Calcium Silicate Boards Model 04 with Good Quality for Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Calcium Silicate Board:

A calcium silicate board is one of the new-type building materials recommended by the Ministry of Construction. It is a light, high-strength, fire-resistant and heat-proof material composed of scientific proportions of siliceous and calcareous materials, adulterated with appropriate amount of reinforcing materials, which are processed through pulping, molding, autoclave curing, drying and sandpaper polishing.

Main component:

Wood fiber, cement and so on. The nominal size is 1220*2440/1200*2400, with the maxium length 3.66m.

Physical performance of Calcium Silicate Board:

1.100% non-asbestos

2. Density: 1000-1200 KG/m3

3. Coefficient of thermal expansion: 0.24W/MK(JC/T54)

4. Bending strength: Over 13Mpa(GB/T7019-1997)

5. Linear expansion rate: 0.1%

6. Water absorption rate: Less 0.19%(GB/T7019-1997)

7. Water penetration rate: 0%

8. Water content: 10%

9. Incombustibility, A grade; Waterproof

10. Radioactivity: Standard(GB6566-2000)

Main Characteristics of Calcium Silicate Board:

1. Light weight

2. The wall is solid and firm inside, and resistant to impact pressure

3. Painting, tiling and nailing is possible in the new system

4. Noise reduction can be up to 46 dB

5. Good efficiency

6. Fireproof, damp proof

7. Easy to install 8. Stable dimensions

Specifications of Calcium Silicate Board:

1) Thickness: 4 - 20mm

2) Normal Size: 1220*2440/1200*2400, with the maxium length 3.66m.

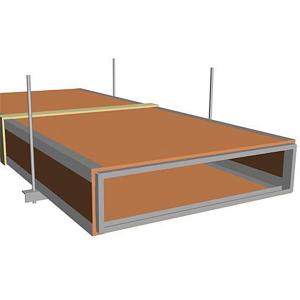

Usage of Calcium Silicate Board:

The magnesium board is widely adoptable to partition and suspending ceiling in decoration of buildings. It is also absolutely suitable to the structure for heat preservation, sound insulation wall places with dampness, mobile partition, special class fire prevevention, sandwiched plate in fireproof- gate and packaging of equipment cases.

Packaging & Delivery of Calcium Silicate Board:

Pieces with palletes or pieces loosely in the container.

- Q:Silicon calcium board wall how to paste tiles

- Silicon calcium board wall tile tiles generally used marble glue plus glass paste, if you must use cement mortar paste, then the silicon calcium board to hang the network, pad block, or because the grass-roots level is too thin Mat cream guard, slightly deformed, the tiles on the empty drums or even fall

- Q:Calcium silicate board ceiling need to do the bottom plate

- Should not be used. Calcium silicate board is based on silica (quartz sand, powder, silicon, algae, etc.), calcium oxide (also useful lime, carbide slag, etc.) and reinforced fiber (calcium silicate board is a new generation of "green" In the excellent moisture-proof, fire performance based on the unique environmental protection function.It is based on silicon powder and calcium powder material as the main substrate to hot wood fiber as a reinforcing material, other auxiliary materials, through the flow molding, High temperature, high pressure maintenance of a new type of fire board building materials.

- Q:Decorative gypsum board is good or good calcium silicate board

- Gypsum board and silicate board has its own advantages and disadvantages: gypsum board: advantages: the relative ratio will be more than the order of the dry dry call sucking by environmental protection, easy construction, easy to crack, affordable; Disadvantages: Plate; silicate board: Advantages: good water resistance; Disadvantages: construction is not convenient cutting, dust easily harmful to the human body. Hope that "home staging" decoration can help you to help, hope to adopt!...

- Q:My family in the north of the countryside, when the original building, the guest 粻 chicken class Tuen Jiu halo Mo hall with a high 1 meter wide and 50 cm tiles close to the wall around the circle, his wife said it looked good, do not want Yes, but the original is attached to the wall with cement, not easy to get down. I would like to ask, can not use gypsum board or plywood stick to the top, how to get, thank you! More

- Can be sealed with gypsum board on top, first in the tile surface drilling into the cork, the interval with 305m 粻 chicken class lesson wine tao Mo Mo * 305mm, and then 3 * 25 flat head tapping screw to the gypsum board fixed Tile surface, if you worry about wet, you can switch to 6% calcium silicate board (recommended use, but also cheaper 12% gypsum board). The simplest can be a single tiles chisel, keep the paste of the cement layer, and then leveling the cement slurry, you can paint the dust

- Q:Decoration

- Calcium silicate board is a kind of siliceous material (main component is SiO2, such as quartz powder, fly ash, diatomaceous earth, etc.), calcium material (the main ingredient is CaO, such as lime, calcium carbide, cement, etc.) Reinforced fiber materials, additives and so on with a certain proportion of the by copy or molding, autoclave curing process made of a new type of inorganic building materials. Because of its high strength, light weight, and has good machinability and incombustibility, it is widely used in the ship's cabin, ceiling and construction of non-load-bearing walls, as well as fire protection requirements of other places. Calcium silicate board for the insulation of calcium silicate board and calcium silicate board. Implementation standards 1, JC / 564.1-2008 Asbestos fiber reinforced calcium silicate board 2, JC / 564.2-2008 Chrysotile asbestos fiber reinforced calcium silicate board industry standard JC / T1049-2007 "ultra-thin natural stone composite panel"

- Q:I have friends want to use calcium silicate board, when the floor with! Do not know if it can? Please talk with friends! Thank you! More

- Absolutely can not, because that acid immediately rot on the acid, too practical

- Q:What is the difference between silicon calcium board and sound-absorbing board?

- Silicon calcium board is a compact board, basically airtight. Relative to the sound-absorbing panels heavier and harder. Is a sealed plate. Mainly from the sound effects. That is to stop the sound on both sides of the space in the spread of space. Sound-absorbing board is porous multi-slit plate, basically ventilated. Most of the things can be directly through the plate to see the other side of the board thing. Mainly from the sound-absorbing effect, that is, to weaken a certain frequency in the board side of the amount of reflection. Very few sound-absorbing panels directly to do the partition, so the sound-absorbing panels are generally not used to deal with the sound problems on both sides of the board, only dealing with unilateral sound field.

- Q:Home decoration, do not know what material is better. The Please help experts to see, hope to get a detailed answer. The Thank you more

- The difference is still there, the main is the Edite plate production process of lime powder and adhesive materials, the intensity will be different

- Q:What is the popularity of the living room recently?

- Gypsum ceiling is best

- Q:How effective! Long time will not fall, I know that hanging grid cloth powder cement mortar, I think this kind of spread to move Ji Jiu Bang Bao magic also out of the fast, there is no more convenient construction methods, such as hanging mesh and then spray cement Mortar plus 107 mortar! Now want to reduce the cost do not want the powder cement mortar, my place when the outdoor, 20 meters long, 5 meters high a new wall, grass is more steel

- I cement pressure plate wire mesh paste tiles

1. Manufacturer Overview |

|

|---|---|

| Location | Foshan, China |

| Year Established | 1996 |

| Annual Output Value | Below US$1 Million |

| Main Markets | Mid East; Eastern Europe; Australia; Africa; Southeast Asia;China |

| Company Certifications | ISO 9001:2008; CE EN12467:2012; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Foshan; Guangzhou; Shenzhen |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 5 people |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | 100,000.00SQM |

| No. of Production Lines | 4 (plan add 2pcs product lines in 2014) |

| Contract Manufacturing | OEM Service Offered; Own Brand; |

| Product Price Range | 6mm Higt Density: USD2.72/SQM, Average price6mm Mid Density: USD1.85/SQM,Averange price |

Send your message to us

Calcium Silicate Boards Model 04 with Good Quality for Wall

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 35000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches