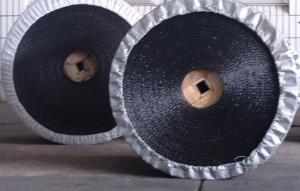

Copper Wire Wearing Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Application: It is mainly used for packing and isolation of cable conductor and cove,has

cushioning and shielding effect.

Property | Unit | TF-TZD40 |

Thickness | mm | 0.40±0.05 |

Weight | g/m2 | 200±10 |

Tensile Strength | N/cm | ≥150 |

Elongation | % | ≥5 |

Short Term Stability | ℃ | 250 |

Long Term Stability | ℃ | 110 |

- Q:Semi automatic packing and full automata are used for packing and distinguishing

- Third, the difference between lift and lift is not a little; that is to say, if the semi automatic strapping belt receives 40 kilograms of tension, the new material can withstand 180-200 kilograms

- Q:Permanent packaging machine packaging belt is not in place, how to repair?

- Incorrect wearing.Open the right door, in accordance with the instructions on page fifth marked "threading process" or the right door in the side wear band diagram, the right to wear.

- Q:What's the difference between PP strapping and PET packaging?

- Pet packing belt is suitable for packing large and heavy materials, such as glass, steel, stone, brick and so on. It is more suitable for long distance transportation. The PP straps are suitable for packing cartons or other lighter objects. The steel belt is suitable for auto parts, oil drums and so on.The above mainly from the material, performance, cost, safety and use of simple analysis of the PET packaging belt, PP packaging belt and steel belt three packaging tape, respectively. In order to facilitate the vast numbers of users with good choice, different packaging belt, packaging different products. Double glow PET belt has been widely used in the steel industry, aluminum, glass, wood, stone, brick and so on.

- Q:Do you need cross straps to check your suitcase?

- In order to prevent the luggage in the consignment way because the bump or extrusion damage, resulting in the goods lost or damaged, the use of cross strap fixed on the luggage box, is good.

- Q:What should I pay attention to, such as whether it should be printed on the inner surface or the outer surface? Also, can the pure transparent packing belt be printed? What are the special requirements for ink? Will increase the cost, etc., we sincerely hope that your heroes.

- First of all, the extruder temperature control is generally between 250 and 280 degrees centigrade. The next is cooling, strip out the head temperature is very high, to immediately enter the water cooling, because of isotactic polypropylene in acute cold conditions easily generated has crystal structure, molecular structure of paracrystals was loose. In this way, the strap is easy to stretch and obtain high quality products. Then, the tensile and tensile purposes are to increase the longitudinal strength of the strap and reduce the elongation. Tension must be carried out in boiling water, usually by one stretch. Finally, the embossing, stretching after the packaging belt, after two patterns of pressure roller, it will be pressed on the pattern, its role is to increase friction in use, do not slip, from the appearance of looking handsome.

- Q:What is the reason that the packing belt of the packer is not glued?

- Packaged with adhesive effect is not good and there will be a lot of reasons, may be the head temperature is not enough, it may be of poor quality tape

- Q:Packing belt

- Glossary: name of PP polypropylene, polypropylene as a raw material for the production of lighter quality for the environmental protection packing belt, automatic packing machine, semi-automatic packing machine, manual packing machine, carton or pallet packaging for bundling several kilograms to hundreds of kilograms lighter object.

- Q:Identification of PP packaging belt

- Some packaging machines with new materials outside, the middle folder filling material (poor), as long as the cut open to see the section, you can see inside the black heart is poor quality.Packing machine with color problems, packaging machines with different grades, hard to say. The transparent baler belt is the best strapping belt at present. The quality of the packing machine depends entirely on the purity of polypropylene. The higher the purity of polypropylene, the better the tension of the baler.

- Q:Identification of the quality of the packing belt

- PP packing belt identification: packing belt straightness standard, uniform thickness, color is not fade, pull to the foot, to see if the new material will be packaged with cut with scissors, look at the joints, packed with intermediate black is relatively poor, the raw material is PP, one can understand.

- Q:How should the packing tape be printed?

- The characters on the packing belt are not printed on the back, but made directly. It is a belt with Chinese characters.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Copper Wire Wearing Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords