltage.

- Q:What is the working principle of power tools?

- AC motor, AC motor of induction motor, its strong induction current (eddy current) magnetic field generated in the rotation of the magnetic force on the rotor copper bar, continuous cutting, according to Lenz's law, the induced current has the effect of relative motion occurs against the rotor magnetic field and the rotor is, with the magnetic field and rotation. But the rotor rotation speed of the high speed magnetic field does not transform, otherwise it will not be able to cut the copper lines.

- Q:Which is good between pneumatic tools and power tools?

- The use of pneumatic tools:1., the air is easy to obtain, and the work pressure is low, the used air can be discharged locally, without the need to recover the pipeline2. gas viscosity is small, flow resistance loss is small, easy to central gas supply and long-distance transportation3. pneumatic actuator, high movement speed4. the pneumatic system has a strong adaptability to the environment. It can work reliably in a wide temperature range, humid and dusty environment, with a slight leakage, no pollution to the environment, no fire and explosion hazards, and safe use5., simple structure, convenient maintenance and low cost6. long life of pneumatic components7. pneumatic actuators of the hydraulic output than small, fast, strong adaptability, can exercise in the flammable, explosive, heavy, damp, the impact of the harsh environment, no environmental pollution, long service life, simple structure, easy maintenance, low price.

- Q:How are the I, II, and III classes of power tools classified?

- The popular point is that:The 1 type of tool is metal housing with ground wire.The 2 type of tool is the insulated housing.The 3 type is low voltageOfficial point of explanation can be searched for power tool category ~!

- Q:What other tools are there for the furniture except the pistol hole?

- It is mainly used in construction, decoration, furniture industry, opening for objects or objects in the past, also known as hammer in some industries.Well, there are more drilling tools on the market now.

- Q:Why hand grinding sand turbine, electric drill, impact drill and other power tools plug is two, plug is not three plug

- In recent years, leakage protection performance and the reliability greatly, has become a standard power supply, reliability of human protection over ground protection to a certain extent, but the impact of grounding protection and leakage protection to human body protection, so many hand-held electric tools to cancel the earthing protection, relying instead on leakage protector. And use the two eye plug.Look at the instructions for the hand-held power tools with two plugs. All require that the power supply be equipped with an electric leakage protector.

- Q:Power tools are power tools?

- Now, that's pretty much the case. Now most power tools are powered by electricity. However, some of them are pneumatic, especially the environment where no electrical work is required. This should be equipped with an air pump externally.Small, of course.

- Q:What are the commonly used rotor types for power tools?

- Electric drill: the main specifications are 4, 6, 8, 10, 16, 19, 23, 25, 32, 38, 13, 49mm and so on. Figures refer to the maximum diameter of the drill drilled on the steel whose tensile strength is 390N/mm. For non-ferrous metals, plastics and other materials, the maximum drilling diameter is comparable to the original specifications of 30 to 50%.Electric grinding machine: a tool for grinding with a grinding wheel or millstone. A vertical electric wheel and electric angle grinder.Electric wrench and electric screwdriver: used for loading and unloading threaded fittings. The driving mechanism of the electric wrench is composed of a planetary gear and a ball screw groove impact mechanism. Specifications are M8, M12, M16, M20, M24, M30 and so on. The electric screwdriver adopts the embedded clutch, transmission mechanism or gear drive mechanism. The specifications include M1, M2, M3, M4, M6 and so on.The hammer and drill: used for concrete, brick and building components on drilling, slotting, dehairing. With expansion bolts, installation can improve the speed and quality of pipeline, machine equipment; impact hammer principle is to rely on the internal movement of the piston impact force, impact principle of impact drill is running in gear impact force, so the impact hammer is greater.

1. Manufacturer Overview |

|

|---|---|

| Location | Jiangsu,China |

| Year Established | 1994 |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | ENGLISH,CHINESE |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electric Planer

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1000Pcs pc

- Supply Capability:

- 10000Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords