Copper Mylar Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Copper Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Copper Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Copper Mylar foil Shielding Foil:

Copper Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

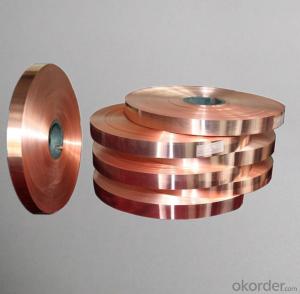

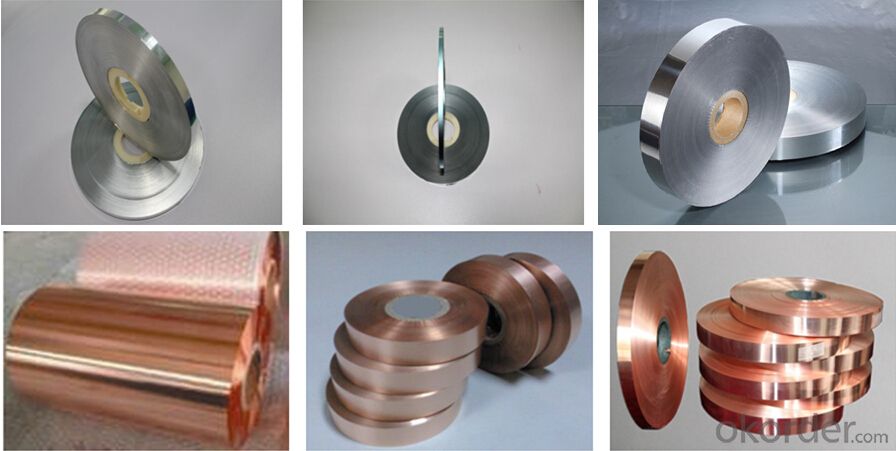

3. Copper Mylar foil Shielding Foil Images

4. Copper Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q:What are the areas in which aluminum foil is applied?

- International and domestic production and application of inorganic polymer flocculant have scale, theoretical research has also been further developed. The main raw materials are bauxite, aluminium hydroxide, waste molecular sieve catalyst and so on. The main preparation methods are wet method, electrolysis method and so on. Some scholars believe that the aluminum foil has the advantages of high recovery and reuse of economic value. He experimentally studied the optimum conditions for the preparation of polyaluminium chloride by using waste aluminum foil and the applicable range of the purified water

- Q:When installing gas water heater in our house, the installation master will connect the aluminum foil smoke pipe directly to the smoke exhaust port of the machine, but the Internet says it can not be installed like this. What's wrong with this?

- Case 2:1, smoke pipe distance from the ceiling in accordance with the requirements should be greater than 50mm, but the machine smoke pipe almost affixed to the ceiling, a serious violation of regulations;2, open the hole in the wall is not sealed, connections are not used aluminum foil sealing tape; the flue gas flow backward user ceiling blackened, cause accidents.

- Q:Outdoor camping in East China, with only one foil damp barrier in the tent, plus sleeping bags? Do you need inflatable mats?

- On this basis, if you can add a piece of cotton canvas to do moistureproof matBecause this is absorbent in itself

- Q:With aluminum foil bag vacuum packed food, placed in the pot steaming, a total of three layers, the above two layers are all right, the bottom layer is broken, what is the matter ah ~ ~!

- The problem of glue, as well as ordinary vacuum bags, is a normal problem, after all, it's not a cooking bag. Instead of cooking CPP, a vacuum bag that can be used for cooking.It is not a special cooking bag, so it is easy to break when steaming.

- Q:The aluminum foil I bought reads, "microwave ovens, be sure to refer to the microwave oven instructions."".My microwave oven has barbecue. With foil wrapped in meat into the microwave oven, how should operate? Is that all right? With a microwave or a light wave?

- Microwave oven using skills:1, the use of aluminum foil. Other parts of the corner pointed wings, chicken or fish head, tail or cake too easy to cook, cover with aluminum foil wrap can achieve the purpose of cooking evenly.2. Use of vessel cover or plastic film seal. When cooking, stewing food and fried vegetables, in order to preserve the original flavor of the food, prevent excessive evaporation of water, and accelerate the cooking speed, the vessel cover or plastic wrap should be used.

- Q:Considerations for hand held aluminium foil sealing machine?

- This machine is not suitable for metal container and metal cap and anodized aluminum paint cover on the metal surface, no heating press button, otherwise it will damage the machine, such as metal cap and anodized aluminum paint cover, aluminum foil can be screwed on the bottle cap.2, this machine is in use, the operator should always pay attention to the temperature sensing head, such as hot hot hand (about 80 DEG C) should stop working for natural cooling or use a fan induction head alignment sensor head forced rapid cooling, the temperature sensing head down to room temperature (25 degrees Celsius) again start to work, so the sensor head of high temperature damage.

- Q:When the wire is made, it needs a layer of foil inside, and the outside is insulated. Why is that?

- Wire, usually used as a signal wire, is used as a shield to reduce interference from external signals to the transmitted signal;

- Q:Why aluminum foil can escape metal detector?

- It is not even below the sensitivity of the metal detector and therefore cannot be explored

- Q:Can foil work at 430 degrees high temperature?

- Therefore, it can be inferred that if oxidized, the final result may not be aluminum foil, but also alumina. A touch may be powdery...

- Q:Can I use the foil instead of the baking paper?

- Depends on what to bake, baking paper is usually oil paper, there is anti sticking role

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Copper Mylar Shielding Foil for Cable Foil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords