Corundum Insulating Fire Bricks and Low AP Mullite for Hot Surface Lining Steel Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Corundum Insulating Fire Bricks and Low AP Mullite for Hot Surface Lining Steel Furnace

Product Description for Corundum Insulating Fire Bricks

General Information CMAX mullite brick is a kind of high alumina refractory brick which takes the mullite (3Al2O3 & 2SiO2) as the basic crystalline phase. Alumina content is generally between 65% to 75%. Feature High refractoriness High compressive strength Application Glass furnace Heating furnace Chemical kiln Metallurgic furnace.

Structure& Advantage for Corundum Insulating Fire Bricks

Characteristics of our Mullite Insulating Fire Brick IFB (JM-IFB):

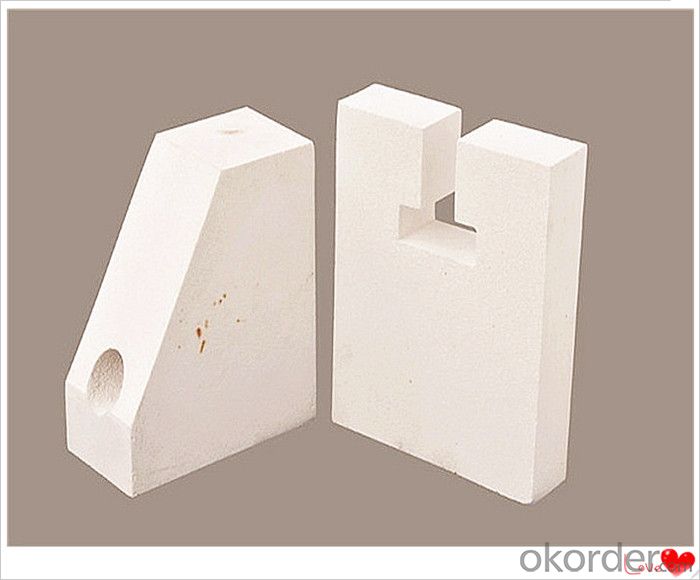

1) After shaping and sintering, cutting and grinding processing are done, drilling is necessary according to brick drawings.

2) Little impurities of iron and alkali metal

3) High temperature resistance

4) uniform structure and high cold crushing strength

5) Good thermal shock resistance, stable volume, good insulation performance in high temperature

6) Low thermal conductivity

Application: Our brick can be used as a hot face lining directly exposed to the fire, as a backup insulation layer in iron and steel mills, non ferrous foundries, petrochemical, ceramic, glass, cement and oil fired electric power generating plants.

We Are Suppiler for Corundum Insulating Fire Bricks

Below are some of our customers

Allied Mineral Products,inc

Refractories Incorporated

Srs Sorg Refractory Systems GmbH,

Sunward Refractories Co.,Ltd

Lilama69-1 Joint Stock Company etc.

Raw Material for Corundum Insulating Fire Bricks

Image for Raw Material

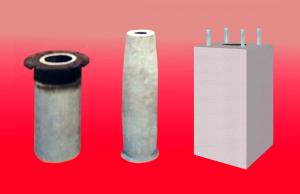

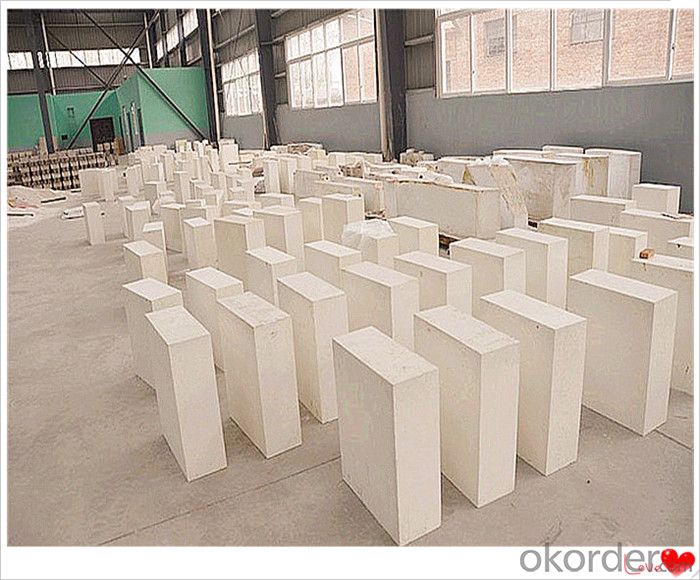

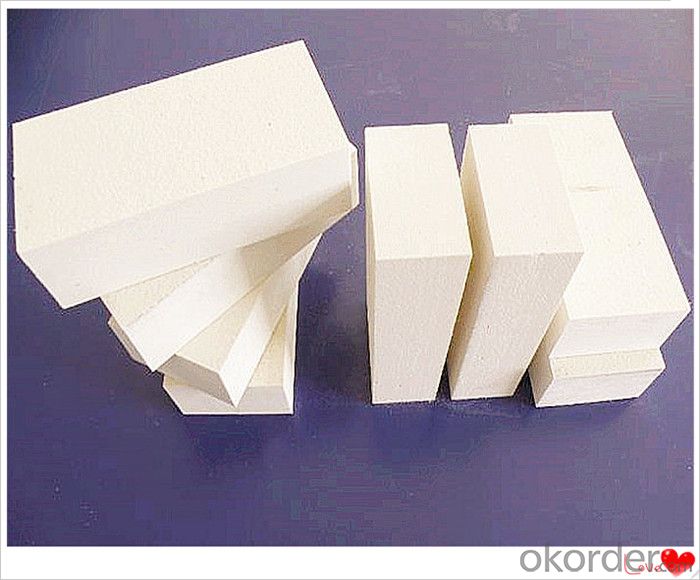

Major Images for Corundum Insulating Fire Bricks

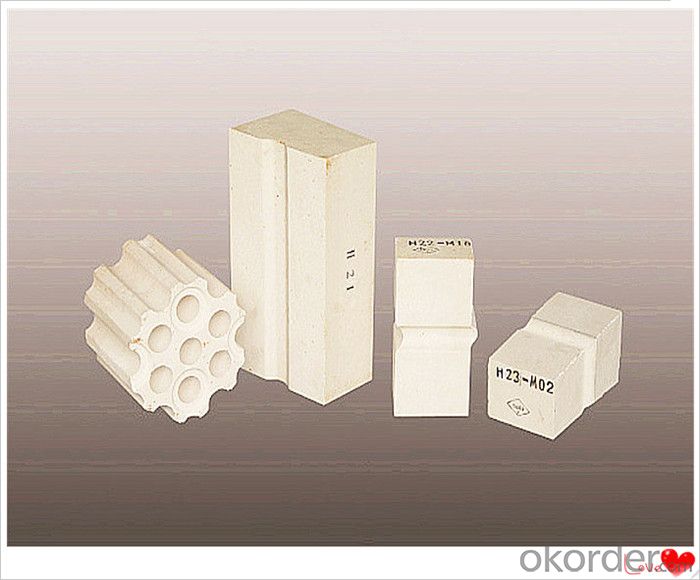

Corundum and Mullite Bricks & Other Shape Bricks

Other Shape Corundum and Mullite Bricks & Other Shape Bricks

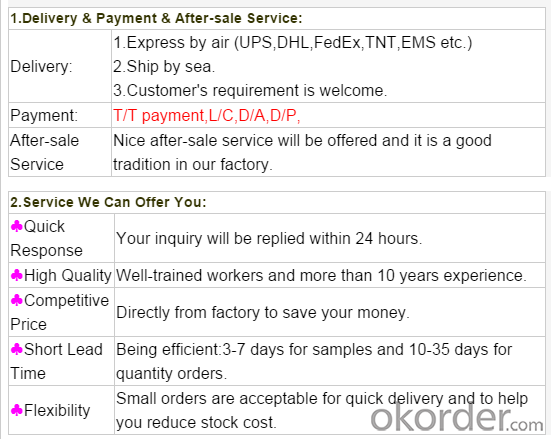

Packaging & Delivery for Corundum Insulating Fire Bricks

1.The Corundum and Mullite Insulating Fire Brick will be packed as the standard of exporting or packed on wooden pallet with three layers water-proof shrink film and tightened with plastic/steel bandages,when in the transportation process,we should pay attention to moisture-proof and light handling.

2.The packing of Refractory Brick will accept customer's requirement if any.

3.Delivery within 7-15 working days after your payment.

4.Fast delievery accepted by customers.

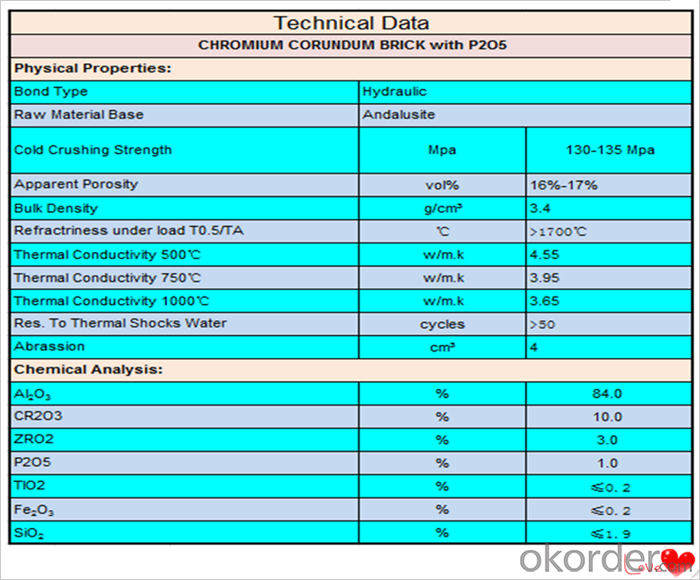

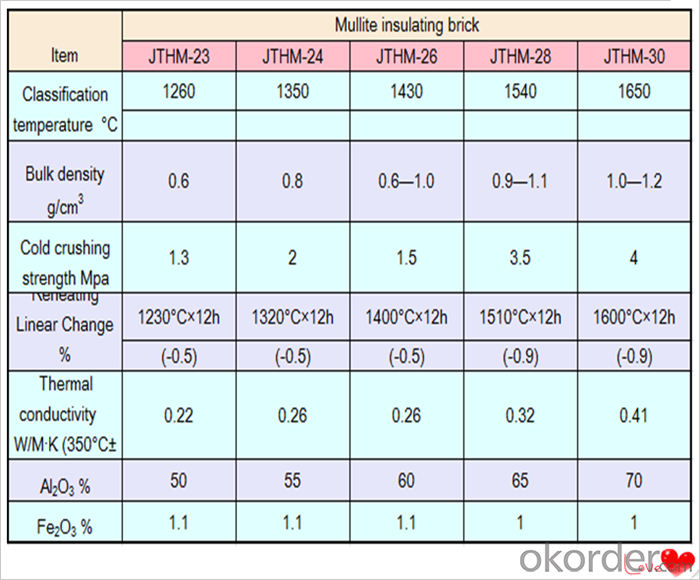

Specification

for Corundum Insulating Fire Bricks and Mullite Brick

Why Us

1. Strong professional:

We are state-owned company, ranking 267th/Fortune Global 500. We have clients from over 160 countries and wholly-owned overseas subsidiaries and branches in 10 countries.

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory’ s production materials, process control, quality supervision and package delivery,and ensure the products are 100% qualified.

2. Annual supply:

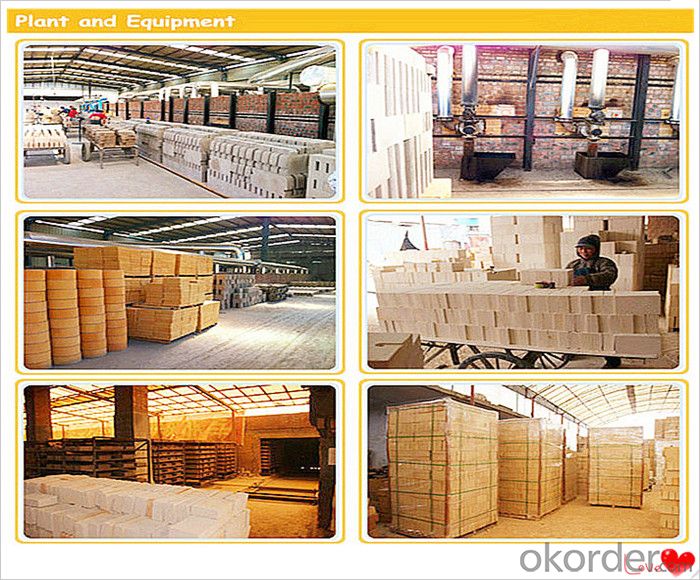

Our company has passed ISO9001 quality management system certification and SGS certification. And the annual supply of shaped and unshaped refractory product is 28,800-35,000 tons..

3. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece,Spain, Congo, Angola, South Africa, and Maldives,Jordan and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

5. Testing equipment;

Our company’s testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

FAQ for Corundum and Mullite Bricks

3.Common question:

Q1:Are you a manufacture or trader?

A:Factory+trade(mainly factories, at the same time,we operates other related products).

Q2:Can we visit your factory?

A:Sure,welcome at any time, seeing is believing.

Q3:What's the MOQ of trial order?

A:No limit,We can offer the best suggestions and solutions according to your condition.

Q4:Which payment terms can you accept?

A:T/T,L/C are available for us.

Q5:After an order is confirmed, when to deliver?

A:15-25days after deposit.

Q6:Is your company accept customization?

A:We have own factory and excellent technical team,and we accept OEM service.

Q7:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary certification.

Q8:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q9:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q10:What is the service life of your bricks?

A:The service life of different bricks is unlike.It also depends on your using condition and method.

- Q:Expansion ratio of lightweight corundum refractory bricks

- Now with the production of lightweight foam corundum brick, basically still meters with molding casting, moulding after together with die in the drying room drying in 60~70 C 4 days of release, then the appropriate drying, finally after 1300 and 1550 C firing, the total burning time: 50~60h. Light corundum brick after firing is usually not the size and shape of accurate, so that products after the kiln to mechanical or manual cutting, can be made into a density of 0.8 - 1.3g/cm3, 4MPa compressive strength and porosity, the thermal conductivity of 70%~80% 0.17W/ (M - K), light-weight corundum brick use temperature of 1500~1700 DEG C.

- Q:High temperature refractory material?

- Now the definition of refractory materials, has not only depends on whether the refractoriness at 1580 DEG. Refers to the current refractories used in metallurgy, petrochemical, cement, ceramics and other production equipment with inorganic non-metallic materials.

- Q:Can the fire clay be reused?

- Refractory soil cannot be reused.Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q:How much is a thermal brick?

- If you really want to buy thermal insulation brick, do not simply look at the price, but also to consider the quality of the product. (a piece of brick in the market basically in 6 yuan, if there is a floating price if it is because of the size of the insulation brick or distance, but floating slightly.)

- Q:What is the main component of corundum?

- Corundum is mainly used in advanced grinding materials, watches and precision mechanical bearing materials. A ruby based artificial crystal used as a laser emitting material. Ruby and sapphire are corundum minerals. Except for the starlight effect, only translucent transparent and vivid corundum can be used as gems. The red is called ruby, while the other tones of corundum are commercially referred to as sapphires.

- Q:Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q:What material is used in an iron smelting furnace?

- In fact, refractory refractory ah is special ceramic frequently used AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.

- Q:What kind of rock is corundum produced?

- If Ti4+ and Fe2+ containing a small amount of blue, a sapphire; containing six symmetrically distributed acicular rutile or other inclusions in some crystals, can produce six star awn, known as star ruby or sapphire stars, are precious stones. Corundum is vitreous luster with no cleavage, but cracks occur because of the presence of poly twin crystals that are often formed by the base or face of a face. Specific gravity 3.98. Of relatively low silicate igneous and metamorphic rocks and common in alluvial deposits. The U.S. state of North Carolina and Georgia, Russia's Ural mountains, South Africa as the main origin of the transvaal.

- Q:What is the hardness of corundum refractory bricks?

- Such as zirconium corundum refractory brick, chrome corundum refractory titanium corundum refractory brick.

- Q:What problems should we pay attention to in the use of fused zirconia corundum brick (fused zirconia corundum brick) in glass furnace?

- Cast brick and clay brick masonry contact, eutectic phenomenon will occur at 1300 degrees Celsius, the selection of refractory materials, should avoid eutectic phenomenon serious two kinds of refractory materials such as brick masonry contact, in the following cast brick, the most vulnerable to erosion fused zirconium corundum brick.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Corundum Insulating Fire Bricks and Low AP Mullite for Hot Surface Lining Steel Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords