China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Type:

T-type Joint Pipe (Push-on)

Standard:

ISO2531

Material:

ductile iron ggg50

Pressure:

PN10, PN16, PN25,PN40

Wall Thickness:

K9, K8, C25, C30, C40

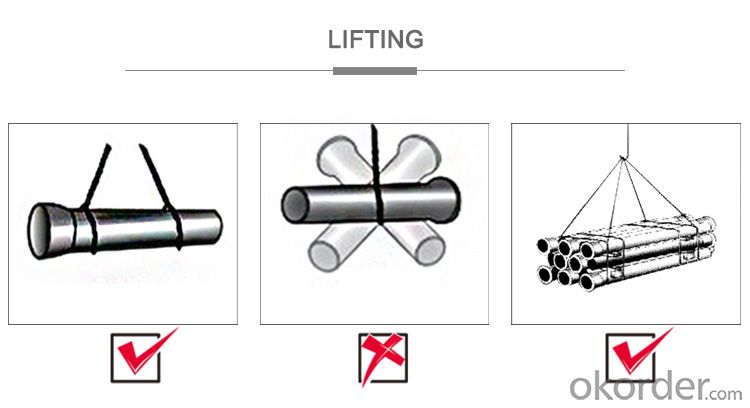

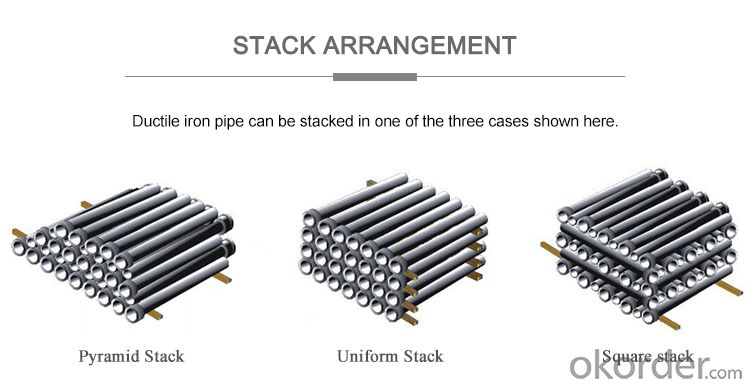

Packaging:

Bundle, in bulk

Yield (≥ MPa):

300MPa

Hardness:

≤230HB

Pull Strength:

≥420MPa

Processing Service:

Casting

Color:

Black, red, blue or as requested

Length:

6m, cut to 5.7m

China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

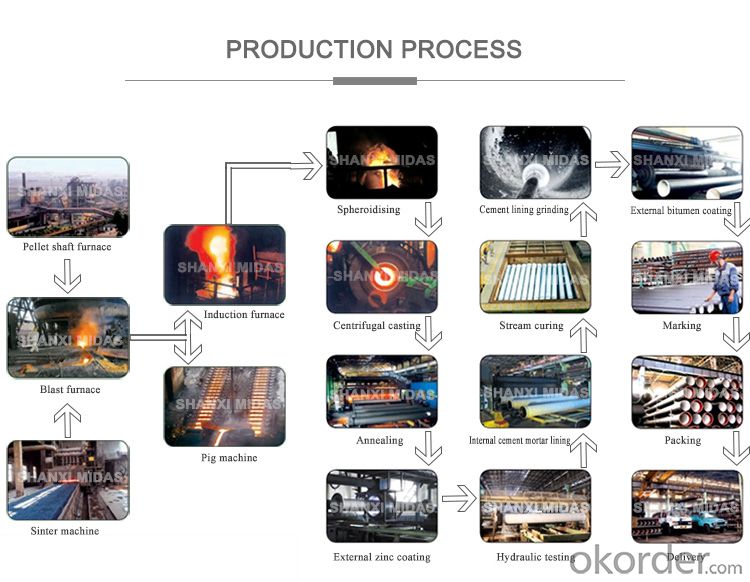

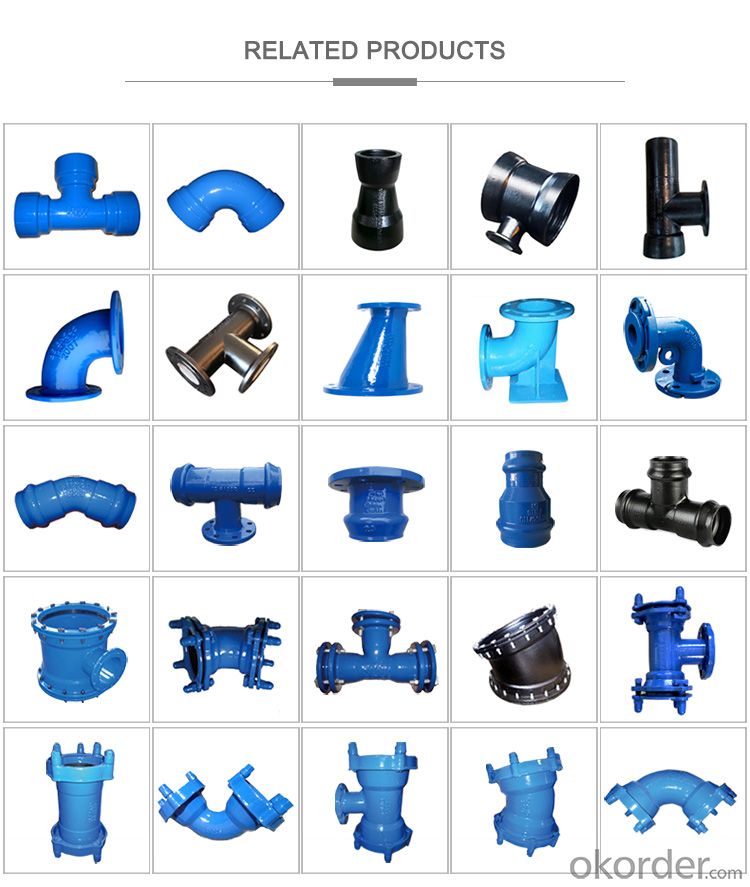

The T-type Joint Pipes (Push-on) produced by our company range from DN80mm to DN2600mm are flexibly jointed with sockets and spigots; they are the first choice in urban water pipe networks due to their convenient installation, strong seismic performances, seal ability and corrosion resistance.

Specifications

| Type | T-type Joint Pipe (Push-on) |

| Standard | ISO2531, EN545, EN598, etc |

| DN | DN80mm~DN2600mm |

| Material | Ductile Cast Iron GGG50 |

| Pressure | PN10, PN16, PN25,PN40 |

| Wall thickness | K9, K8, C25, C30, C40 |

| Length | 6m, cut to 5.7m |

| Application | Water supply project, drainage, irrigation, water pipeline system. |

| Internal Coating | a). Portland cement mortar lining |

| b). Sulphate Resistant cement mortar lining | |

| c). High-Aluminum cement mortar lining | |

| d). Fusion bonded epoxy coating | |

| e). Liquid epoxy painting | |

| f). Black bitumen painting | |

| External Coating | a). zinc+bitumen(70microns) painting |

| b). Fusion bonded epoxy coating | |

| c). Zinc-aluminum alloy +liquid epoxy painting | |

| Package | Bundles, in bulk |

| Note | The coating can also be accordance with customers' requirements. |

Product Images

- Q:How does ductile iron pipe perform in areas with high soil acidity?

- Due to its innate corrosion resistance, ductile iron pipe is highly effective in areas with high soil acidity. It is specifically engineered to endure harsh environments and incorporates a safeguarding lining that shields against damage caused by acidic soil. This lining functions as a barrier, safeguarding the pipe from corrosion induced by the acid in the soil. Moreover, ductile iron pipe exhibits exceptional resistance to external loads, making it well-suited for regions with unstable soil conditions. In conclusion, ductile iron pipe is a dependable option for areas with high soil acidity, as it can withstand corrosive effects and offer enduring performance.

- Q:Will the cast iron pipes rust?

- Qualified ductile iron pipe requires lining standard cement. The outer wall of pipe needs spraying zinc treatment and asphalt paint coating, and other epoxy resin paint can also be selected.

- Q:Are ductile iron pipes suitable for use in mining applications?

- Yes, ductile iron pipes are suitable for use in mining applications. Ductile iron, also known as nodular cast iron, is a type of iron that has been treated with magnesium or cerium to alter its microstructure, making it stronger and more flexible than traditional cast iron. This enhanced strength and ductility make ductile iron pipes highly resistant to impact, corrosion, and abrasion, which are common challenges in mining environments. In mining applications, ductile iron pipes are often used for various purposes such as water supply, slurry transportation, and ventilation systems. Their excellent durability and resistance to wear and tear make them ideal for handling abrasive materials, chemicals, and high-pressure fluids commonly found in mining operations. Furthermore, ductile iron pipes' ability to withstand heavy loads and external pressures makes them suitable for underground mining applications, where they may need to support the weight of overlying rock layers. Their high tensile strength and flexibility help prevent pipe failure and minimize the risk of leaks or breaks, ensuring the safety and efficiency of mining operations. Additionally, ductile iron pipes are relatively easy to install, maintain, and repair. They can be welded or joined using mechanical couplings, allowing for quick and efficient installation in mining sites. Their corrosion resistance also reduces the need for frequent maintenance and replacement, resulting in cost savings for mining companies. Overall, the superior mechanical properties and durability of ductile iron pipes make them a reliable and practical choice for use in mining applications.

- Q:Are ductile iron pipes compatible with other pipe materials?

- Yes, ductile iron pipes are compatible with other pipe materials. They can be connected to pipes made of various materials such as PVC, HDPE, steel, and more, using appropriate fittings and connectors.

- Q:Can ductile iron pipe be used for water supply to remote areas?

- Ductile iron pipe is indeed applicable for providing water supply to far-flung regions. Its exceptional strength and durability render it suitable for transmitting water over long distances. These pipes can endure high pressure and withstand external loads and impacts, making them an ideal choice for rough terrains and remote locations that pose challenges in terms of maintenance and repairs. Moreover, ductile iron pipes are equipped with a protective lining that prevents corrosion and guarantees the safety of the water for consumption. Consequently, ductile iron pipes prove to be an effective and dependable option for water supply to remote areas.

- Q:Usage of ductile iron pipe expander

- Ductile iron expansion is mainly provided with large flexible, easy installation, the product main material for nodular cast iron, nodular cast iron is mainly through spheroidization and inoculation by spherical graphite, effectively improve the mechanical properties of cast iron, especially the plasticity and toughness increased, resulting in higher than the strength of carbon steel. The material mainly has high strength of plasticity and toughness, and its development at home and abroad is very fast, the output has exceeded cast steel and malleable cast iron, become second only to gray cast iron casting alloy material. Spheroidal graphite is obtained by spheroidizing and inoculation of nodular cast iron. It can effectively improve the mechanical properties of cast iron, especially improve the plasticity and toughness, so as to obtain higher strength than carbon steel.

- Q:How are ductile iron pipes tested for quality?

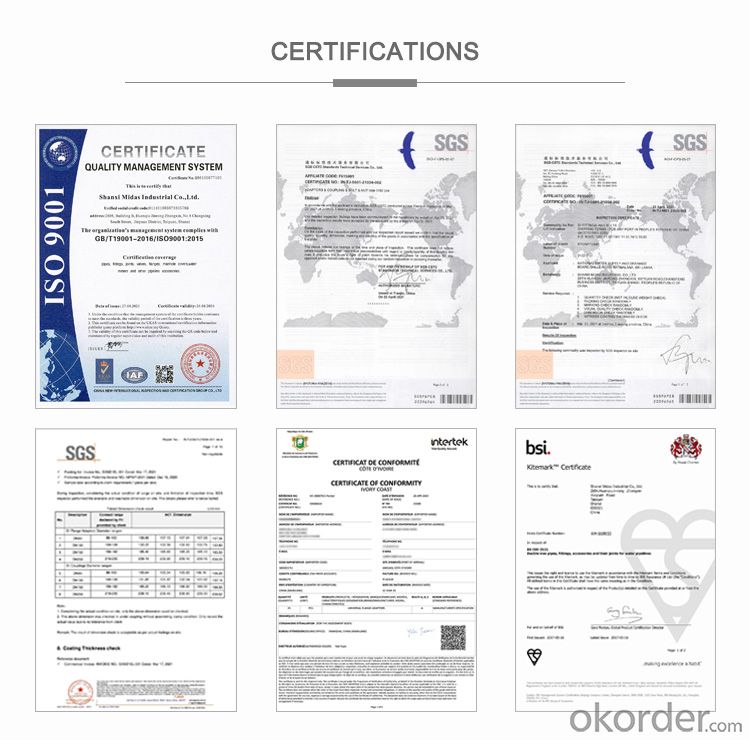

- Ductile iron pipes are tested for quality through various methods, including hydrostatic pressure testing, dimensional inspection, and mechanical properties testing. Hydrostatic pressure testing involves subjecting the pipes to water pressure to ensure they can withstand the intended operating conditions without any leakage or failure. Dimensional inspection assesses the pipes' dimensions, such as diameter, wall thickness, and length, to ensure they meet the specified standards. Mechanical properties testing evaluates the pipes' tensile strength, yield strength, and elongation to ensure they possess the necessary strength and flexibility. Overall, these rigorous testing procedures help ensure the high quality and reliability of ductile iron pipes.

- Q:Ductile iron pipes lined with cement mortar in the water (living water, water in the 6.9-7.3) in the early pH, why pH increased? How to solve this problem?

- The basic characteristic of ductile iron pipe of ordinary cement mortar lining the inner wall of the tube will make passivation, have antiseptic effect, but in the initial stage of using cement mortar lining will be the alkali component separation, so that the pH value of water increased to influence water quality

- Q:What effect does magnesium play in nodular cast iron?

- The role of magnesium as spheroidizing agent used in iron spheroidizing treatment, promote water ink is made of iron, carbon in liquid iron spherical graphite precipitation.

- Q:Are ductile iron pipes suitable for oil and gas pipeline applications?

- Yes, ductile iron pipes are suitable for oil and gas pipeline applications. Ductile iron pipes have numerous properties that make them ideal for use in such applications. Firstly, ductile iron pipes have high tensile strength, which allows them to handle the high pressure and stress associated with oil and gas transmission. This ensures that the pipes can withstand the demanding conditions and maintain structural integrity over time. Secondly, ductile iron pipes are highly resistant to corrosion. Oil and gas pipelines are exposed to various corrosive elements, such as water, chemicals, and salts. Ductile iron pipes have a protective lining, typically made of cement mortar or polyethylene, which prevents corrosion and extends the lifespan of the pipes. Additionally, ductile iron pipes have excellent durability and longevity. They have a long service life, typically ranging from 50 to 100 years, depending on the specific conditions and maintenance practices. This makes them a reliable choice for oil and gas pipeline applications, reducing the need for frequent replacements and minimizing downtime. Furthermore, ductile iron pipes have good flexibility, allowing them to withstand ground movement and absorb shocks and vibrations. This flexibility is particularly important in oil and gas pipeline applications, where the pipes need to adapt to changing terrain and environmental conditions. Lastly, ductile iron pipes are cost-effective compared to other materials commonly used in oil and gas pipelines, such as steel. They offer a favorable balance between performance and price, making them a practical choice for both large-scale and small-scale pipeline projects. Overall, the combination of high tensile strength, corrosion resistance, durability, flexibility, and cost-effectiveness makes ductile iron pipes suitable for oil and gas pipeline applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

China top quality ISO2531 cement lined class K9 DN80 ductile cast iron DCI pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords