Cleaning In Place Machine for Stainless Tanks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

Processing: Washer, cutting-rolling -welding -polishing -assembing -testing -warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: CIP cleaning machine, KB-009

Voltage: 380V, 50HZ

Certification: B&V, CE

Warranty: one year

After-sales Service Provided: Engineers available to service machinery overseas

Packaging & Delivery

| Packaging Details: | export standard package |

|---|---|

| Delivery Detail: | 25 - 45 days after deposit received |

Images:

Specifications

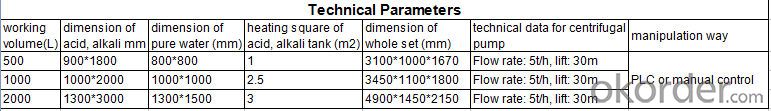

1.acid storage tank 2.alkali storage tank 3.fresh water storage tank

4.centrifugal pump 5.pipes and valves

| CIP Cleaner | |

| Company introducation | We Kuangbo is a production enterprise of pharmaceutical, dairy, food and beer-making equipment, alongside biological engineering, chemical containers, and bespoke products. Our products are widely used in beer production, pharmaceuticals, beverage industries, biotechnology and other fields. |

| Usage | it is used for cleaning pipes and tanks after the production process |

| Material | 1.SUS304, 316L |

| 2.as to the thickness, we can make it according to your requirement. | |

| Configuration | 1.acid storage tank |

| 2.alkali storage tank | |

| 3.fresh water storage tank | |

| 4.centrifugal pump | |

| 5.pipes and valves | |

| Our advantage | 1.we can supply various kinds of volume, minimum 50L, maximun 2,000L. |

| 3.interior surface is 3A finish and exterior is 2B finish | |

| 4.competitive price and also higher quality tank. | |

| Minimum order | one unit |

| Payment term | T/T or L/C |

| Package | export standard package |

| Market | at home and abroard |

- Q:What is the difference between a boiler operating certificate and a class?

- Note 1: Class III boiler operators can work with Class II, Class I boiler operators, Class II boiler operators can work with Class I Boiler Operators.

- Q:14MW hot water boiler is how many tons

- Hot water boiler 0.7MW is equal to 1 ton.

- Q:My heat boiler is sometime leaking when it is running. It uses water heat. My friend said it is because the pressure is too high and suggested me to turn down the tempereture little bit. I turned turn from 210F to 200F. It leaks less ofter, but still leak. One thing I notice is the cool water valve is always turned on (since it was installed 3-4 years ago), but my friend's is always off. Should I turn off my cool water valve? Is it dangerous to do so in case the water is dried out? Any avice? Thanks.

- Where is it leaking when it is running? I don't know if the cold water valve your talking about is the valve for the make up water. If it is then it must remain open during the heating season.

- Q:The water content in the boiler is 180 kg. The connected electric heater is 20 kW. Temperature of the water in starting is 27 Deg C. The final steam pressure required is 85 PSI.

- First you have to heat the water and the boiler. Since you say nothing about the boiler you have to neglect the boiler part. You need to look up in a steam table the enthalpy of saturated liquid and vapor at 85 psi (99.7 psia, probably 100 psia is close enough) and figure out how much it changed. The part I don't know is how you know how much liquid you have and how much vapor you have without knowing the volume of the boiler. The two most plausible assumptions you can make here is that the boiler volume will only be large enough to hold the saturated liquid or that it will be so large as to require all the water to be vapor to be able to get to 85 psi. I would guess that you need to convert it all to steam so use that. So you compute the change in enthalpy from water to steam for the whole 180 kg and divide by the power input to get time to get there. Make sure to keep track of the unit conversions between metric and English units.

- Q:I have a Gloworm boiler and I have got a plumber to look at it he said the heat exchanger needs replacing. Also the diverter valve. If the heater exchanger was not working would I still be able to get the heating to work?

- It sounds like a diverter valve isn't working wisely yet fee to repair/replace can variety with the make as some makes could be repaired by potential of fixing the motor interior the valve that's plenty greater fee-effective than a valve substitute. Pump can be enjoying up,attempt finding the fee change interior the terminal cover, it is two velocity with a change or 3 velocity with a rotary dial and adjut it to work out in case you may hear or sense any difference.New pump on my own(in a container) is around ?ninety + VAT.

- Q:What are the main differences between water pipe boilers and fire pipe boilers?

- Tube tube to achieve heat transfer, fire tube boiler structure is simple, water and steam volume, the adaptability of the load changes, the requirements of water quality than the water pipe boiler, and more for small enterprises in the production process and life heating.

- Q:We had a new boiler installed last year after 5 months and several attempts the installation company has finally got all rads operating (sort of). They have sent me a bill for the last visit 4 hours @ ?45 per hour. Is it reasonable to expect that all rads working, would be included as part of the initial installation?

- All the basic questions: a) One or two-pipe distribution system? b) What did the contract say? Was it for the installation only, or was it for a complete system rework? c) Did the radiator problem exist prior to the new boiler installation? d) And, lastly, hot water or steam? Now, some potential answers: 1. A new boiler should make no difference in how heat is distributed - that is, unless your previous system was gravity and the new one uses a circulator. And if the latter, that will be a two-pipe system. In that case, there will be no need to balance. 2. If you have a two-pipe system, balancing consist mostly of making sure there are no air-locks in the system and that it is properly pressurized, and that the expansion tank is functioning correctly. 3. Which leads me to suspect that you have a single pipe system using inlet valves to determine radiator response. You may also have several zones with their own zone valves. Balancing these systems is very tricky such that demand temperatures (specific load on a specific radiator) can cause changes in how the system responds. And if there are multiple zones, if the demand on one zone changes that will also affect the entire system. Balancing that sort of system is both something of an art-form and typically not included in an installation contract unless requested in advance and specified in writing.

- Q:I have a live steam engine, and I'm taking in ideas of what to burn in the bottom for heat. I use Sterno gel fuel, and it works, but not very good.

- don't have so much water in the boiler. They use Sterno or a candle. I don't know of anything else. Besides this is just to understand the principle . If you want the real thing then you are gonna have to get a real steam train. and track.

- Q:to re-position any replacement to the current 'Diplomat' cast iron model would be very awkward and with an open vented gravity system could I possibly get exemption from John Prescotts 'SEDBUK A/B' ruling by fitting the most efficient alternative (as a condensing boiler might not run at top efficiency anyway without significant modifications all round)Why is there no reference from boiler manufacturers to SEDBUK B grade. I think wet Central Heating is getting too complex and I may consider gas wall heaters instead.Are things improving out there regarding earlier 'teething' troubles with condensing boilers and are conventional boilers still being manufactured?

- You could replace your controls if the boiler is in sound shape (the boiler I work on is 30 years old and the piping is over 90 years old) If you have radiators I would replace the steam traps on each radiator if you haven't done so in the last 5 years. These traps are located on the outlet side at the lowest side of the radiator. Also the chemical balance of the water is critical to the proper function and efficiency of your system.

- Q:Characteristics of biomass boilers

- The fuel is fed into the furnace by the screw feeder, where it is preheated, dried, ignited and burned due to the action of the high temperature flue gas and the primary air. During this process, a large amount of volatiles are precipitated and the combustion is severe.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cleaning In Place Machine for Stainless Tanks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords