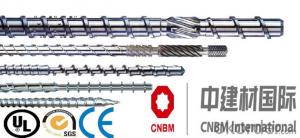

CMAX Parallel Twin Screw and Barrel For Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

conical twin screw barrels for PVC pipe&profile&WPC extruding machine

Product Description

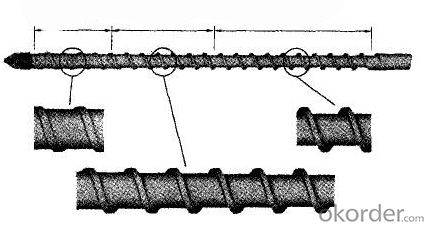

Material

High quality alloy-steel

1) 38CrMoAlA(JIS SACM645)

2) 42CrMo(JIS SCM440)

3) 9Cr18Mov

4) CW6Mo5Cr4V2

Heat-treatment

Nitriding treatment

Electroplated hard-chrome finish

Spray bimetallic coating

our service

In today’s competitive market, making a PVC or other extruder product at maximum productivity levels and the lowest possible cost is paramount in growing your business, increasing profits and meeting your overall business objectives.

For over one decades CNBM has been a leading supplier in machine components for the Plastic, Food and Rubber industry. Flite Technology has earned the reputation as an innovator and industry leader in the manufacturing of precision single and twin feed screws and barrels. Whether it's new, rebuilding, designing or repair, you can be confident our service, quality and performance will be unsurpassed.

We also offer very aggressive competitive pricing. Pick up and delivery service is available as well as reverse engineering for existing worn out parts.

We are focus on service for solution, not only supply screw barrel.

We can do any kind of screw barrel for extruder molding machine, injection molding machine and blow molding machine, see the application as below

FAQ

screw barrel

1.Q: How about CNBM?

R:CNBMChina National Building Materials Group Corporation)(Fortune Global 500 companies)is a state-owned CNBM is state owned largest building materials and equipment manufacturer and supplier, we have more than more than 500 factories.

2. Q:What's CNBM capacity

R:Passed ISO 9001:2008, Our workshop 12000SQM, thousands good experienced employee, All CNC computer control screw processing, 1000sets screw barrel capacity per month.

3. Q:What's the delivery time

R:for regular size, we have finished stock and semi-finished stock, 2weeks max enough

for customized, normally 3~4weeks.

4.Q:How about CNBM screw barrel quality and price

R:Germany Technical invested, top quality in China with competitive price and engineers available to service machinery overseas after-sale service

5. Q:How to make sure the screw suitable for my extruder?

R:Let's know what size you want and we can check it with our drawing. If your extruder is made in China,it's easy to get the original drawing.

6. Q:what's the life time and guarantee buy from CNBM screw barrel?

R:3~5years life time for nitriding ones and bimtallic ones will be longer One year min. Guarantee

7.Q:How to contact with you

R:just reply to me below if have any question.

Company Information

CNBM International Corporation

(CNBM International) is the most important trading platform of CNBM Group Corporation, a state-owned company under the direct supervision of State-owned Assets Supervision and Administration Commission of the State Council.With the advantages in Cement, Composite Materials, New Building Materials and Engineering, We are enlarging sub-brand. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization. Meanwhile, we have established strategic partnerships with hundreds of domestic manufacturers and sound business relations with clients from over 120 countries. In line with the business, CNBM International launched E-business platform Okorder.com. It conformed the best resource and logistics to meet the customers’ request with 24 hours full-time service.

Our Vision: Initiate new global trading structure; create new value for benefit related partners.

We will do utmost to promote rational use of resources under the new structure, meanwhile, create new value of “green, environment friendly and sustainable’ for a more prosperous future.

CNBM International Co. Carpet Dept.

At CNBM International Co. Carpet Dept., we design and weave beautiful carpets of superb durability - with axminster, tufted and wilton carpets to suit all hospitality environments. · There is no size limitation on rug size. Rugs can be created with a variety of materials from pure wool to woolen silk, from natural fiber to chemical fiber.

- Q:Plastic machineryWhat about plastic machinery?

- I just said a few who had done the granulator (mixers and injection molding, cooling system, cutting machine, injection molding machine) and vertical (generally, a small product) and horizontal (general and products), granulator is mainly raw materials (powder) with the same color as rice processing the product after injection molding to produce the final product

- Q:Jiangyin Milacron Plastics Machinery Co. Ltd.

- Group has 32 affiliated enterprises, with a total assets of 3 billion 500 million yuan, in the national molding industry in a leading position. The main production of various kinds of plastic moulds, car mechanical energy and all kinds of steel structural parts, automotive tooling and fixture, Yu Zhou bus, automobile trade and all kinds of engineering plastics and other products, and is involved in real estate, hotel and circulation.

- Q:There are equipment in the home, in principle, plastic or metal auto parts can be processed. Where can I pick up the list?

- Do more advertising yourself! Print out! Those small units that do not have machine tools often send them small advertisements!

- Q:(such as supplies, automotive accessories such as plastic plastic) LOGO technology company, who understand the general characteristics about this aspect, the amount of direct is to help guide a breakthrough point, mainly manifests in the company development business characteristics.

- Many companies are using LOGO company name of the phonetic alphabet with simple graphics (such as round, square, diamond), which can be used as a way of thinking; in addition, some enterprises LOGO is pictographic, such as the Great Wall automobile LOGO like the Great Wall, the merchants group LOGO as a "business". I hope to help you, I feel reasonable, give points!

- Q:What is the 34 curtain pinch 6? I just know it's a mechanical finishing material

- 34CrNiMo6, Cr- Ni- Mo chromium nickel molybdenum, for high temperature and low temperature stainless steel fasteners

- Q:What accessories does PPS engineering plastics use on the car?

- PPS/PTFE, PPS/PA, PPS/PPO and other alloys have been commercialized. PPS/PTFE alloy has improved the brittleness, lubricity and corrosion resistance of PPS. PPS/PA alloy is a high toughness alloy.Excellent heat resistance: its melting point is more than 280 degrees, the thermal deformation temperature is more than 260 degrees centigrade, and the long-term use temperature is 220-240 degrees centigrade. The degradation rate of the inert gas is 1000 at 700 DEG C in the air, and the weight of the inert gas remains 40%. The thermal stability of the short term heat resistance and long-term continuous use is superior to all the existing engineering plastics. The temperature of hot deformation can reach above 350 degrees after specially modified varieties.Its flame retardant: polyphenylene sulfide flame retardant can reach UL94-0, oxygen index (LOI) >57%. Polyphenylene sulfide has its own chemical structure, so it has good combustion resistance, without adding flame retardant.

- Q:Plastic machinery industry in recent years, the output value? Import and export data? Preferably with industry analysis

- Since the machine industry system has been initially formed more than 20 years, the overall strength of China plastic machinery industry is growing, but the industry is far from mature, are in urgent need to solve two problems: one is the unreasonable industrial structure. Another big problem is the backwardness of R & D level. China has become the world's largest producer of plastic machinery, with output accounting for 25% of the world's total output, but only 9% of its output value. Behind the high yield and low price is the lag of independent innovation. Innovation requires investment, but investment is not enough, machinery manufacturing and plastic processing of touch, no specific innovation mode weakens the efficiency of innovation.Independent innovation is an indisputable path, but for innovation model, it should be more detailed, more targeted. For domestic original innovation, one should give more tolerance; two, through risk investment and other ways to establish risk aversion mechanism; three, to attract the attention of the whole industry and to support it.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Parallel Twin Screw and Barrel For Plastic Extruder

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords