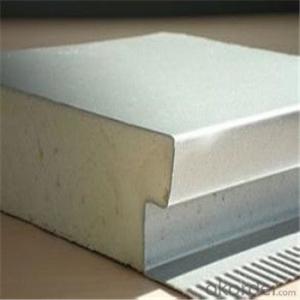

china supplier eps sandwich panel for fast intallation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 1. Free packing (with normal pallet and packing belt) 2. Standard exporting packing (wrapped with plastic thin film,wedge protect and good pallet) 3. Packing size: 1500-3000*610*1000mm 4.Loading: 18 pallets per 20' container |

| Delivery Detail: | 10-15day |

Specifications

1.Light Weight

2. Easy for Installing

3. Sound, Heat Insulation

4. Fire Proof, Water / Moisture Proof

Product Description

2014* light weight concrete eps wallboard

1.EPS nonmetal decorative composite wallboard

2.High Intensity

3.Heat Preservation

4.Fireproof

5.CE&ISO9001

Product Performance

Item | Unit | JG/T 169-2005 | EPS Light Wall Panel | ||||

60mm | 90mm | 120mm | 60mm | 90mm | 120mm | ||

Anti-impact Capacity | Times | ≥5 | ≥5 | ≥5 | ≥5 | ≥5 | ≥5 |

Anti-bending Damage Load | / | ≥1.5 | ≥1.5 | ≥1.5 | ≥1.5 | ≥1.5 | ≥1.5 |

Compressive Strength | MPa | ≥3.5 | ≥3.5 | ≥3.5 | ≥3.7 | ≥3.7 | ≥3.7 |

Softening Coefficient | / | ≥0.8 | ≥0.8 | ≥0.8 | ≥0.84 | ≥0.84 | ≥0.89 |

Surface Density | / | ≤70 | ≤90 | ≤110 | ≤55 | ≤65 | ≤81 |

Moisture Rate | % | ≤12 | ≤12 | ≤12 | ≤1.9 | ≤1.9 | ≤1.9 |

Hanging Force | N | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1000 | ≥1000 |

Dying Shrinkage Value | mm/m | ≤0.6 | ≤0.6 | ≤0.6 | ≤0.3 | ≤0.3 | ≤0.3 |

Heat Transfer Coefficient | / | / | / | ≤2.0 | / | ≤1.45 | ≤1.02 |

Radioactivity Limit | / | ≤1.0 | ≤1.0 | ≤1.0 | ≤0.25 | ≤0.25 | ≤0.25 |

Sound Insulation | dB | ≥30 | ≥35 | ≥40 | ≥35 | ≥38 | ≥42 |

Fire Proof limit | h | ≥1 | ≥1 | ≥1 | ≥2 | ≥2.35 | ≥3 |

Product Feature

1. Lightweight: the wallboard of the weight is about one third than the brick wall of the one,relieving the building loading, Reducing the construction cost.

2. thin-body: the wallboard of the weight is about a half than the brick wall of the one, the occupying area of the wall reduces, the usable area increases.

3. Solid core: no bubble, no empty, slotting notch, potholing, the single-point hanging exceed 50kg.

4. Easy installation: fabricated dry construction, no need plasterer, this way of the efficiency of construction is increase 5 times than the masonry way.

5. Fireproofing: fireproofing, heat-insulating performance better, the 1000℃ of high temperature firing one hour to the wallboard, which of the temperature only 60 ℃.

6. Waterproofing: no need waterproofing disposing, directly use cement to splicing, which become the water pool, the one have no-leakage phenomenon.

7. Sound insulation: According to the test report of the National Center of Quality Supervision & Test for Building Materials, the 120mm thickness wallboard of the sound-insulation reaches 42Db.

8. Energy-saving: the heat transfer coefficient is 0.2, the thermal insulation effect is 3rd time than brick wall of the one, air-condition, heating installation energy-saving reach 60%.

Advantages:

Contraction simple, Efficient, Fast

Increasing usable floor area

Environmental Protection

Anti-seismic Good Integrity

Damp Proof,Waterproof

Sound insulation

Fireproofing

- Q:Sandwich panels and Malacca ecological board what is the difference

- You can use the shear wall, and then hollow insulation can reduce the noise, but the cost of high

- Q:Similar to the color steel tile, floor board, the roof of the push is how much ah

- (Polyurethane waterproof coating, asphalt, etc.); small gap, you can directly hit the silicone sealant; the same time, you can use the silicone sealant, Above all have to ensure that color steel plate fixed firmly, or if loose will damage the water

- Q:Sandwich board is the two sides are metal, the middle of the building materials is the problem of foam added: What is the use of more adhesive

- According to material classification: can be divided into inorganic insulation materials, organic insulation materials and composite insulation materials three types. Inorganic insulation materials are common: YT inorganic reactive wall insulation materials, rock wool board, glass beads insulation mortar, foam cement board, glass wool board and so on. Organic insulation materials are: molded polystyrene board, extruded polystyrene board, phenolic resin board, polyurethane plate and so on. According to the shape classification: can also be divided into plate, powder and so on. According to the fire rating: divided into A-class non-flammable type, B1 grade flame retardant, B2 grade combustible type. Inorganic insulation materials are A-class materials, organic insulation materials up to B1 level.

- Q:Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Color steel room is a color steel composite panels (also known as Caigang sandwich panels) for the wall to light steel structure for the skeleton built. The color galvanized steel coating to maintain a period of 10-15 years, so the theoretical life can be more than 10-15 years, but also with the environment, the use of materials, quality and maintenance methods.

- Q:50mm thickness of color steel foam sandwich board how much money a flat

- The top of a ceiling, pure glass wall of the place to plant flowers to shade

- Q:Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient

- Q:Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q:What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

- Q:Color steel sandwich panels and synthetic resin tile which is more market

- Must be embedded in the concrete beam on the concrete beam, and then fasten the steel pipe connection, the use of steel connection, the connection point can be 2 steps 3 cross, the specific calculation by the book construction

- Q:Are sandwich panels suitable for train stations?

- Yes, sandwich panels are suitable for train stations. Sandwich panels are a type of construction material that consists of two outer layers (usually made of metal) with an insulating core in between. This combination of materials provides excellent thermal insulation, fire resistance, and soundproofing properties, making them ideal for train station applications. The insulation properties of sandwich panels help to regulate the temperature inside the train station, ensuring a comfortable environment for passengers and staff regardless of external weather conditions. This can help reduce energy consumption and lower heating or cooling costs. Sandwich panels are also highly fire-resistant, which is crucial for train stations where the risk of fire is a major concern due to the presence of electrical systems, passengers, and potentially flammable materials. The fire-resistant properties of sandwich panels can help contain and slow down the spread of fire, providing valuable time for evacuation and firefighting efforts. Furthermore, sandwich panels offer excellent soundproofing capabilities. Train stations are typically noisy environments due to the constant movement of trains, announcements, and passenger conversations. The use of sandwich panels can significantly reduce noise transmission, creating a more peaceful and comfortable atmosphere for passengers and staff. Additionally, sandwich panels are lightweight and easy to install, making them a cost-effective and efficient choice for train station construction or renovation projects. They can be customized to meet specific design requirements, allowing for flexibility in architectural design while still maintaining their functional benefits. In conclusion, sandwich panels are indeed suitable for train stations due to their thermal insulation, fire resistance, soundproofing properties, and ease of installation. Their use can enhance the overall comfort, safety, and efficiency of train stations, providing a positive experience for both passengers and staff.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

china supplier eps sandwich panel for fast intallation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords